robertst

|

| posted on 6/3/07 at 12:20 PM |

|

|

URGENT help needed with crush tubes

just bought the stainless tube to make the crush tubes and it was f**ing expensive!

well, what do you know, it's smaller than the other ones i had so these rattle slightly inside the polybush.

to give u an idea, 18mm is not a snug fit and these are 17mm.

does the crush tube need a tight fit in the polybush? would this tube i bought expand in any way when torqued up?

basically.... have i just wasted my money? is this absolutely useless?

thanks!

[Edited on 6/3/07 by robertst]

Tom

|

|

|

|

|

Howlor

|

| posted on 6/3/07 at 12:38 PM |

|

|

The tube wont expand but the bush may squeeze onto it when tightened up. You don't want any play though.

Steve

|

|

|

DavidM

|

| posted on 6/3/07 at 12:43 PM |

|

|

quote:

Originally posted by robertst

does the crush tube need a tight fit in the polybush? would this tube i bought expand in any way when torqued up?

basically.... have i just wasted my money? is this absolutely not useful?

thanks!

It does need to be a tight fit. You'd find that the tube is too thick to expand.

Is there nothing else on the car you can use the material for?

David

|

|

|

robertst

|

| posted on 6/3/07 at 12:50 PM |

|

|

17mm diameter, 3mm wall stainless steel? i dont think so. its heavy, can't weld it.

bugger! another day lost!

do you by any chance know the interior diameter needed? i mean 18mm goes fine, but it would rather be 18 point something to be a tight fit.

[Edited on 6/3/07 by robertst]

Tom

|

|

|

robertst

|

| posted on 6/3/07 at 12:58 PM |

|

|

Wait a tick... according to the ANSI wotsits, Stainless steel comes in specific sizes, and specifically to pipes, there is 3/8 in. which is 17mm and

1/2 in. which is 21mm so theres NO WAY of getting an 18mm stainless steel pipe!...

[Edited on 6/3/07 by robertst]

Tom

|

|

|

Peteff

|

| posted on 6/3/07 at 02:28 PM |

|

|

Try looking for tube instead. It is measured by OD and wall thickness. Why does it need to be stainless?

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

robertst

|

| posted on 6/3/07 at 02:36 PM |

|

|

read here not long ago that normal steel ones rust...

what do you mean by tube? a solid one which i will have to drill?

how have people done theirs is what i am dying to know!

Tom

|

|

|

bigandy

|

| posted on 6/3/07 at 02:41 PM |

|

|

Buy the stuff oversize and turn it down to the correct size needed?

Also ANSI standards are American (American National Standards Institute), which is probably why they specify imperial measurements, instead of the

proper metric measurements. You might want to see if the amterial you require is available in metric sizes (i.e. DIN or ISO or BS standards)...

cheers

Andy

Dammit! Too many decisions....

|

|

|

Mr Whippy

|

| posted on 6/3/07 at 02:46 PM |

|

|

quote:

Originally posted by robertst

read here not long ago that normal steel ones rust...

what do you mean by tube? a solid one which i will have to drill?

how have people done theirs is what i am dying to know!

most folk seem to coat them in grease anyway to stop the suspension squeaking, so it won't rust...

mine are all mild steel and I'd bet that most cars are the same.

|

|

|

Bluemoon

|

| posted on 6/3/07 at 02:54 PM |

|

|

Yep mine are Mild steal coated in grease.. And that's the way all standard MK's are done. I would use mild first then change them if they

rust up..

Dan

|

|

|

daviep

|

| posted on 6/3/07 at 02:54 PM |

|

|

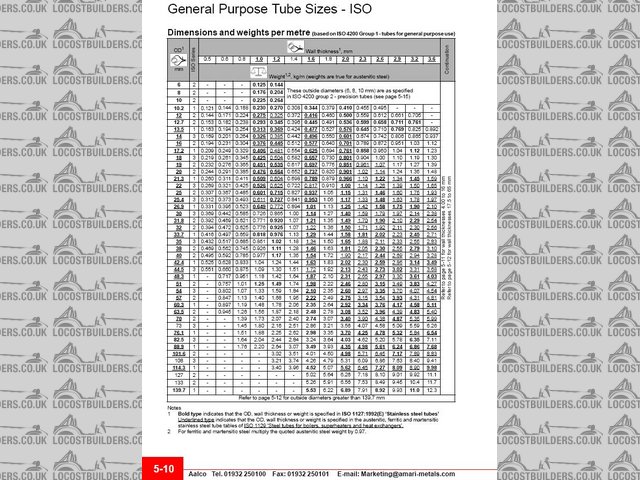

Found this on the aalco website, seems to indicate you can get 18mm stainless tube as a standard size.

Description

Regards Davie

|

|

|

robertst

|

| posted on 6/3/07 at 03:31 PM |

|

|

oh you're a life saver!!!! now i can go complain to my supplier.

should i get 19mm just in case?

just read the LB archives on the crush tube dilemma (didn't now it was a recurring theme ) and the consensus is a tight fit in the polybush. ) and the consensus is a tight fit in the polybush.

Tom

|

|

|

robertst

|

| posted on 6/3/07 at 07:55 PM |

|

|

no luck... steel supplier says there's no such thing as 18 or 19mm stainless (at least in Europe) and so, the next size is 21.3mm diameter. He

did reccomend me to enlarge the hole in the polybush to 21.3mm. any thoughts?

talked to a guy with a lathe earlier on and says he can do it.

Both men asked me the same question: "why stainless steel?" one of them even reccomended bronze or brass (he said it was stronger than

stainless)!!!

also even for this size (21.3mmų 3mm wall) i have to buy all 6 metres of it, so it'll cost me around 100 euros just for the material (of which i

will be just using what, 60cm?).

SHOULD I REALLY BOTHER?! should i just stick with regular steel?

cheers!

[Edited on 6/3/07 by robertst]

[Edited on 6/3/07 by robertst]

Tom

|

|

|

robertst

|

| posted on 6/3/07 at 08:47 PM |

|

|

anyone? i really need your help to decide now as i have to call these guys up first thing tomorrow.

Tom

|

|

|

MikeRJ

|

| posted on 6/3/07 at 09:29 PM |

|

|

I would just go for mild steel to be honest, if you stick plenty of grease on it when assembling it won't rust.

|

|

|

robertst

|

| posted on 7/3/07 at 12:02 AM |

|

|

and it should definitely cost a lot less than stainless.

stainless is more brittle than iron anyways, so its not so good for mechanical purposes (this is the conclusion i didn't understand from the

lathe guy)

thank you very much. i really just needed someone to tell me that because i was starting to chew out the walls...

Tom

|

|

|

James

|

| posted on 9/3/07 at 02:41 PM |

|

|

Most people here have used mild steel AFAIK.... and there's a little more rain here than in Spain!

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|