Findlay234

|

| posted on 10/7/03 at 02:07 PM |

|

|

Tapers....

Ive looked through all the old threads and looked through other websites and not managed to find a solid solution to the problem of tapers in the

sierra stub axle and insert. What im looking for is the taper of the maxi ball joint and the taper of the transit drag link end. Ive asked Luego and

MK and they 'claim' they dont know so that really didnt help.

help please.....

|

|

|

|

|

dozracing

|

| posted on 10/7/03 at 02:58 PM |

|

|

If you look on the files section of the Yahoo Locost list you'll find a drawing i did in PDF format of the Cortina upright, this shows the taper

angles for the maxi (bottom) and the transit (top) ball joint.

Kind regards,

Darren

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

GasGasGas

|

| posted on 10/7/03 at 03:35 PM |

|

|

Tapers

Seem to remeber on a car is born he used a SEVEN degree tapered drill bit to open up the holes a smiggin

He was using Sierra bits???

Anyone else care to confirm or correct????

|

|

|

ChrisW

|

| posted on 10/7/03 at 03:43 PM |

|

|

I was going to say 7.5 degrees but I'm sure somewhere between the two would be fine. I had mine done at a place in West Drayton (behind

SpeedShack) - cost me a drink.

Chris

My gaff my rules

|

|

|

Alan B

|

| posted on 10/7/03 at 03:57 PM |

|

|

Got to disagree here guys....

Yes, the actual figure is between 7 and 7.5 degrees, BUT close will NOT do.....tapers have to match pretty damn accurately....but they will with the

correct reamer....most motor industry tapers are either 1 in 6 or 1 in 8, with 1 in 8 (I.E 1/8" per inch) works out at 7.125016 degrees to 6

DP....

If the taper is not accurate it will only seat at one end causing high contact stresses (Hertzian IIRC), or creep which will cause loseness and

movement......

Bottom line....tapers must fit well...if any rock can be felt it is not close enough.

|

|

|

jonti

|

| posted on 10/7/03 at 04:34 PM |

|

|

Seem to remember on a car is born he used a SEVEN degree tapered drill bit to open up the holes a smiggin

He was using Sierra bits???

Anyone else care to confirm or correct????

You are correct the muppet vet on CIB did use a 7degree taper drill for the track rod ends cos he was reversing them...I intended to do the same and

have my balls upside down too (oo er missus) cos the racks a bit higher than the steering arm. However, couldnt find such a drill anywhere so

they're still the same way up at the moment. Dunno if BMC would be the same taper though.

OFROK

|

|

|

Mark Allanson

|

| posted on 10/7/03 at 05:23 PM |

|

|

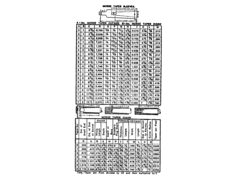

This may be exactly what you are looking for - or a total load of b*ll*cks

Rescued attachment Taper.GIF

|

|

|

stephen_gusterson

|

| posted on 10/7/03 at 05:52 PM |

|

|

I very roughly calculated the taper of a cortina and sierra at the start of my build, by measuring entry and exit hole dia on the hubs, and the

distance between them. A bit of trig worked out approx angles.

I thought it was 2.5 and 4 degrees - but could have been 4.5 and 6 - point is they are quite different.

Make up two card templates, scaled up, and you will see that with that kind or error, there is only a tiny point of contact between the two mating

sufaces. As alanB has inferred, looks like a guaranteed shear point to me.

atb

steve

[Edited on 11/7/03 by stephen_gusterson]

|

|

|

dozracing

|

| posted on 10/7/03 at 08:58 PM |

|

|

I say again, look at my cortina drawing on teh yahoo site and you'll see the drawing i made of the tapers in the upright as measured by a CMM

machine.

No need to guess when you have 50k's worth of measuring machine to do it for you.

Kind regards,

Darren

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

Findlay234

|

| posted on 11/7/03 at 08:39 AM |

|

|

Sorry darren i cant find it on the yahoo lists including locost, locost_uk, locost oz, locost theory. Nor can i find it on the locost mirror/file

server site. I can find some dwg files but they dont work with my system(AutoCAD 2000i).

Any chance you can post that file in pdf on this site?

cheers

Fin

|

|

|

dozracing

|

| posted on 11/7/03 at 10:45 AM |

|

|

Hi,

Send me an email offlist to remind me and i'll send it to you direct.

Darren@gtstuning.co.uk

Kind regards,

Darren

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

ChrisW

|

| posted on 11/7/03 at 01:11 PM |

|

|

Darren

Are you able to cut these tapers? I'm a bit worried about mine now (we didn't do it particularly acurately!!)

Chris

My gaff my rules

|

|

|

dozracing

|

| posted on 11/7/03 at 04:32 PM |

|

|

Yeah we can probably cut them, i'll ask my machinist and let you know.

Kind regards,

Darren

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blueshift

|

| posted on 11/7/03 at 04:54 PM |

|

|

I have no idea what this conversation is about but it seems serious, and that worries me.

do I need to know what this is about?

|

|

|

Rorty

|

| posted on 12/7/03 at 02:19 AM |

|

|

blueshift:

quote:

do I need to know what this is about?

Yes, and I'd read the entire thread again, if I were you, till you fully understand the implications.

You've little to worry about if you're using factory parts that are either designed for each other, or are directly interchangeable with

the parts you are using.

If you've messed with either your BJ tapers or taper sockets, then you run the very real risk of failure.

Only when the taper and socket mate perfectly, and for their full lengths, will their integrity and strength be suitable.

Alan made reference to this about 10 posts back.

Motor engineers design parts and methods for valid reasons, not just to make it difficult for locost builders.

Disregard at your peril!

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

jcduroc

|

| posted on 12/7/03 at 11:18 PM |

|

|

quote:

Originally posted by Alan B

Yes, the actual figure is between 7 and 7.5 degrees, ... most motor industry tapers are either 1 in 6 or 1 in 8, with 1 in 8 (I.E 1/8" per inch)

works out at 7.125016 degrees to 6 DP....

The Transit Rod End is tapered 1/8; so is the Cortina lower balljoint (according to Quinton Hazell

Joćo.jpg)

|

|

|

kingr

|

| posted on 13/7/03 at 12:01 AM |

|

|

One problem, that's a transit TRE, not a transit drag link (the M20 thread rather than M18 is the giveaway).

Kingr

|

|

|

Findlay234

|

| posted on 13/7/03 at 12:40 PM |

|

|

The drag link and the cortina/maxi balljoints have the same taper as shown by darrens drawing. If i remember my calculations they were about 7.06deg

so a 7deg taper should be the one to go for, cheers darren

|

|

|

jcduroc

|

| posted on 13/7/03 at 05:02 PM |

|

|

quote:

Originally posted by kingr

One problem, that's a transit TRE, not a transit drag link (the M20 thread rather than M18 is the giveaway).

Kingr

What is a drag link?

Joćo

|

|

|

Peteff

|

| posted on 13/7/03 at 05:11 PM |

|

|

What is a drag link?

It's a coupling used on the older steering box systems from the mk1 and 2 transits before they went over to rack and pinion steering. They were

handed with a left and right hand thread and only the right hand threaded one is used for both sides on the locost.

yours, Pete.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

stephen_gusterson

|

| posted on 13/7/03 at 06:50 PM |

|

|

its a system where there isnt a rack, just a bar across between the steering arms on the hubs. A steering box then has an arm that comes down from it

that 'drags' the bar left to right, moving the wheels with it.

thats my understanding - i think mk1 cortinas had it.

atb

steve

|

|

|

Spyderman

|

| posted on 13/7/03 at 08:33 PM |

|

|

Much the same as a VW Beetle then!

No not the new one!

Spyderman

|

|

|

jcduroc

|

| posted on 14/7/03 at 10:45 AM |

|

|

quote:

Originally posted by Peteff

It's a coupling used on the older steering box systems from the mk1 and 2 transits before they went over to rack and pinion steering. They were

handed with a left and right hand thread and only the right hand threaded one is used for both sides on the locost.

yours, Pete.

quote:

Originally posted by Stephen

its a system where there isnt a rack, just a bar across between the steering arms on the hubs. A steering box then has an arm that comes down from it

that 'drags' the bar left to right, moving the wheels with it.

thats my understanding - i think mk1 cortinas had it.

Thank you Pete, Steve and Dancing Spyder

So the drag link that kingr says is M18 instead of my TRE M20 goes at:

a) either end of the bar from side to side or

b) links the steering box to that same bar?

Cheers, Joćo

|

|

|