blueshift

|

| posted on 11/1/07 at 04:26 PM |

|

|

Brass in wishbone jig, how much heat can it take?

Hello folks, been a long time but I'm back in the garage and picking up the same problem that pissed me off months ago.

I made some bent top wishbones with a crap jig, have chopped and ressurected them as parts for new bones, now want to get it right.

Have pondered making a big bombproof jig that holds everything in place, but can't think how to make one that still gives me good access for

welding.

So I think to myself, it doesn't really matter if the balljoint tube is a bit out of line, it will still be in the right place to within a

couple of mil, it's the alignment and to a lesser extent the spacing of the bush tubes that matters.

So what I'm thinking of now is use my wooden jig to hold the parts while I tack them, then use the brass inserts and rod technique to hold the

bush tubes in line (possibly mounted on a chunk of steel for more rigidity)

I know brass inserts have been used by folks here, my question is how much heat can they take, presumably you can weld tubes that they are inside..

what if I use lots of heat and the steel melts next to the brass?

also, I fancy using the technique of heating the bones cherry-red then putting in the oven to cool off (I seem to remember Mark Allanson did that with

good results), will the brass handle the heat?

Nice to be back in the garage and back on here  Hope everyone's builds are going better than mine.. Hope everyone's builds are going better than mine..

|

|

|

|

|

3GEComponents

|

| posted on 11/1/07 at 04:33 PM |

|

|

We often use a brass block behind flat plate when we plug holes, it leaves the underside flat, with little or no preperation required.

|

|

|

James

|

| posted on 11/1/07 at 04:40 PM |

|

|

He's back!

Good to see you back on list.

Can I recommend doing the bush tubes from one long piece and then cutting out the middle section. This worked for me and they seem to be straight.

HTH,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

flak monkey

|

| posted on 11/1/07 at 04:53 PM |

|

|

Depending on the alloy, brass melts at 900 deg. Steel at 1600 ish. Cherry red in steel is anwhere from about 640 upwards IIRC. So you will be ok.

Its common when making neat welds to place a bit of copper or brass next to or under the weld as the weld wont stick to it, so dont worry about that

either. Seen it done several times and they havent had any trouble.

David

Sera

http://www.motosera.com

|

|

|

blueshift

|

| posted on 11/1/07 at 04:57 PM |

|

|

Cool, those are the kind of answers I was looking for, cheers. I'll bring a tube in tomorrow and go and see the engineering guy on the

industrial estate.

James, you've finished your car! congrats, it looks really nice.

I would consider the cutting from a length of tube thing, but I've already got ones cut to size from GTS and all jigged up etc.

|

|

|

Volvorsport

|

| posted on 11/1/07 at 07:05 PM |

|

|

aluminium is a good heat sink if you need to heat away from the area .

my jig involved clamping the bush tubes into placeon a simple T shaped jig , gives enough space to weld both sides enough before you take it out the

jig and finish it off .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

907

|

| posted on 11/1/07 at 07:33 PM |

|

|

Hi.

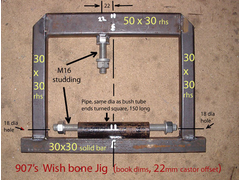

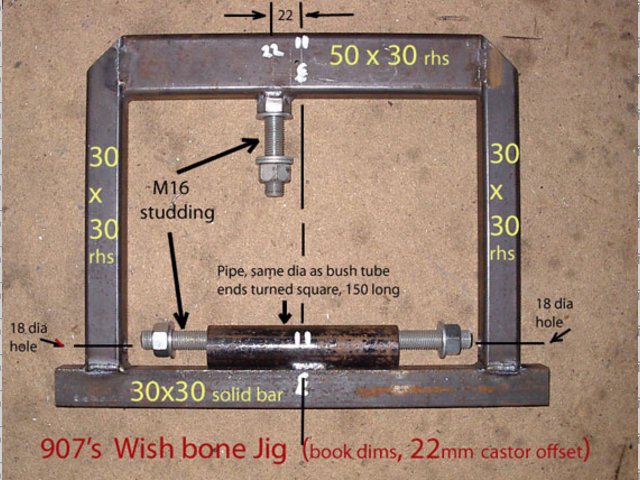

I made my jig as in the pic below.

Looks like I approached the task the opposite way to Volvorsport.

It proves there's more than one way to skin a cat.

Paul G

Rescued attachment 22mm-w-b-jig-s.jpg

|

|

|

NS Dev

|

| posted on 12/1/07 at 07:59 AM |

|

|

brass will be fine, won't melt unless you get the whole bush tube orange.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|