tks

|

| posted on 3/11/06 at 08:13 AM |

|

|

Sierra diff flange specs

I have some confusing regarding the sierra dif flange.

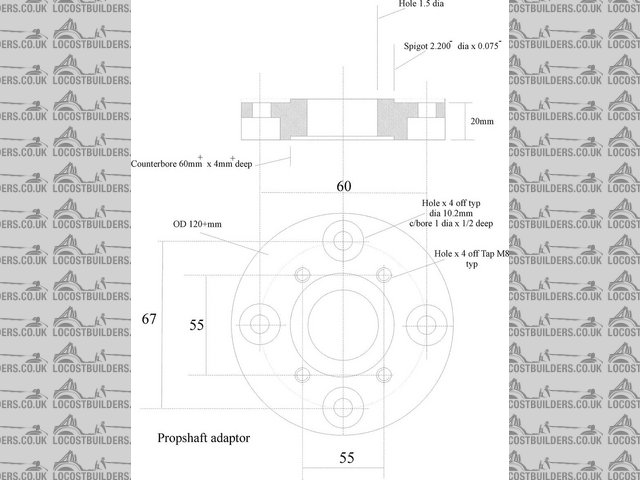

Because on this site this drawing flies arround but its not right?!? does anyone have another one?

for non UK diffs?

Tks

Sierra flange specs

Looks like the dimensions are true but the way they are quoted not.

Should be a square not??

The above comments are always meant to be from the above persons perspective.

|

|

|

|

|

NS Dev

|

| posted on 3/11/06 at 09:50 AM |

|

|

see what you mean, if indeed that drawing is for something that is supposed to bolt to a sierra diff flange then it won't, because as you say,

the holes are not equididistant. (they are in a rectangle not a square)

Unfortunately I don't have a drawing!!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

tks

|

| posted on 3/11/06 at 10:39 AM |

|

|

OK

Guess this drawing is from JOELP or flat monkey one of the 2. i ripped it from their archive.

Anyways do you agree the numbers 60 and 67?? I imagine that the square is 30 of center and 33,5 of center.??

its for lasercutting my reverse gear piñion.

in fact you could help me saying what you think about the thickness of the sheet

for a bit of reverseing..

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

NS Dev

|

| posted on 3/11/06 at 12:15 PM |

|

|

I'll have a measure for you later if I get the chance.

If you can keep the dia down go for 10mm thick for the gear.

Lasercut will work a treat, gives a slightly hard edge which helps it nicely!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

tks

|

| posted on 3/11/06 at 12:25 PM |

|

|

jajaja

I´m starting to like you! you over design sow my coupling/clutch should be goood for sure!!!

10mm puff only for a bit of reverse its way to much!

@ 10mm the laser cut is bad! and they use a 5Kw laser machine. that means max alloy = 10mm but the cut is bad!

i have order 6mm steel. we will see. it only weight 0,7Kgs did you see the drawing in the other topic?

to harden you need to add carbon and you need to cool down rapidly.

anyway i know what you mean, you refer to the blueish colour at the border.

Tks

[Edited on 3/11/06 by tks]

The above comments are always meant to be from the above persons perspective.

|

|

|

indykid

|

| posted on 3/11/06 at 03:49 PM |

|

|

wrt the original question, a prop will only bolt to a sierra diff one way (2 out of 4 ways if you're being pedantic) so the holes must not be on

the same pcd.

i can't guarantee the measurements, but they're definitely not all the same pcd.

tom

|

|

|