mistergrumpy

|

| posted on 25/9/06 at 09:45 PM |

|

|

Front Wishbones

Just wondered really, out of curiosity. How many people are using DIY front wishbones i.e. bottom bone with plate welded on top, angles changed or

whatever. Just noticed a lot appearing on Ebay lately, a few sold by a member of this forum. I'm getting mine from GTS personally after seeing

the failures on some home made ones and just that I think that these are quite critical parts.

|

|

|

|

|

nitram38

|

| posted on 25/9/06 at 10:08 PM |

|

|

Mine are DIY, but I don't think that they will fit your car!!!!!!!!!

|

|

|

mistergrumpy

|

| posted on 25/9/06 at 10:17 PM |

|

|

|

|

|

nitram38

|

| posted on 25/9/06 at 10:22 PM |

|

|

More seriously though, whatever you use, make sure that the top wishbone is set back towards the back of the car to give you a good enough castor

angle, for proper self centering. Not the secondary bodges of toe out and under inflated tyres.

Do a search.

Martin

|

|

|

mark chandler

|

| posted on 25/9/06 at 10:27 PM |

|

|

I made mine, as above check the forum as the standard design is flawed in more than one area.

When something is wrong and sold in enough quanties it becomes right !

|

|

|

zetec7

|

| posted on 25/9/06 at 10:30 PM |

|

|

I made mine because I don't trust any of the pre-made ones!!!

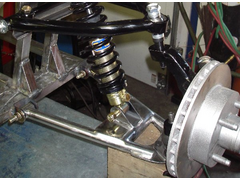

Rescued attachment lower bone.jpg

|

|

|

GeoffT

|

| posted on 25/9/06 at 10:30 PM |

|

|

I'm using DIY book wishbones (19mm x 1.6 erw tube) and despite a few tyre smoking 'brake tests' and 3000 miles, I've never

managed to bend them. Never been happy with them though, and one of the jobs on my 'to do' list is make up some new bottom bones using

22mm x 2.0.

When I do I'll probably stick the old ones on Ebay.....

|

|

|

mistergrumpy

|

| posted on 25/9/06 at 10:41 PM |

|

|

No, don't get me wrong. Like I said, I'm gonna buy them as I know their tolerances and what not will be better than mine and I think

wishbones are quite important, stresses and the like, but most people seem to slate home made ones on here and I've seen the photos of the

failures but I figured that someone must be using them as they're certainly selling on Ebay. False economy or not?

|

|

|

SkinnyG

|

| posted on 26/9/06 at 04:17 AM |

|

|

Made my own.

1" x .095" DOM (I guess that's 25mm x 2.4mm?)

G

The Lethal Locost

|

|

|

johnemms

|

| posted on 26/9/06 at 07:52 AM |

|

|

Remember... the stronger the wishbone ... the more chance of rippin yer chassis to bits if u curb it ..... if i ever get it wrong on a corner i hope

its just the wishbones i have to replace and not carve up the chassis.....

|

|

|

nitram38

|

| posted on 26/9/06 at 07:55 AM |

|

|

You also don't want them to just fold over a small bump do you?!

|

|

|

mistergrumpy

|

| posted on 26/9/06 at 08:32 AM |

|

|

quote:

Remember... the stronger the wishbone ... the more chance of rippin yer chassis to bits if u curb it

Interesting. Never thought about it like that. As Nitram says though you wouldn't want them folding over a bump. So I guess quite a few people

do make/use home made bones. I thought the general consensus on here was to buy them. Some good pictures/work by the way.

|

|

|

James

|

| posted on 26/9/06 at 09:28 AM |

|

|

Home-made and proud!

Although some new lowers are on the 'to do' list!

Cheers,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

nitram38

|

| posted on 26/9/06 at 09:56 AM |

|

|

My front bones are about twice the length of a locost, so the stresses are greater. My tubes are 25mm dia 3mm wall CDS tube.

|

|

|

DavidM

|

| posted on 26/9/06 at 12:01 PM |

|

|

I made my own. No problems so far.

I think the design of some bones have been slated on here, rather than the fact that they were or weren't home made.

There haven't actually been that many failures posted on here (probably 2 or maybe 3), but I seem to remember that of those that were, at least

one was bought from a well known manufacturer.

I've seen wishbones fitted to cars on manufacturers stands that I would think twice about putting on my car.

David

Proportion is Everything

|

|

|

NS Dev

|

| posted on 26/9/06 at 12:34 PM |

|

|

quote:

Originally posted by mistergrumpy

No, don't get me wrong. Like I said, I'm gonna buy them as I know their tolerances and what not will be better than mine and I think

wishbones are quite important, stresses and the like,

Heh Heh!!!!! that made me laugh out loud!!!

People only slate crap home made ones!!!!

Don't, whatever you do, think that "professionally made" wishbones are accurate, and certainly don't think that they are

better than home made ones (assuming you can weld to a very good standard)

I would stake my life on my own wishbones much more readily than most "professionally made" ones!

If you really want a nice job doing you go to somewhere that charges a bit more money and makes nice parts.

Two people on here to speak to are Nick Skidmore and Matt Gilmour (Procomp) both do quality fabrications.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

mistergrumpy

|

| posted on 26/9/06 at 05:19 PM |

|

|

Well I was looking at the GTS ones cos I've seen these and they do look good but to be honest are a bit expensive (or maybe I'm just a bit

skint  ) My welding's good but not very good but maybe I might have a bash? Would really like to do them myself, but what plans/dimensions?

Same as book but with the correct castor of course? Have done loads of searches on this, driving me mad. ) My welding's good but not very good but maybe I might have a bash? Would really like to do them myself, but what plans/dimensions?

Same as book but with the correct castor of course? Have done loads of searches on this, driving me mad.

|

|

|

omega 24 v6

|

| posted on 26/9/06 at 05:28 PM |

|

|

quote:

Remember... the stronger the wishbone ... the more chance of rippin yer chassis to bits if u curb it ..... if i ever get it wrong on a corner i hope

its just the wishbones i have to replace and not carve up the chassis.....

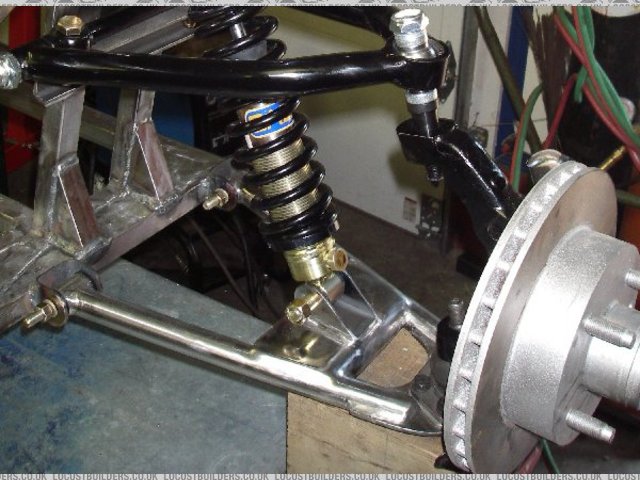

I've made my own from 25*3 cds and as above quote I'm thinking about downgrading the weight/strength. Some piccies in the archive if you

want a look.

|

|

|

mistergrumpy

|

| posted on 26/9/06 at 05:42 PM |

|

|

^Cheers, will do now^

|

|

|

mistergrumpy

|

| posted on 26/9/06 at 06:07 PM |

|

|

Good job there Omega. Mind me asking what that 10mm gap between the brackets and mounts was about? I've not even thought about mounting them yet

but have held back from welding in the uprights yet.

|

|

|

Mark Allanson

|

| posted on 26/9/06 at 08:15 PM |

|

|

I think a really over simplified view of lower wishbones, is that the distance between the balljoint centre and the shock lower pick up be as short as

possible (less leverage for bending forces), and that the reinforcing plate has a nice curve to defocus the same bending forces.

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

omega 24 v6

|

| posted on 26/9/06 at 09:03 PM |

|

|

quote:

Mind me asking what that 10mm gap between the brackets and mounts was about?

Well I'm building a 442 and the front geometry of the chassis does not lend itself to the wishbone mounts as per the book and various other

sizes/combinations found in other threads here.

I think you'll be ok with a book chassis (THINK) but your right to only stich everything until your sure.

|

|

|

mistergrumpy

|

| posted on 26/9/06 at 09:06 PM |

|

|

Yeah just got that from me searches, been at them for hours  Ah well, knowledge is power so they say. Except I think all this beer I've been

drinking while searching is gonna cancel that out. Ah well, knowledge is power so they say. Except I think all this beer I've been

drinking while searching is gonna cancel that out.

|

|

|