TPG

|

| posted on 18/7/06 at 12:45 PM |

|

|

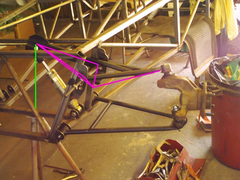

Opinions and views please.

One for all the budding suspension gurus out there.I'm fairly settled on this.Is there anything obviously really badly badly realy

wrong?I'll be putting proper bolts etc in.....

Its rocking arm.For every inch of travel on the hub the shocker moves an inch etc etc.

Before I make the other side,Just need to be sure.

Thanks.

Richard.

Rescued attachment Rocker1small.jpg

..Which was nice..

|

|

|

|

|

TPG

|

| posted on 18/7/06 at 12:52 PM |

|

|

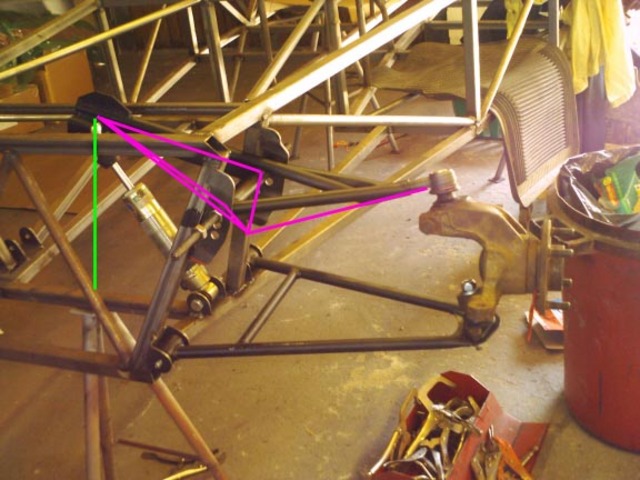

From another angle.

Rescued attachment Rocker3small.jpg

..Which was nice..

|

|

|

ayoungman

|

| posted on 18/7/06 at 01:32 PM |

|

|

Is the tube that transmits the force to the inboard coilover beefy enough ? I've looked at F27 inboard suspension and that uses a fairly

substantial box section tube for that part.

Just a thought.... HTH

"just like that !"

|

|

|

02GF74

|

| posted on 18/7/06 at 01:36 PM |

|

|

sorry to ask but do you know what you are doing? I would have expected both upper and lower wishbones to be the same length so when the wheel goes up

or down, it moves in a vertical line (think parallelogram). Seems in your design the wheel is going to rotate ... but hey, what do I know about

suspension

|

|

|

andyharding

|

| posted on 18/7/06 at 01:41 PM |

|

|

I think you'll bend your top bone. It just doesn't look strong enough.

Are you a Mac user or a retard?

|

|

|

Mad Dave

|

| posted on 18/7/06 at 01:42 PM |

|

|

Unequal length wishbones give you camber gain which helps increase cornering power (is that the right word?).

|

|

|

MikeRJ

|

| posted on 18/7/06 at 02:02 PM |

|

|

quote:

Originally posted by 02GF74

sorry to ask but do you know what you are doing? I would have expected both upper and lower wishbones to be the same length so when the wheel goes up

or down, it moves in a vertical line (think parallelogram). Seems in your design the wheel is going to rotate ... but hey, what do I know about

suspension

Have you ever checked the wishbones on your car? If wishbones are set up like a parallelogram they give silly amounts of camber change in roll,

because the camber angle of the wheel exactly tracks the roll angle of the chassis

Two things concern me about this setup:

One is the top wishbone simply doesn't look strong enough. Either a proper triangulated structure is required to keep everything in

tension/compression, or the tubes need to be considerably beefed up to handle the bending loads.

Secondly, there has been considerable discussion on the use of the transit drag link for this type of applicaton and IIRC the conclusion was that is

is simply not strong enough. As an added problem, applying force into the balljoint in the direction that this suspension does could lift the ball of

it's seat which will allow undesired movement.

Also, if you are going to use a rocking arm, why not mount the shocks verticaly? This allows you to use lighter springs and allow the damper to work

more effectively.

[Edited on 18/7/06 by MikeRJ]

|

|

|

Marcus

|

| posted on 18/7/06 at 02:36 PM |

|

|

I agree with Mike re unequal wishbones. EVERY locost / MK / MAC1 /MNR etc have unequal length for camber change when the body rolls.

With the shock at that angle will the spring rate fall off very rapidly as the suspension moves up?

Marcus

Because kits are for girls!!

|

|

|

02GF74

|

| posted on 18/7/06 at 02:49 PM |

|

|

quote:

Originally posted by MikeRJ

quote:

Originally posted by 02GF74

blah blah blah ... but hey, what do I know about suspension

Have you ever checked the wishbones on your car?

no; I'm sure you're right; will take a peak tonight

oh, and making the chassis from gold is not gonna be locost!

[Edited on 18/7/06 by 02GF74]

|

|

|

Mr Clive

|

| posted on 18/7/06 at 03:01 PM |

|

|

My concerns would be 3 things.

Firstly, does the geometry enter severe falling rate as the upright nears full bump?

Secondly, the top wishbone doesnt quite look strong enough. The top bar, that runs from the shock pivot to the upright doesnt seem to be close enough

to the outboard rod end.

finally, the top rod end is going to be subjected to very large bending loads. I would be concerned about its strength, particularly as it is a

critical part.

Thats only my opinions after a quick look at the photos though.

|

|

|

leto

|

| posted on 18/7/06 at 03:50 PM |

|

|

Nothing new here:

The top wishbone and brackets might be strong enough, or might not.

As MikeRJ say, the transit ball joint is not designed for the loads.

And the angle of the shock is way out, a.o. significantly increasing the loads on the pivot.

Bushes/bearings/brackets take mush higher loads with a rocker arm, standard bushes might be to weak.

Nice work anyhow

“I'm gonna ride around in style

I'm gonna drive everybody wild

'Cause I'll have the only one there is a round”. (J. Cash)

|

|

|

TPG

|

| posted on 18/7/06 at 03:58 PM |

|

|

Thank you gentleman.

The book wishbones are uneqaul.uneeeqwe.....Not the same length.....

Regards the rocking arm.Thinking back to the lower arm bending issues that have happened,these were mainly down to where and how the gusset

finished/fitted.

I have added bracing top and bottom for strength.Not very clear in the pictures.My thinking is on my other car the lower wishbones had similar forces

applied to them further from the pivot points and i myself(Engage smug mode) didn't have any problems with strength.I have bounced my old car

through Yorkshire dales potholes and genrally poor roads,even airborne at Brimham Rocks(Anyone who knows it..) and not had a bracket or wishbone

go,even when it was entitled to.I am still thinking of putting 1" tube in though....

The transit link is a problem.It lacks a large degree of movement.It is the arc of movement limiting factor in locost.I'm trying to sort

something on that.On my old car I had poor droop(O er Miss's)and limited compression.

I am not right up to speed on rates etc.The shocks are at a similar angle to the rocker arm as they are on a lot of other se7ens.Thats my only theory

at the moment....

Please keep the coments and suggestions coming.They are welcome and helpful.Thankyou

Richard.

[Edited on 18/7/06 by TPG]

[Edited on 18/7/06 by TPG]

..Which was nice..

|

|

|

ady8077

|

| posted on 18/7/06 at 05:02 PM |

|

|

Hi

the Striker and Fury use a simple rocker system, they have the shock more vertical

Adrian

Rescued attachment in suspension.jpg

|

|

|

bimbleuk

|

| posted on 18/7/06 at 05:04 PM |

|

|

In your design wouldn't you take a line perpendicular to the uppper middle rocker arm. So the coilover would have the bottom end much further

inside the chassis. Basically so the thrust from the rocker arm is straight down the centre of the damper?

The striker upper rocker arm has quite similar geomrtry even though the construction very different.

Roller rockers - top

|

|

|

bimbleuk

|

| posted on 18/7/06 at 05:04 PM |

|

|

*SNAP*

|

|

|

JoelP

|

| posted on 18/7/06 at 05:45 PM |

|

|

nicely made, but id expect it to bend too. Id do it like this myself, and would be confident that it would last even in 19mm 16g tubing.

|

|

|

TPG

|

| posted on 18/7/06 at 06:16 PM |

|

|

The fisher stuff is the idea behind.I'm just trying to reinvent the wheel,or rocker in this case . .

Using cds I think i'm getting near the required strength.

The fisher design is fantastic.Class leading.1000's circuit and hillclimb winners can't be wrong.

As Joel has drawn,this is what I was aiming at.But doing the 'rod from there and keeping it straight and in one piece(See what i'm doing

there? )It left the space to fit the coilover very small an exspensive one off shocker size.I'm using standard book for cost.. )It left the space to fit the coilover very small an exspensive one off shocker size.I'm using standard book for cost..

Thanks

..Which was nice..

|

|

|

bimbleuk

|

| posted on 18/7/06 at 06:29 PM |

|

|

Maybe you should just try it. After all you are doing the work yourself so the cost is minimal. If we don't try things a little different

we'd all still be driving lotus 7s!!

Remember that kit car prog on TV where that muppet built a kit car. That was easy to test so finish the front end and jump up and down on the bugger

|

|

|

zetec7

|

| posted on 18/7/06 at 06:45 PM |

|

|

I have to agree - the bones don't look strong enough for their length. There have been previous threads about bones bending/breaking under

stress (if you get the chance you might want to pick up the Aug.'06 copy of Car & Driver magazine to see the results of this...). We were

worried about this as well, and made ours very strong....

Rescued attachment front suspension.jpg

|

|

|

TPG

|

| posted on 18/7/06 at 07:18 PM |

|

|

quote:

Originally posted by bimbleuk

Maybe you should just try it. After all you are doing the work yourself so the cost is minimal. If we don't try things a little different

we'd all still be driving lotus 7s!!

Bang on the nail!!To me this is the true spirt of Locosts.

Thanks.

|

|

|

mark chandler

|

| posted on 18/7/06 at 09:33 PM |

|

|

I,d try but that TRE is going to suffer, its designed for lateral forces not vertical so you need a decent ball joint IMHO.

TRE's are preloaded with a spring, if you pop it into a vice you should be able to easily depress the pin, a ball joint is shimmed and solid.

Regards Mark

|

|

|

JoelP

|

| posted on 18/7/06 at 09:47 PM |

|

|

you could just replace it with a rosejoint, and drill the upright to take a bolt rather than a taper. Raceleda do a thread adapter, or you could whip

one up on a lathe.

|

|

|

chriscook

|

| posted on 18/7/06 at 09:52 PM |

|

|

quote:

Originally posted by TPG

It left the space to fit the coilover very small an exspensive one off shocker size.I'm using standard book for cost..

Surely the length wouldn't be that short, the fury, striker and phoenix all have the same rocker arrangement and use off the shelf dampers.

I'd also be very worried about the strength of your rocker as it is it is in bending and tension. It may be strong enough to survive one off

events but from a fatigue point of view I can see the 'tear here' dotted line.

If you are going to keep the same geometry then i'd also make the bottom damper mounts wider to spread the load more if you see what I mean.

|

|

|

leto

|

| posted on 19/7/06 at 06:00 AM |

|

|

This will be almost as good and you can build it in an angle, so no problem with length of the shocks. Loads within the structure will increase with

the angel so try to keep the arm it as straight as possible.

Rocker

You will get something like twice the load in rocker arm, compared to a standard lower wishbone.

“I'm gonna ride around in style

I'm gonna drive everybody wild

'Cause I'll have the only one there is a round”. (J. Cash)

|

|

|

02GF74

|

| posted on 19/7/06 at 10:08 AM |

|

|

quote:

Originally posted by TPG

quote:

Originally posted by bimbleuk

Maybe you should just try it. After all you are doing the work yourself so the cost is minimal. If we don't try things a little different

we'd all still be driving lotus 7s!!

Bang on the nail!!To me this is the true spirt of Locosts.

Well I think that is very dangerous encouragement. Steering and brakes are something you do not eff about with. Think about the original 7

development; engines were a lot less powerful than today's, roads had fewer cars and testing most likely done on a track not on the roads.

Should something go wrong with the design at speed what is going to happen? (small clue: instant death!)

Don't be discouragedThe idea is sound - rocker suspension, well it rocks!

There have been what appear cirticisms/ etc: but that is what you asked for plus if it saves your life, it ain't that bad is it?

quote:

Originally posted by mark chandler

I,d try but that TRE is going to suffer, its designed for lateral forces not vertical so you need a decent ball joint IMHO.

TRE's are preloaded with a spring, if you pop it into a vice you should be able to easily depress the pin, a ball joint is shimmed and solid.

Regards Mark

Have you ever taken a tre apart? I have, an LR one, It is a spring pressing on a socket for a ball; all that holds it together is a swaged over

cover - as folks have said, it isn't going to take much vertical force to break.

|

|

|