gjs

|

| posted on 15/6/06 at 02:40 PM |

|

|

how to shorten driveshafts?

Anyone done this at home with sierra shafts,or know of any sites that show how to do it etc

[Edited on 15/6/06 by gjs]

|

|

|

|

|

rusty nuts

|

| posted on 15/6/06 at 04:49 PM |

|

|

Luego used to shorten them for the IRS Locost , they did mine but I think if I were to build another with shortened drive shafts I would get new ones

made . Think it was NSDev who posted a link for driveshaft manufacturers. May be worth a search?

|

|

|

NS Dev

|

| posted on 15/6/06 at 05:04 PM |

|

|

GB Engineering

01270 841081

£80 each machined from billet, lightweight, heat treated EN27

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

trikerneil

|

| posted on 15/6/06 at 05:07 PM |

|

|

Have a look HERE.

But I've only got 95BHP in 350Kgs

ACE Cafe - Just say No.

|

|

|

gjs

|

| posted on 15/6/06 at 05:40 PM |

|

|

Cheers guys for the replies

|

|

|

Mr G

|

| posted on 15/6/06 at 06:10 PM |

|

|

MK Engineering do them as well.

If the only option is shortening standard ones yourself then make sure you sleeve them.

Normal is getting dressed in clothes that you buy for work and driving through traffic in a

car that you are still paying for - in order to get to the job you need to pay for the clothes

and the car, and the house you leave vacant all day so you can afford to live in it.

|

|

|

JB

|

| posted on 15/6/06 at 07:26 PM |

|

|

Shortening Driveshafts

I have never done this but it should work.

The problem with drive shaftsis welding is not really advised due to the steel involved.

Therefore you can sleeve the outside and use 638 Loctite high strength retainer. If you get enough surface area it should hold.

The other option is silver solder. It will wick in and hold.

Anybody brave enough to try it?

Obviously surface finish and prep is vitally important, as is making sure they are straight.

If anybody is seriously interested I will explain how I would do this.

John

|

|

|

Wadders

|

| posted on 15/6/06 at 08:08 PM |

|

|

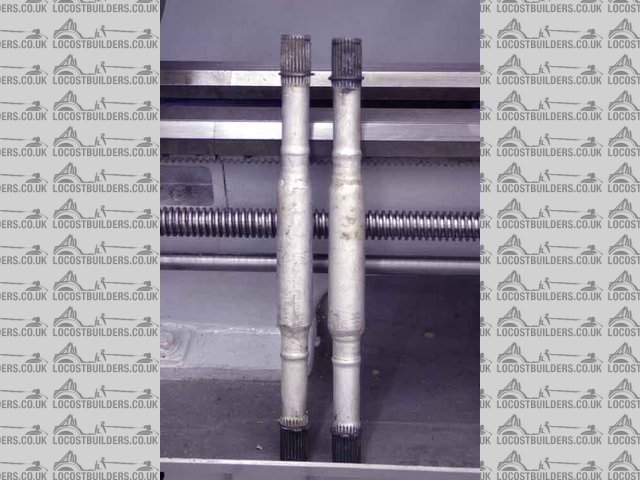

All Stuart Taylors use shortened, sleeved and welded shafts, in fact i happen to have a pair for sale if your interested.... they are splined for

lobros both ends. they are splined for

lobros both ends.

|

|

|

russbost

|

| posted on 15/6/06 at 09:35 PM |

|

|

Trust me - driveshafts can certainly be welded, I welded mine myself & I've broken a couple of bits in the drivetrain but not those, (see my

thread under bec - bike engines have no torque ???!!!).

If they are solid steel. cut them get some interference fit sleeves, join at required length & a quick bead of weld at max power, Bob's your

uncle, Fannys your aunt & away you go laughing

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

gjs

|

| posted on 15/6/06 at 10:01 PM |

|

|

Hey Wadders can you post a pic of the shafts u have for sale

cheers

|

|

|

Wadders

|

| posted on 15/6/06 at 10:58 PM |

|

|

Will do it tommorow, no problem.

Originally posted by gjs

Hey Wadders can you post a pic of the shafts u have for sale

cheers

|

|

|

Wadders

|

| posted on 17/6/06 at 09:26 PM |

|

|

Pic as promised, sorry for the delay.

Description

|

|

|