Avoneer

|

| posted on 4/8/05 at 08:08 PM |

|

|

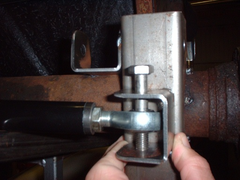

Panhard rod bracket orientation

Hi,

Is this the best orientation for the bracket for my panhard rod?

Pat...

Rescued attachment 1.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

|

|

Avoneer

|

| posted on 4/8/05 at 08:08 PM |

|

|

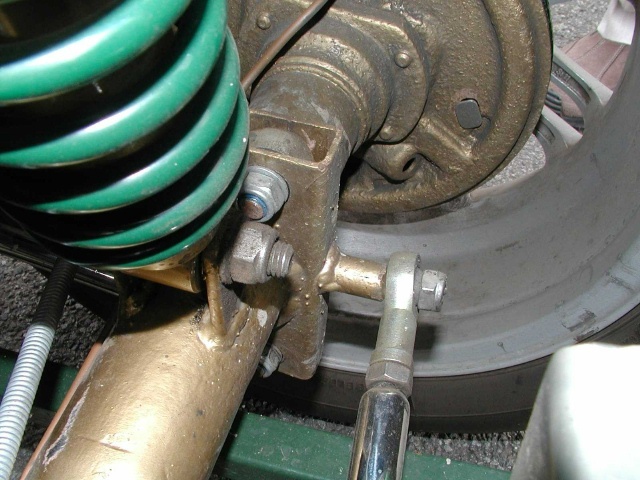

Pic 2:.JPG)

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

JoelP

|

| posted on 4/8/05 at 08:17 PM |

|

|

IMHO, i believe so. The alternative would be to only have one side of the bracket welded on, and i can see nothing else to chose between the two ways

(ie that way up or rotated 90 degrees).

|

|

|

Fozzie

|

| posted on 4/8/05 at 08:41 PM |

|

|

ooeer Pat,  , think about how axle moves in relation to panhard rod....you might want to turn it 90degs (bracket)... , think about how axle moves in relation to panhard rod....you might want to turn it 90degs (bracket)...

IMO you need to turn the bracket in your hand over 90 degrees, and put it next to the link bracket.

Fozzie

[Edited on 4/8/05 by Fozzie]

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

JoelP

|

| posted on 4/8/05 at 08:46 PM |

|

|

rod ends move ok in that direction too dont they fozzie?! surely the few degrees would be ok.

|

|

|

Fozzie

|

| posted on 4/8/05 at 09:30 PM |

|

|

The misalignment angles of the rose joint are not sufficent to allow the axle to move through its complete travel. The biggest misalignment angles are

probably about 30 degs, but of course depends on the rose joints you have got. Best to check with manufacturers

HTH Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

nanosleep

|

| posted on 4/8/05 at 09:31 PM |

|

|

If mounted 90-degrees from shown you would have trouble installing the bolt. The bolt would have to go into the chassis tube! The hole would

probably not weaken the tube much, but how would you put the nut on?

Another orientation would be to leave the bolt axis as it is shown, but rotate the bracket with it's 'back' against the tube. This

doesn't change the function of the bracket, but it lets you do an 'outside' weld around the bracket rather than trying to weld

around the inside curve. Is this stronger or weaker I don't know. Seems easier though.

HTH

-Andy

2000 Mustang GT

2003 Mustang Cobra 450RWHP/450RWTQ

2004 ZX-10R

In progress: 67 Mustang with 520ci(8.6L) V8, 600HP estimated

|

|

|

Avoneer

|

| posted on 4/8/05 at 09:50 PM |

|

|

Or I could just weld a bolt on like the Isonblade - that didn't break even after the crash!

Rescued attachment rearpanard.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 4/8/05 at 09:54 PM |

|

|

How about with the bracket welded at 90degrees (as per Fozzies said) and weld a nut to the inside of the bracket as well?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 4/8/05 at 10:02 PM |

|

|

Pat have you got Uncle Rons book (second edition)?...a lot of it is ...ahem...undesirable, but it will give you the idea on page 75 of how to position

it.

re the isonblade, the rose joint on that is positioned the right way round.

Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 4/8/05 at 10:12 PM |

|

|

Hi,

Yep, I have the book...I think that is the bracket on a "tapped" thick plate??? - The shock mount looks shocking though!

If I do it like this pic, and tap the brackets behind the nut as well (6mm of plates and and a small air gap between the inside of the bracket and the

axle tube) that will be a nice fim fixing won't it?

Pat....JPG)

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 4/8/05 at 10:20 PM |

|

|

Yup Pat ya got it

Yes some of the work shown in the book is a bit...ahem...shocking, I got the book coz I wanted to build a Locost....and race it...lol. I put it away

very quickly..lol. But, it does explain in the picture which way round the bracket and rod should go!

ATB Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 4/8/05 at 10:55 PM |

|

|

I knew you could use rose joints either orientation, but forgot how much the axle "may" move up and down, so not worth the risk and

it's not too hard to sort out this "new" way.

Just awaiting confirmation from Rorty and then I'll go forth and weld!

Thanks.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 4/8/05 at 11:00 PM |

|

|

Fozzie aka Foggie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 4/8/05 at 11:11 PM |

|

|

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 4/8/05 at 11:14 PM |

|

|

Pat, you cannot use rose joints in either orientation, they are not designed to work that way!!!!!!!!!!!!!!!!!!!!!!!

Fozzie

ps with rose joint in yer hand, bolt with head in vice sticking upwards, place rose joint over bolt, now try lifting rose joint up and down...will it?

NO. Now spin it round (like helicopter blade) and it will go around 360 degrees how many times ya like! Thats the way its designed to

work!!!!!!!!!!!!!!!!!

[Edited on 4/8/05 by Fozzie]

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

MikeRJ

|

| posted on 4/8/05 at 11:17 PM |

|

|

quote:

Originally posted by Avoneer

Hi,

Yep, I have the book...I think that is the bracket on a "tapped" thick plate??? - The shock mount looks shocking though!

If I do it like this pic, and tap the brackets behind the nut as well (6mm of plates and and a small air gap between the inside of the bracket and the

axle tube) that will be a nice fim fixing won't it?

Pat...

Errrm, not really. The outser edge of the bracket is unsupported and is doing nothing for the strength or rigidity of the mounting.

Looking at the first picture you posted, I would be tempted to turn the bracket 90 degrees clockwise (in the same axis as the panhard rod), weld one

edge of the bracket to the edge of the main axle bracket, and then weld a gusset at the back. Hard to explain, but like this:

In fact you could maybe also weld one edge to you shock bracket to make it even stringer.

[Edited on 4/8/05 by MikeRJ]

|

|

|

Fozzie

|

| posted on 4/8/05 at 11:23 PM |

|

|

Thanks Mike, you have managed to draw this as I had tried to describe in the second posting.

Pat was refering (in your quote) to the book (Ron Chapmans), showing the correct positioning of bracket and rose joint.

Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Rorty

|

| posted on 5/8/05 at 04:41 AM |

|

|

Sorry I'm late (as if you were really waiting for me, Pat  ). ).

I like the method illustrated in MikeRJ's sketch.

Rod ends can be made to operate at high angles 90 degrees to the bore's axis (I get 46 degrees out of them for steering), but it's much

simpler doing it the way that's been suggested.

Whilst I would never suggest the IsonBlade performs less than satisfactorily, mounting a rod end, on a lengthy spigot, on a thin-ish bit of sheet

metal, and in single shear, wouldn't be my way of guaranteeing a sound night's sleep.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Fozzie

|

| posted on 5/8/05 at 08:15 AM |

|

|

quote:

Originally posted by Fozzie

ooeer Pat,  , think about how axle moves in relation to panhard rod....you might want to turn it 90degs (bracket)... , think about how axle moves in relation to panhard rod....you might want to turn it 90degs (bracket)...

IMO you need to turn the bracket in your hand over 90 degrees, and put it next to the link bracket.

Fozzie

[Edited on 4/8/05 by Fozzie]

As said by me in the third reply on this thread.....

ta for ya confidence Pat... and cheers Mike for drawing what I said in the third post...memo to self......I must brush up on me computer drawing

skills! and cheers Mike for drawing what I said in the third post...memo to self......I must brush up on me computer drawing

skills!

Exactly Rorty ...the degrees of misalignment which is stated on the rose joint before ya buy......as stated on the fifth (?) post......

ATB Fozzie

[Edited on 5/8/05 by Fozzie]

[Edited on 5/8/05 by Fozzie]

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 5/8/05 at 11:23 AM |

|

|

Sorry foggie, takes a bit for me to come round to a better way of thinking!

So if I move my bracket in towards the centre of the car to gusset the back of it (like Mike's pic), I'll still have a problem with the

nut.

Can I still weld a nut to the inside of the bracket as per my latest pic and gusset the back?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

JB

|

| posted on 5/8/05 at 11:46 AM |

|

|

Panhard Rod SRE Orientation & Mounting

If it was my car I would actually use the first method suggested with the rod end horizontal. This gives the better load paths, is easier to make and

allows you to have a panhard rod as long as possible.

However you must check you do not run out of travel on the joint, ie it does not bind.

Mounting the SRE on a post in single shear ia a bad idea.

Mounting the SRE as in the last picture is a good idea, it is just more complicated to make.

Sperical bearings can operate in any orientation, in certain orientations you have less movement.

Check out most top racing cars that use spherical bearings (such as a Gould hillclimber, you will not find anything bad about this car) and the

sphericals are mounted horizontal at the chassis end.

John

|

|

|

Fozzie

|

| posted on 5/8/05 at 02:15 PM |

|

|

Hmmmm, well having been involved in preparing race cars for many years...and for Le Mans racing...I do have just a wee bit of experience in this....as

I have said before, you want to think of how the axle moves and how the rose joint moves, and then think of why you are putting it there. The

Isonblade as per picture (green springs) has the rose joint in the correct orientation. Yes it should be on a 'better' bracket, but I am

not going to criticize on that point, the isonblade is not the matter in question here.

Mikes drawing is spot on, the bracket has been made, you just have to turn it as described, and you will have to do a strengthening plate/gusset.

Uncle Rons book is not the best example of how to do things neatly, but the positioning is right.

Now I keep repeating myself.......I'll get me coat!..............................

Fozzie/Foggie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 5/8/05 at 03:32 PM |

|

|

I Heard you Foggie

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 5/8/05 at 03:47 PM |

|

|

Tee-hee-hee.....

Foggie ..aka Fozzie ..aka Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|