The Doc

|

| posted on 24/6/05 at 08:09 PM |

|

|

Suspension Bolts etc.

Hi folks,

Some basic questions about suspension bolts. Firstly are 8.8 high tensile enough? Should we be putting a washer under both bolt head and nut, just one

or the other - or does it matter at all! (nylocks assumed). Thirdly - is it ok for the bolt to pull up flush with the end of the nut, or does the SVA

man like to see a few threads protruding?

Cheers

Mike

|

|

|

|

|

shortie

|

| posted on 24/6/05 at 08:28 PM |

|

|

8.8 is fine, yes, washer both ends, nylocs and at least 2 threads showing

HTH,

Rich.

|

|

|

jambojeef

|

| posted on 24/6/05 at 09:06 PM |

|

|

Hi there,

I would ask what diameter of bolk shank you are planning to use and on what part of the suspension.

For example my front lower wishbone arms to chassis bolts are "only" M8 8.8 at the minute but the top are 1/2" UNF 8.8.

Having read posts on the subject I am of the opinoin that M8 8.8 at that part of the suspension only leaves a relatively small safety margin compared

to the rest of the suspension fasteners and so I plan to change these to 12.9 capheads before SVA.

I have used a washer both ends and nylocs as Shortie has.

Interesting to note that 2 threads should be showing Rich - is that an SVA requirement?

Geoff

|

|

|

shortie

|

| posted on 24/6/05 at 09:09 PM |

|

|

I know that there has to be sufficient showing for SVA, I belive from others that it is 2 threads at least but it is standard practice not just for

SVA.

HTH,

Rich.

|

|

|

smart51

|

| posted on 24/6/05 at 09:13 PM |

|

|

Does the 2 thread rule apply to nylocks only or do you have to do this with normal nuts as well?

|

|

|

Mark Allanson

|

| posted on 24/6/05 at 10:08 PM |

|

|

How does the nut know how many threads are showing?

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

Hellfire

|

| posted on 24/6/05 at 10:08 PM |

|

|

Just physical fasteners that use the end of the nut to lock ie castle/nylok/split/truncated etc etc

|

|

|

britishtrident

|

| posted on 25/6/05 at 07:53 AM |

|

|

A nyloc actually becomes a "self-slackening" nut if the nyon insert isn't fully on a parallel part of the thread

|

|

|

The Doc

|

| posted on 25/6/05 at 11:57 AM |

|

|

Thanks for that folks,

I've gone the standard 'book' suspension bush route where the bolts are more like M9 but are actually UNF. Anything else is sloppy

or wont go in.

I have now taken all the F****n wishbone bolts out and put slightly longer bolts in. What a pain the the arse, but better now than after completion I

keep telling myself!

PS Anyone know where I can get hold of one of those 90 degree speedo cable outputs for the crossflow gearbox

|

|

|

Jeffers_S13

|

| posted on 27/6/05 at 10:52 AM |

|

|

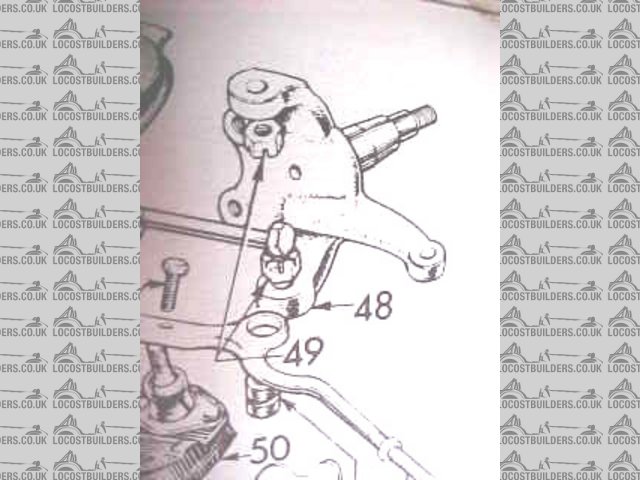

I noticed the top front wishbone ball joint thread isnt long enough on my car, the thread *just* gets flush with the end of the castle nut under the

top part of the upright, can you get ball joints with a longer threaded section ??? see pic in archive for better description of what I mean...

[Edited on 27/6/05 by Jeffers_S13]

|

|

|

MikeRJ

|

| posted on 27/6/05 at 11:55 AM |

|

|

quote:

Originally posted by Jeffers_S13

I noticed the top front wishbone ball joint thread isnt long enough on my car, the thread *just* gets flush with the end of the castle nut under the

top part of the upright, can you get ball joints with a longer threaded section ??? see pic in archive for better description of what I mean...

[Edited on 27/6/05 by Jeffers_S13]

Same problem on mine. I think the standard fix is to have the taper in the upright reamed out a bit more.

|

|

|

Jeffers_S13

|

| posted on 27/6/05 at 12:03 PM |

|

|

Surely not ? thats gonna be a right chew on at this stage of my build. I only just noticed it as I was fitting the calipers.

|

|

|

Rorty

|

| posted on 28/6/05 at 05:51 AM |

|

|

quote:

Originally posted by jambojeef

...my front lower wishbone arms to chassis bolts are "only" M8 8.8 at the minute but the top are 1/2" UNF 8.8.

Having read posts on the subject I am of the opinoin that M8 8.8 at that part of the suspension only leaves a relatively small safety margin compared

to the rest of the suspension fasteners and so I plan to change these to 12.9 capheads before SVA.

There is no such thing as a "1/2" UNF 8.8" fastener. You're confusing two entirely different and non-interchangeable thread

systems.

Class 8.8 fasteners are indeed metric, but your "1/2" fasteners are imperial and graded, not classed. The nearest imperial equivalent of a

Class 8.8 bolt would be a Grade 5 item.

At 150 PSI, a SAE Grade 8 is almost equivalent to the metric Class 10.9 (1034 MPa) and a Class 12.9 fastener comes in at 1200MPa.

So, if you are actually planning on using Class 12.9 bolts for the wishbones, then I assume they'll be M6 (6mm diameter)?

As most of the wishbone fittings will be designed for imperial fasteners, then 1/2" Grade 8 fasteners will be more than man enough for the job.

If you were pinching weight for racing, then you could even step down a size to 3/8" Grade 8 bolts, though you'd obviously have to make

new cruch tubes for the wishbone bushes.

As a rule, a washer is not necessary under the head of a bolt, unless the fillet between the head and shank of the bolt will interfere with the

edges of the hole. I usually just countersink the edges of the holes where there is insufficient clearance, though in reality, if you follow the

standards for bolt/hole tolerances, then you'll not have to worry about it. If you are required to fit a washer, make sure it too either has

clearance for the fillet or is countersunk/radiused. I only use militry ground, hardened and radiused washers.

A washer should be fitted under all nuts, no matter what their style or material. For anything mechanical or critical, purchase, as a minimum,

hardened washers. The plain mild steel ones that you can buy at every hardware shop are just OK for resillient components, but are too soft for

bolting against aluminium. If using the stamped variety of washer, place the top (rounded) side against whatever is being bolted and not the nut.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

David Jenkins

|

| posted on 28/6/05 at 07:10 AM |

|

|

Just remember folks, when getting technical about suspension bolt types and strengths, that the bolt is held by a strip of mild steel just 3mm or

1/8" thick.

I would suspect that the suspension brackets would give way a long time before the bolt even got bent.

Just my 2p's worth...

David

|

|

|

The Doc

|

| posted on 28/6/05 at 07:31 AM |

|

|

Ball Joint Threads

Jeffers,

I see that you have washers (quite thick ones at that) under your ball joint nuts. The Cortina manual shows no washers. Drop these and you might get

the clearance you're after. (pic attached)

Rescued attachment MVC-001E.JPG

|

|

|

Jeffers_S13

|

| posted on 28/6/05 at 09:43 AM |

|

|

Aha ! good spot ! will try this

Thanks

James

|

|

|

jambojeef

|

| posted on 29/6/05 at 09:09 AM |

|

|

Hi Rorty,

Thanks for keeping me right there buddy - I meant "equivalent 8.8 1/2" UNF"

I think its grade R IIRC

cheers

Geoff

|

|

|