James

|

| posted on 22/2/12 at 04:48 PM |

|

|

Wishbone jigs- any neat ideas?

The more time I spend poking round my car the more unhappy I am with the front wishbones.

I was pretty naive when I made them and I made a quick 'get me through SVA, sort it later' bodge to the upper ones that's never got

fixed. Now I see it, and having seen a few disasters on here, I wonder I'm still alive!

So I want to re-make both top and bottom ones but I'm wondering what people have done for jigs. Anything cunning/really neat?

I've got the Roadster book as well as the Champion 2nd edition so have seen what they suggest. I was thinking of using 18mm MDF for the base,

re-inforced with angle iron on the bottom/sides and screw/bolt brackets to the top of this to hold the metal pieces.

Just want accuracy and symetrical wishbones (where applicable  ). Who's done something better than the above? Any pics etc.? ). Who's done something better than the above? Any pics etc.?

Thanks!

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

|

|

liam.mccaffrey

|

| posted on 22/2/12 at 05:43 PM |

|

|

I've done a few sets now all custom, I have a heavy gauge steel sheet about 4mm I think, which I tack bits of left over chassis box in the

correct places to locate the tubes.

Easy and quick, I was very happy with both the symmetry and accuracy.

top bone

[Edited on 22/2/12 by liam.mccaffrey]

Build Blog

Build Photo Album

|

|

|

Neville Jones

|

| posted on 22/2/12 at 05:51 PM |

|

|

James,

To get repeatability and accuracy, you need to use steel to make your wishbone jigs. The heaviest you can lay your hands on.

I'll bet those racecar people you worked for(still do?) don't use mdf to make their wishbone jigs.

MDF changes with temp and humidity.

Cheers,

Nev.

|

|

|

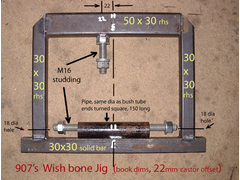

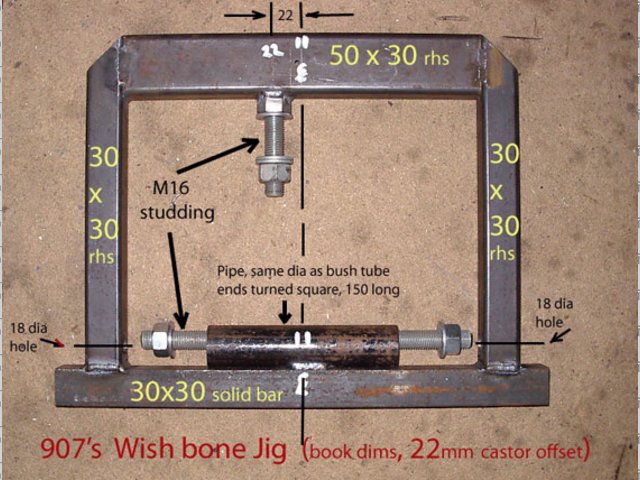

907

|

| posted on 22/2/12 at 05:53 PM |

|

|

IMHO

A good jig should allow the part to be fully welded while still held in the jig.

Paul G

Front top wish bone jig

|

|

|

Slimy38

|

| posted on 22/2/12 at 06:53 PM |

|

|

quote:

Originally posted by Neville Jones

James,

To get repeatability and accuracy, you need to use steel to make your wishbone jigs. The heaviest you can lay your hands on.

I'll bet those racecar people you worked for(still do?) don't use mdf to make their wishbone jigs.

MDF changes with temp and humidity.

Cheers,

Nev.

I agree for repeatability and accuracy then a good heavy metal jig would be best, but surely if you're only making a pair it doesn't have

to last that long? Even the worst welder in the world (IE me!) could complete a couple of wishbones in an hour or so? That's not much time for

wood to swell or warp.

I wouldn't use MDF though, I'd consider plywood to be a better medium.

|

|

|

phelpsa

|

| posted on 22/2/12 at 09:13 PM |

|

|

quote:

Originally posted by Neville Jones

James,

To get repeatability and accuracy, you need to use steel to make your wishbone jigs. The heaviest you can lay your hands on.

I'll bet those racecar people you worked for(still do?) don't use mdf to make their wishbone jigs.

MDF changes with temp and humidity.

Cheers,

Nev.

I put money on them using low grade ali plate for fabrication jigs, although if we're thinking of the same company, they probably don't

make fabricated wishbones very often

inch MDF with steel bracketry is fine for one offs.

[Edited on 22-2-12 by phelpsa]

|

|

|

scutter

|

| posted on 22/2/12 at 10:16 PM |

|

|

James, for my uppers I got a piece of 8mm plate bent up. My bones use rose joints at the inner points.

Jig1

ATB Dan.

The less I worked, the more i liked it.

|

|

|

James

|

| posted on 23/2/12 at 04:14 PM |

|

|

Okay, thanks all. Any more pics?

I think there's a piece of ~10mm steel kicking around somewhere, should it be thicker than this?

I assumed that MDF was relatively stable to temp etc.- I guess not!

quote:

Originally posted by phelpsa

quote:

Originally posted by Neville Jones

James,

To get repeatability and accuracy, you need to use steel to make your wishbone jigs. The heaviest you can lay your hands on.

I'll bet those racecar people you worked for(still do?) don't use mdf to make their wishbone jigs.

MDF changes with temp and humidity.

Cheers,

Nev.

I put money on them using low grade ali plate for fabrication jigs, although if we're thinking of the same company, they probably don't

make fabricated wishbones very often

inch MDF with steel bracketry is fine for one offs.

[Edited on 22-2-12 by phelpsa]

Sadly Neville, my job there was outsourced for 2007 onwards- a great shame!  Turned out Ricardo's machines were a bit more accurate than me

with a grinder! Who knew! Turned out Ricardo's machines were a bit more accurate than me

with a grinder! Who knew!

I have no idea what is used for carbon wishbones, never got to see that- am sure you know better than me!

Any other suggestions... keep 'em coming!  They need to be of the available to the unemployed/poor with only tiny garage type facilities type

of person! They need to be of the available to the unemployed/poor with only tiny garage type facilities type

of person!

Thanks!

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|