motobaleno

|

| posted on 28/10/10 at 11:27 AM |

|

|

diff problems

Hello

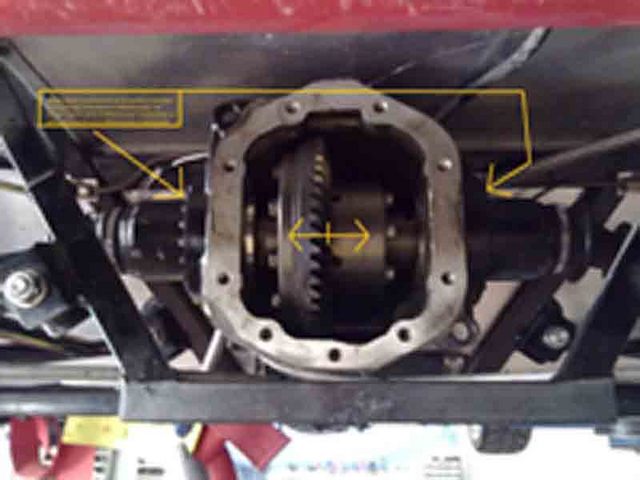

I have upgraded my Raw striker from a standard sierra diff to a Quaife unit. Now I hear a loud noise coming from the diff when opening gas in a

corner.

In my opinion (but I could be wrong) this noise does not come from the normal action of the lsd...

Can you give some hints to solve the problem? (IF IT IS a problem)

In particular, I wonder about the tightening torque of the registers highlighted in the picture...

Can you tell me the right value of this tightening torque? or alternatively, given the problem that I suffer, can you tell me if it should be better

to loose these registers or it should be better to tighten them?

Or maybe it could be an offset problem? (if I loose one register and tighten the other one the diff obviously moves laterally...)

sorry for my english (I'm from Italy...)

|

|

|

|

|

motobaleno

|

| posted on 28/10/10 at 11:30 AM |

|

|

of course the photo didn't upload...

trying to fix...

any way you can find the photo in my photo album (motobaleno) it is the only one...

|

|

|

loggyboy

|

| posted on 28/10/10 at 11:32 AM |

|

|

Description

|

|

|

motobaleno

|

| posted on 28/10/10 at 11:38 AM |

|

|

THANKS!

|

|

|

coozer

|

| posted on 28/10/10 at 11:43 AM |

|

|

Re the registers, are they in the correct position to give the required crown wheel to pinion backlash?

1972 V8 Jago

1980 Z750

|

|

|

mcerd1

|

| posted on 28/10/10 at 12:08 PM |

|

|

Diff Manual Linky p1

Diff Manual Linky p2

Diff Manual Linky p3

Diff Manual Linky p4

Diff Manual Linky p5

Diff Manual Linky p6

Diff Manual Linky p7

Diff Manual Linky p8

Diff Manual Linky p9

Diff Manual Linky p10

Diff Manual Linky p11

Diff Manual Linky p12

Diff Manual Linky p13

Diff Manual Linky p14

Diff Manual Linky p15

Diff Manual Linky p16

-

|

|

|

CNHSS1

|

| posted on 28/10/10 at 12:28 PM |

|

|

quaife is silent in operation, no noise should be present at all. Could be pinion/CW mesh or a bearing breaking up. Dont run it though until sorted

"Racing is life, everything else, before or after, is just waiting"---Steve McQueen

|

|

|

blakep82

|

| posted on 28/10/10 at 12:32 PM |

|

|

what sort of noise?

i have a LSD in my BMW (standard fit) which as far as i know is a plate type LSD, it used to make a growling rumbling noise when i went round corners,

but a change of oil sorted it.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

motobaleno

|

| posted on 28/10/10 at 12:53 PM |

|

|

quote:

Originally posted by coozer

Re the registers, are they in the correct position to give the required crown wheel to pinion backlash?

Is there any simple way to determine the correct position to give the required backlash?

[Edited on 28/10/10 by motobaleno]

|

|

|

CNHSS1

|

| posted on 28/10/10 at 01:17 PM |

|

|

quaife isnt plated or viscous LSD, its an ATB 'torsen' geared type, no plates

"Racing is life, everything else, before or after, is just waiting"---Steve McQueen

|

|

|

arrow-engineering

|

| posted on 28/10/10 at 01:19 PM |

|

|

diff

the only way to tell if the teeth are meshing correctly is to coat all the teeth on the crown wheel with engineers blue, then turn the input shaft in

the direction of drive(normally clockwise looking from the front) and apply load to the crown wheel to simulate driving. the pattern that is left in

the blue will give a good indication of how the teeth are touching each other, you should have a smooth pattern that sits right in the middle of the

teeth. to measure the backlash you will need a magnetic base and a dti with the plunger set at right angle to the top of a tooth, rock the crown wheel

back and forth and take the reading. too big a reading means you need to move the assembly nearer the pinion, too small you need to move the assembly

away from the pinion - but you must retain the bearing preload at all times.

|

|

|