markie t

|

posted on 10/10/10 at 09:36 PM posted on 10/10/10 at 09:36 PM |

|

|

help needed, propshaft come off

was out tonight and on the way home my propshaft decided to detatch itself from the gearbox (99 r1) and ended up coming home on a recovery truck. As a

result of flailing around it has damaged the threads slightly on the shaft that the adaptor sprocket goes onto, can somebody please let me know if

this is a main shaft for the gearbox and would the threads be ok to be tapped and die'd and re bolted back together, thanks, mark.

|

|

|

|

|

eznfrank

|

| posted on 10/10/10 at 09:39 PM |

|

|

Did you have a prop catcher?? Sounds like you got off VERY lightly if that's all it did!!

|

|

|

markie t

|

| posted on 10/10/10 at 09:48 PM |

|

|

yes i think so, there is a large rubber mount that holds the propshaft central just inside the front of the tunnel, it is only front end of the prop

that has been spinning/flailing in the engine bay, i sh*t myself when it happened, sounded horrible!!!

|

|

|

snapper

|

| posted on 11/10/10 at 05:20 AM |

|

|

When you find a solution and effect a repair, use thread lock on every nut and bolt, also consider wire locking critical componants.

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

mangogrooveworkshop

|

| posted on 11/10/10 at 07:50 AM |

|

|

Might help putting your location in to see if theres other builders in your area who could help you out

<<<<<<<<<<<< poulton nr blackpool.

A prop catcher may be needed and a very good check of all the components in the drive train.

a person that would help you is AB engineering Andy Bates. he is a specialist in the bec field.

|

|

|

Breaker

|

| posted on 11/10/10 at 09:29 AM |

|

|

On many pictures of BEC-chassis I've seen(Including Indy R that I have) the output flange of the gearbox is not parallel to the diff flange.

This will cause vibration and stress to the gearbox/diff/flanges.

I will certainly reposition the bike engine in my chassis so it is perfectly in line with the diff.

More reading here :

UJ - linky

|

|

|

boggle

|

| posted on 11/10/10 at 11:29 AM |

|

|

i cannot get my blade engine parralell to my diff....it just wont fit

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

ReMan

|

| posted on 11/10/10 at 01:04 PM |

|

|

quote:

Originally posted by Breaker

On many pictures of BEC-chassis I've seen(Including Indy R that I have) the output flange of the gearbox is not parallel to the diff flange.

This will cause vibration and stress to the gearbox/diff/flanges.

I will certainly reposition the bike engine in my chassis so it is perfectly in line with the diff.

More reading here :

UJ - linky

It does not need to be perpectly in line, that's why you have a UJ's

But the faces should be roughly parrallel

|

|

|

ReMan

|

| posted on 11/10/10 at 01:09 PM |

|

|

quote:

Originally posted by mangogrooveworkshop

Might help putting your location in to see if theres other builders in your area who could help you out

<<<<<<<<<<<< poulton nr blackpool.

A prop catcher may be needed and a very good check of all the components in the drive train.

a person that would help you is AB engineering Andy Bates. he is a specialist in the bec field.

Not tempting fate, but surely a prop catcher is after the event?

Prevention beteer than cure an all that

However I agree that it would be very easy at to build in a load more ribs of box/tube section in the tunnel top and sides, which would easily contain

it should the worst happen

|

|

|

Breaker

|

| posted on 11/10/10 at 01:09 PM |

|

|

quote:

Originally posted by ReMan

It does not need to be perpectly in line, that's why you have a UJ's

But the faces should be roughly parrallel

Indeed, that was what I meant.

|

|

|

Liam

|

| posted on 11/10/10 at 08:13 PM |

|

|

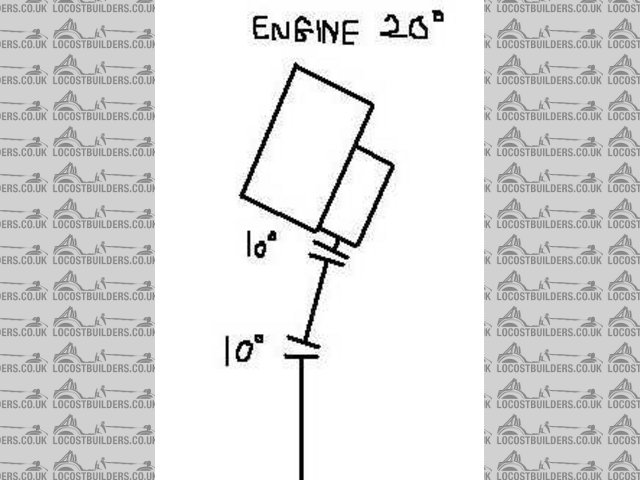

You dont have to have the input and output planes parallel to be able to cancel out the non-uniform velocity. You just need two joints with the same

angle on them - e.g. in the BEC application have the same angle on the sprocket adaptor joint and the centre joint.

Or just stick a rubber cush drive in there!

|

|

|

Breaker

|

| posted on 12/10/10 at 08:12 AM |

|

|

quote:

Originally posted by Liam

You dont have to have the input and output planes parallel to be able to cancel out the non-uniform velocity. You just need two joints with the same

angle on them - e.g. in the BEC application have the same angle on the sprocket adaptor joint and the centre joint.

I don't quite understand what you're saying. Can you post a small drawing ?

|

|

|

sickbag

|

| posted on 12/10/10 at 08:20 AM |

|

|

Given the short-comings of UJ's would it not be better to have the propshaft made up with CV joints instead? Can they be requested when having

one made up?

I only ask as I'll be needing one soon and don't like the idea of a UJ failing.

Finally back on the job!

|

|

|

Liam

|

| posted on 12/10/10 at 12:46 PM |

|

|

quote:

Originally posted by Breaker

quote:

Originally posted by Liam

You dont have to have the input and output planes parallel to be able to cancel out the non-uniform velocity. You just need two joints with the same

angle on them - e.g. in the BEC application have the same angle on the sprocket adaptor joint and the centre joint.

I don't quite understand what you're saying. Can you post a small drawing ?

Eg like this...

Description

First joint cancels the second joint. Same principle as those double joints used in offroading when the propshafts are hanging down for big ground

clearance.

|

|

|