James

|

| posted on 31/10/05 at 03:17 PM |

|

|

quote:

Originally posted by NS Dev

I know the cortina upright wasn't designed for our application but it was a lot closer than the bottom of a McPherson leg!

I've been interested for ages in the suspension geometry/handling issues relating to changing wishbone lengths.

Assuming most people are using a Sierra rear axle then either you have a much narrower front than rear (4 or 5" ) or you increase the length of

the front wishbones to match.

But what are the geometry implications of the longer wishbones but used with a Cortina upright? Clearly the likes of MK have lengthened their front

w/bones but that's with a Sierra upright.

Any idea what happens if you mix the two designs? Ie. Sierra track w/bones but with Cortina uprights!

Cheers,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

|

|

flak monkey

|

| posted on 31/10/05 at 03:24 PM |

|

|

quote:

Originally posted by James

I've been interested for ages in the suspension geometry/handling issues relating to changing wishbone lengths.

But what are the geometry implications of the longer wishbones but used with a Cortina upright? Clearly the likes of MK have lengthened their front

w/bones but that's with a Sierra upright.

Any idea what happens if you mix the two designs? Ie. Sierra track w/bones but with Cortina uprights!

Cheers,

James

I would hope that in theory not much changes. However the amount of camber change in bump will change because the wishbones are longer for any given

bump the amount of camber change will be smaller. (I think).

I am using longer wishbones with cortina uprights, and hopefully the implications are pretty small.

David

Sera

http://www.motosera.com

|

|

|

JoelP

|

| posted on 31/10/05 at 03:52 PM |

|

|

id be suprised if ron calculated it that accurately in the beginning anyway

|

|

|

marc n

|

| posted on 31/10/05 at 03:53 PM |

|

|

hi rorty

got the files they are now at the laser cutters / machine shop should know in a couple of days the prices etc ,

have already had the stubs made to suit cortina so ok on that front

will keep you all up to date on the progress

best regards

marc

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

flak monkey

|

| posted on 31/10/05 at 10:00 PM |

|

|

The geometry of the sierra upright is different AFAIK, hence why the top wishbone in sierra fronted cars are different. The offset is different for a

start.

The cortina upright came off a car with double front wishbones, the sierra did not. hence the cortina was better designed for our purposes surely. If

the sierra is OK its only luck.

David

Sera

http://www.motosera.com

|

|

|

Rorty

|

| posted on 31/10/05 at 10:03 PM |

|

|

quote:

Originally posted by James

quote:

Originally posted by flak monkey

quote:

Originally posted by fatfranky

Rorty, Marc etc.

Forgive my ignorance but what is wrong with Sierra uprights?

I appreciate that they are basically the bottom part of a MacPerson strut adapted to accept an upper ball joint but what is wrong with this

arrangement?

And why are Cortina uprights so superior?

As Liam said, plus the geometry is also better suited to a double wishbone set up.

David

Clearly I know next to bugger-all about suspension design etc. but I had a long chat with Darren (GTS) and Peter from Raceline about the benefits of

each and I was pretty sure that they felt that apart from the weight the Sierra was a better design in terms of geometry.

Amongst others the things I remember were the scrub radius was better with the Sierra and the position of the wheel relative to the bearings meant

less strain on the wheel bearings.

Either way, it'd be good to get an accurate/comprehensive set of measurements of the Sierra upright to Rorty so he could do a Sierra version!

Cheers,

James

James, I realise you're only passing on what you heard, but in my mind, the collective thinking is flawed.

For a start, the Sierra upright's geometry should be exactly the same as the Cortina's, as that's what it's supposed to be

emulating so it fits the Book wishbones! A bit more KPI would benefit it, though I'm not sure that's possible with the Sierra unit.

I can't comment on the difference in scrub radius between the uprights, as I've never measured a Sierra upright, however, the scrub radius

of either upright can be corrected/altered by swapping wheels with different offsets.

Again, I have no experience of the Sierra upright, but in a car the weight of a Locost, the stress on wheel bearings is moot.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Rorty

|

| posted on 31/10/05 at 10:10 PM |

|

|

quote:

Originally posted by flak monkey

The geometry of the sierra upright is different AFAIK, hence why the top wishbone in sierra fronted cars are different. The offset is different for a

start.

David

Aha! OK, I thought the Sierra upright was designed as a direct replacement for the Cortina one and for the standard Book wishbones.

If that's the case, then, presumably, with the mushroom, the KPI has been increased. Does anyone know if that's the case?

Seems rather pointless if it hasn't.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

JoelP

|

| posted on 31/10/05 at 10:57 PM |

|

|

with the offcentre mushrooms, you could increase KPI, but its often traded off as people change (or attempt to change!) castor.

Is more KPI desirable?

[Edited on 31/10/05 by JoelP]

|

|

|

Syd Bridge

|

| posted on 1/11/05 at 09:12 AM |

|

|

The Sierra kpi is 13-13.5 degrees, due solely to the McPherson strut design and clearance issues.

The Cortina is similar to the Mk1&2 Granadas, at around 8+/-degrees, which is common with most suspensions of this type. eg. early Holdens,

Falcons, USA Fords and Chevy's, ........

The front of a 911 is a real dogs dinner, with large amounts of kpi for the strut to clear in a small(ish) space, then large amounts of castor to

offset that, and make the ultralight frontend steer.

I'm not sure what the uprights in the early 6's, then 7's were, but from the drawings I have there is minimal scrub, and low KPI and

castor. Caterham and Lotus then went on to use the Triumph upright (or their own versions of it), which have similar geometry to the early

examples.

Work it out for yourselves, I can't give a definitive answer. But, if you tried to use some of the geometries seen in 7 type cars, in much

heavier cars, you'd have all sorts of handling problems. The Cortina hub/uprights is a good example. The wheel mount faces were outside of the

rim edge, much like Austin 1100/1300's, just to keep some semblance of centrepoint steering. You then put low offset wheels on, and centre

offset goes wildly high with steering kickback. But, the light car seems to forgive it, or at least not emphasize it.

Seems as though the very light weight forgives a multitude of design sins, which you would not find on a competently designed top end racecar.

Syd.

[Edited on 1/11/05 by Syd Bridge]

|

|

|

James

|

| posted on 1/11/05 at 10:08 AM |

|

|

quote:

Originally posted by Rorty

For a start, the Sierra upright's geometry should be exactly the same as the Cortina's, as that's what it's supposed to be

emulating so it fits the Book wishbones! A bit more KPI would benefit it, though I'm not sure that's possible with the Sierra unit.

Actually, very few people I know of use the Sierra upright with The Book wishbones.

Firstly, the Sierra upper BJ hole is in a different (relative to the lower BJ) position. Meaning even with the top BJ wound right in you still

can't fit it so therefore you need a shorter top wishbone anyway.

Secondly, if you're using Sierra donor uprights at the front you're probably using a Sierra donor back end. This is 4" or 5"

wider than the front (Book!) track.

Do you really want that sort of front/rear track difference? I know Ned is using it like this but I've no idea on the effect on handling

characteristics doing this. Ok, it works for Go-Karts but does that really translate?!

It'd be a weird track anyway as the hub plate is off-set differently Sierra/Cortina so the track would be a slight variation anyway.

I don't know of any manufacturers using a mixed track (narrow front, wide backend) like this. MK, Luego, GTS et al use Sierra back end with

longer (than book) front wishbones so front/rear track matches.

What I conclude from this is that I need to spend more time reading my "Chassis Adjustment Analysis" suspension design book lent to me by

a mate who works for McLaren!

Cheers,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

drmike54

|

| posted on 1/11/05 at 11:52 PM |

|

|

I am drooling over Rorty's upright design. It is such a pain that cars with suitable uprights are pretty much gone.

Started Welding the chassis!!!!

|

|

|

jcduroc

|

| posted on 2/11/05 at 01:00 AM |

|

|

quote:

Originally posted by NS Dev

surely the scrub radius will depend on what offset wheels are used! You can't say one is better than the other without including the full

package.

First of all let me salute our friend Rorty for his coming back, cheerful and operative as ever. Cheers, Bob.

As for scrub radius the fact is that FOR EQUAL WHEEL+TYRE it depends on the upright+hub+disc arrangement.

For an ET38 wheel the Cortina components give a scub radius of 82.9 mm.

The same wheel with Sierra components (based on the data I got from the Web) give a scrub radius of 33.2 mm.

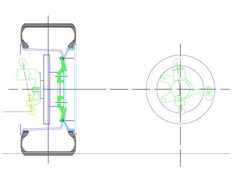

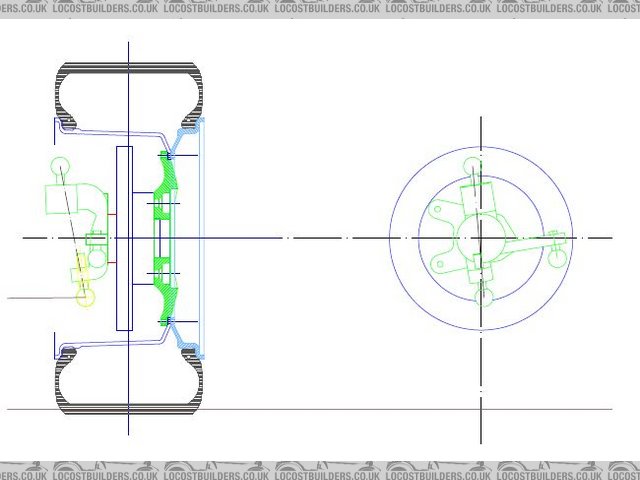

Rescued attachment Uprt-Sierra-1.jpg

JCM

|

|

|

jcduroc

|

| posted on 2/11/05 at 01:01 AM |

|

|

Cortina

Rescued attachment Uprt-Cortina-ScrubRadius.jpg

JCM

|

|

|

Rorty

|

| posted on 2/11/05 at 07:50 AM |

|

|

My figures are virtually identical to your findings Joao.

I suppose the next logical step I may look at would be to come up with not just a Cortina replacement upright, but a purpose designed light weight

Locost upright and matching wishbones.

Would Marc, Mark (I sound like a dog with a hair lip) Brad or Chris be interested in such a set-up?

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Syd Bridge

|

| posted on 2/11/05 at 01:01 PM |

|

|

Cast ali uprights to fit front Sierra bearings and stubs, with Cortina balljoint geometry, are already available.

I saw them at STATUS quite a few years ago. They may have been for a manufacturer though.

Ring Manchester Uni and ask for STATUS and someone could sort you all out.

I drew some for the IP Sprite project in '96, and made a pattern for the castings, if I can ever find them in the shed. The geometry is for

13" wheels, custom discs and AP brakes, but needs little changing for Locosts. Looks like the time for a batch looks nigh.

Syd.

|

|

|

jcduroc

|

| posted on 2/11/05 at 04:45 PM |

|

|

Ernesto Freitas (lusomotors.com) designed an upright + hubs to replace either the Cortina or Sierra ones.Image deleted by owner

JCM

|

|

|

BradW

|

| posted on 6/11/05 at 09:24 PM |

|

|

Hi,

Been away from the forum for a few days, thanks Rorty for the files, in answer to your question "Would Marc, Mark (I sound like a dog with

a hair lip) Brad or Chris be interested in such a set-up? ", yes, I think that might be an idea, I've thought a few times about something

like that.

A few "requirements" I'd thought of would be

1) Cater for 'standard' book wishbones

2) Use book Transit & Maxi/Cortina ball joints

3) Use Sierra hubs and bearings

4) Removable/replaceable Caliper mounting plate

5) KPI of 7 or 8 degrees

6) Relatively easy to manufacture, using laser cutting/milling/turning/welding type of facilities rather than bending/forming.

I'm sure guys can add more to this list, maybe on here we can come up with a 'Locost' uprights and get away from being tied to

Cortina, Sierra or expensive ali uprights.

Cheers

Brad

|

|

|

Rorty

|

| posted on 7/11/05 at 05:34 AM |

|

|

All your points are noted; however I would question the logic of making any further uprights to fit Book wishbones.

The uprights I posted above were simply intended as a substitute for the diminishing Cortina uprights.

If I were to design an easily made (read composite) upright specifically for the Locost, I think it would be taking a step backwards to base it around

the Book 'bones with their inherent problems.

I feel if people are prepared to make uprights, then they're probably already prepared to make wishbones.

If there's enough interest in a full front end design, then I'm happy to knock one out. I have my outlaws coming to stay for Christmas

AGAIN this year, so that would be an ideal opportunity for me to sneak away for a bit of peace and quiet.

I would like to see a bit more input from others who would be genuinely interested in such a set-up, firstly, so I can establish if it's even

worth my while bothering and secondly, to ascertain what others think about Sierra hubs/bearings and which callipers to use etc.

Interchangeable calliper brackets could quite simply be retained by a bolt-in stub axle and located by keys on the opposite side of the upright.

Anyway, let's hear some dialogue first.

If it's not too presumptuous, I'll start a fresh thread "New Locost front end design."

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

cymtriks

|

| posted on 7/11/05 at 08:06 PM |

|

|

upright questions

Just a few questions:-

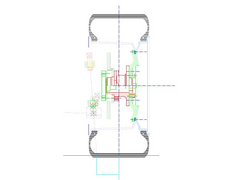

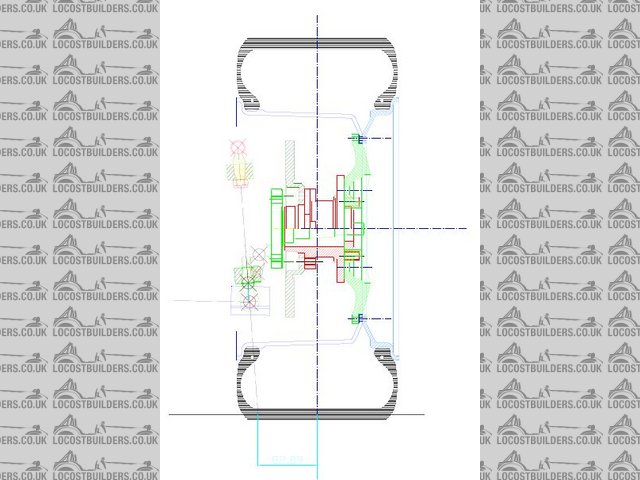

What size of RHS is the RHS upright made out of?

What thickness of steel is the laser cut and folded upright made of?

How are axles fitted into mass produced uprights? Can we copy this method as opposed to welding them in place?

Sorry to bombard you like this and I appreciate that some of the answers might be trade secrets like the CAD files but these will be essential to

anyone trying to make your designs or help them make their own design.

|

|

|

Rorty

|

| posted on 7/11/05 at 09:06 PM |

|

|

quote:

Originally posted by cymtriks

Just a few questions:-

What size of RHS is the RHS upright made out of?

What thickness of steel is the laser cut and folded upright made of?

How are axles fitted into mass produced uprights? Can we copy this method as opposed to welding them in place?

Sorry to bombard you like this and I appreciate that some of the answers might be trade secrets like the CAD files but these will be essential to

anyone trying to make your designs or help them make their own design.

Not a secret at all. RHS for these uprights is 50 x 50 x 3 [2 x 2 x .120].

The thickness of the main plate is 8mm and the braces are 6mm thick.

The stub axles of most commercial uprights are integrally cast. Some are welded and some have a male thread on their spigot and are retained by a nut

and some have a female thread and are retained by a single (usually 12 mm [1/2"]) bolt.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Alan B

|

| posted on 7/11/05 at 09:08 PM |

|

|

quote:

Originally posted by cymtriks

....How are axles fitted into mass produced uprights? .....

I believe that often they aren't as such because they are machined in one piece from a blank forging.

(awaiting correction... ) )

Damn, Rorty beat me to it...LOL

[Edited on 7/11/05 by Alan B]

|

|

|

marc n

|

| posted on 17/11/05 at 08:40 AM |

|

|

first lot of pricing has been done on the components for the uprights, they are looking like they will be £110 per pair powder coated, this includes

bolt on stub axles and various options on fittings ( i.e maxi balljoints, transit draglinks , rod end and pin assemblies, as we do ours at the moment

)

awaiting final prices on machined components ( may be cheaper yet ) and also on alloy hubs to go with these

please let me know your thoughts,

i will be producing these for ourselves and would be more than happy to supply the components for self assembly also for all you hardcore locosters

price for the alloy hubs is going to be £75 per pair inc bearings and nuts etc

best regards

marc

[Edited on 17/11/05 by marc n]

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

BKLOCO

|

| posted on 17/11/05 at 09:11 AM |

|

|

Rorty.

Am I correct in my thinking that ADR's (Australian Design Rules) do NOT allow the use of composite/RHS/welded construction uprights?

I'm intending eventually to export my car from UK into Queensland so this is of concern to me.

Experience is what you get when you don't get what you want!!!

|

|

|

Rorty

|

| posted on 17/11/05 at 12:01 PM |

|

|

The ADRs are an abomination. They vary from state to state and are difficult to keep abreast of. You can get almost anything through if you find a

friendly acredited engineer. It would be dificult to get some half-arsed uprights through if they were all rusty and the welds looked like chicken

poo, but if they appear to be professionally made, or even better, if you can present an invoice from the manufacturer, then I don't think

you'd have any problems.

I'm not an authority on ADRs though, so I would contact a car club in the state of your intended destination and ask them who the best engineer

is to speak to and what local regulations apply.

Perhaps the Aus Locost site could shed some light on it all for you.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

BKLOCO

|

| posted on 17/11/05 at 09:26 PM |

|

|

Thanks Rorty.

I've been chatting to Syd Bridge who seems to know quite a lot about importing into Queensland.

Seems it may not be a problem as long as it's a "personal Import" as my own car and that I have owned it for a minimum of a year.

It then only has to comply with the Queensland Code of Practice for Light Vehicles:

Seat Belt Mounting ADR5/00

Seat Belts Adr4/00

Child Restraint Anchorages ADR3/00 5/00 (in a 7?)

Safety Glass ADR 8/00

Head Restraints ADR22/00

Experience is what you get when you don't get what you want!!!

|

|

|