Rorty

|

| posted on 2/10/05 at 11:51 PM |

|

|

quote:

Originally posted by gazza285

quote:

Originally posted by Rorty

I doubt if you would find any bolt-on stub axles

Could you not use the VAG ones that youmentioned the other day?

Yeah, could do, though they'd require a comensurate plate welded to the upright first because of the broad based PCD on them.

The bolt-on type of stub axle that would work the easiest would be one with a threaded spigot which would bolt through the upright.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

|

|

gazza285

|

| posted on 3/10/05 at 12:05 AM |

|

|

I know, just thinking about cost and availability.

Raceleda do a Cortina sized stub axle, but they won't tell you the price on the website.

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

Rorty

|

| posted on 3/10/05 at 12:21 AM |

|

|

quote:

Originally posted by gazza285

... they won't tell you the price on the website.

That usually means you'd be able to make them cheaper yourself.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

gazza285

|

| posted on 3/10/05 at 12:24 AM |

|

|

Its been a while since I've used a lathe in anger though, have to dig out the micrometers.......

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

iank

|

| posted on 3/10/05 at 07:23 PM |

|

|

quote:

Originally posted by Rorty

quote:

Originally posted by gazza285

... they won't tell you the price on the website.

That usually means you'd be able to make them cheaper yourself.

MNR sell them for £379 inc VAT

http://www.mnrltd.co.uk/Suspension%20Components.html

|

|

|

gazza285

|

| posted on 3/10/05 at 09:36 PM |

|

|

We want the price of the stub axle, not the complete upright kit.

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

Rorty

|

| posted on 4/10/05 at 05:29 AM |

|

|

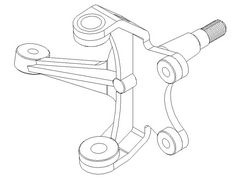

Cortina upright weight comparisons.

Out of sheer curiosity I just compared the mass of the various Cortina uprights.

The standard cast steel upright as found on the Cortina car weighs in at 2.58kg (bare).

The RHS upright illustrated above comes in at 1.74kg and the keyed plate upright below comes in at 1.86kg.

I forgot to add the light weight racing uprights which weigh .898kg.

[Edited on 4/10/05 by Rorty]

Rescued attachment Cort_upright_02.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

cymtriks

|

| posted on 4/10/05 at 09:42 AM |

|

|

a few more questions..

Rorty,

Why can't the stub shafts be used in standard form? I've no idea what the standard ones look like and I assume that there is a good reason

for you to turn the ends down, I'm just trying to understand this mod. Is there a before and after pic?

I assume that what you end up with is a flange followed by a 16mm spigot. The flange buts up against the side of the 50x50 tube. The spigot goes

through two light interference holes to the other side of the 50x50 tube and protrudes by a few mm. You then weld around this protrusion to secure the

stub shaft.

What do your "top shelf" uprights look like, Are there any descriptions or pics?

|

|

|

Rorty

|

| posted on 4/10/05 at 01:05 PM |

|

|

quote:

Originally posted by cymtriks

Rorty,

Why can't the stub shafts be used in standard form? I've no idea what the standard ones look like and I assume that there is a good reason

for you to turn the ends down, I'm just trying to understand this mod. Is there a before and after pic?

I assume that what you end up with is a flange followed by a 16mm spigot. The flange buts up against the side of the 50x50 tube. The spigot goes

through two light interference holes to the other side of the 50x50 tube and protrudes by a few mm. You then weld around this protrusion to secure the

stub shaft.

What do your "top shelf" uprights look like, Are there any descriptions or pics?

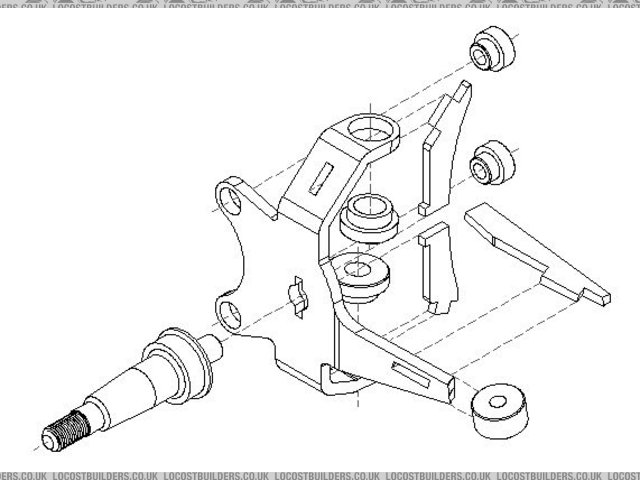

I don't follow your first question about using the stub shafts in standard form and turning the ends down. The stub axles I use start off as a

length of round bar, so the whole thing is turned down.

Yes, there's a flange with a spigot that's welded through the RHS. My CAD puter is off right now, but I'll grab a pic of one of my

stub axles in the morning.

The really light weight uprights are made from 1.6mm sheet and are keyed together. They have bolster washers welded into every hole for strength and

they also have closers welded into their open ends to aid stiffness. They're usually fitted with hollow parallel stub axles too.

The rod end bolts are made from tube to reduce weight and the SHCS for attaching the disc have oversized safety wire holes for additional weight

saving!

The discs themselves are aluminium with cut-outs, again, for lightness and the hubs are pretty minimalist too.

They're a lot more expensive due to the extra work involved, but they are very, very light.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

NS Dev

|

| posted on 4/10/05 at 02:02 PM |

|

|

quote:

Originally posted by gazza285

Its been a while since I've used a lathe in anger though, have to dig out the micrometers.......

Long time since I used a mike on my lathe, don't think It'd be as accurate as the mike anyway.

Verniers will be fine for making stub axles, you won't need better then 0.02mm for fitting cortina wheel bearings.

|

|

|

NS Dev

|

| posted on 4/10/05 at 02:04 PM |

|

|

quote:

Originally posted by Rorty

- I doubt if you would find any bolt-on stub axles and the cost of turning aa thread on a plain one would far exceed the cost of having someone weld

one on (if the DIY welder wasn't up to the job).

Incidently, I turn down the back of the stub axle to form a 16mm dia. spigot which goes right through the entire box tube and I then rose-weld it to

the other side of the RHS. This anchors the stub securely and really beefs up the whole upright.

- OK

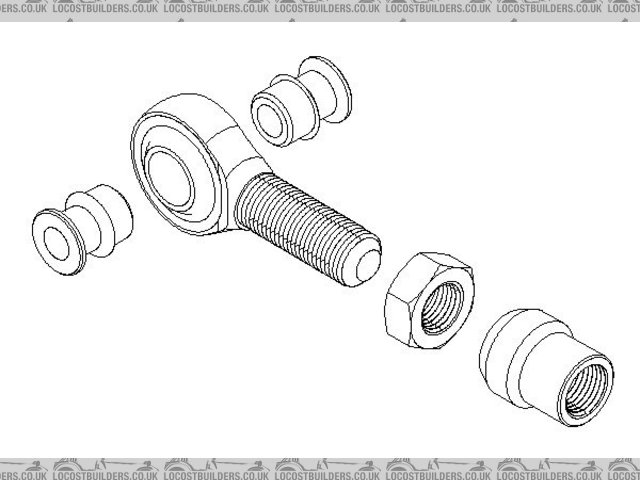

- Ah, sorry. Those are ball extenders! They extend the ball bearing and effectively increase the bearing surface and thus the angle of operability.

They also have a convenient spacer built-in. The extenders also step down the size of the bolt through them, normally by just one size, so you'd

need to remember that when drilling the holes in the uprights.

I usually make them up for the job in hand from stainless steel. See pic below.

- No worries; the RHS is nothing more than common 50 x 50 x 3 mild steel box tube and the stub axles vary but IIRC, the grade you'd use in the

UK is something like EN16. Many trailer stub axles aren't even as good as that yet they hold up OK.

they would indeed be EN16. Probably EN16T, the commonly available tempered variety. If you wanted to be totally over the top you could use EN24/EN24T

but in either case the welds would be the weak point...............in fact, on most locost chassis, the chassis would fail long before the upright

did!

|

|

|

NS Dev

|

| posted on 4/10/05 at 02:07 PM |

|

|

Not wishing to take trade away from anybody on here, but my old famous quote kicks in once more!!!...............................ring GB Engineering

in Nantwich!

They make strong, lightweight uprights, complete with alloy hubs, bearings, brake disc (to suit bike calipers) and steering arms, for £250 a pair. As

tested by around 1000 autograssers most weekends in the UK.

|

|

|

Rorty

|

| posted on 4/10/05 at 09:37 PM |

|

|

quote:

Originally posted by NS Dev

Not wishing to take trade away from anybody on here, but my old famous quote kicks in once more!!!...............................ring GB Engineering

in Nantwich!

No worries, I'm only offering information.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Avoneer

|

| posted on 4/10/05 at 10:15 PM |

|

|

Any pics ND Dev - they sound interesting.

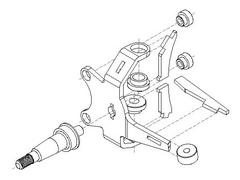

Anyone seen the Stuart Taylor ones?

Rescued attachment 007.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 4/10/05 at 10:16 PM |

|

|

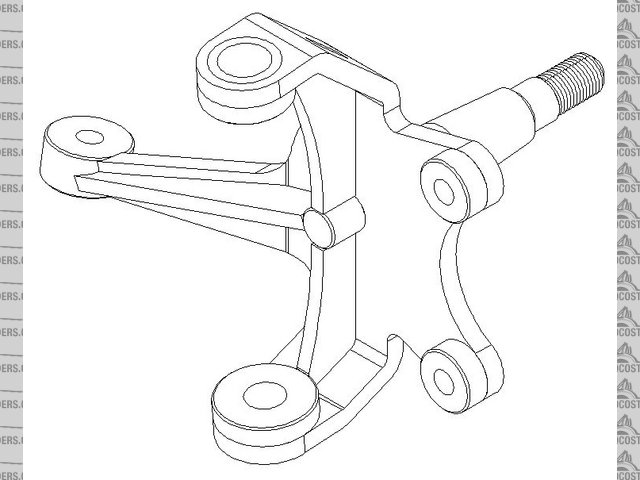

And another pic:

Rescued attachment 002.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

NS Dev

|

| posted on 4/10/05 at 10:16 PM |

|

|

.................and interesting info at that....................the "ball extenders" are a nice idea that I haven't seen before. I

have made chamfered washers as spacers to do a vaguely similar thing but they look like a much neater way to do it!

|

|

|

Rorty

|

| posted on 4/10/05 at 10:19 PM |

|

|

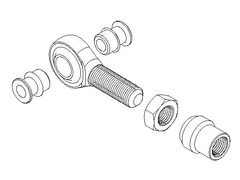

Here's the stub axle.

Rescued attachment Cort_upright_03.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Rorty

|

| posted on 4/10/05 at 10:31 PM |

|

|

Here's the ball extenders too.

Rescued attachment ball_extenders_01.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

MikeR

|

| posted on 4/10/05 at 10:48 PM |

|

|

Rorty, Have i read this correctly, the upright just above this post is made from 1.6mm steel?

Would you seriously reconmend that for a road going application?

I'm just a little shocked as it seems unfeasible 'light' to my un-educated brain.

|

|

|

Rorty

|

| posted on 4/10/05 at 11:03 PM |

|

|

quote:

Originally posted by MikeR

Rorty, Have i read this correctly, the upright just above this post is made from 1.6mm steel?

Would you seriously reconmend that for a road going application?

I'm just a little shocked as it seems unfeasible 'light' to my un-educated brain.

NO! NO! NO! The ones made from 1.6mm sheet are similar in design to the very first pic I posted. They're constructed from keyed pieces into a

square tube shape but are more complex.

The benefits are that the design is not reliant on available RHS sizes and the shape is basically unlimited; the steering arms can be tapered etc.

The steel plate upright just above is made from 8mm steel plate with 6mm braces, though for a Locost you could probably even get away with 6mm for the

whole thing.

I haven't tried it though, so don't go making some from 6mm and then blaming me if you ditch the car.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Rorty

|

| posted on 4/10/05 at 11:14 PM |

|

|

I just found this source for trailer stub axles, hubs and studs

etc.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Peteff

|

| posted on 4/10/05 at 11:25 PM |

|

|

I had some unbraked suspension units from them for a trailer I built my mate last year. They were good quality items and quick delivery.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|