JoelP

|

| posted on 5/8/05 at 03:55 PM |

|

|

all i can add is that people have used rod ends in that orientation on race cars for years, and a panhard rod is going to involve less angular

movement due to its greater length.

|

|

|

|

|

Avoneer

|

| posted on 5/8/05 at 04:51 PM |

|

|

Ok,

Solution so far from the though pool provided:

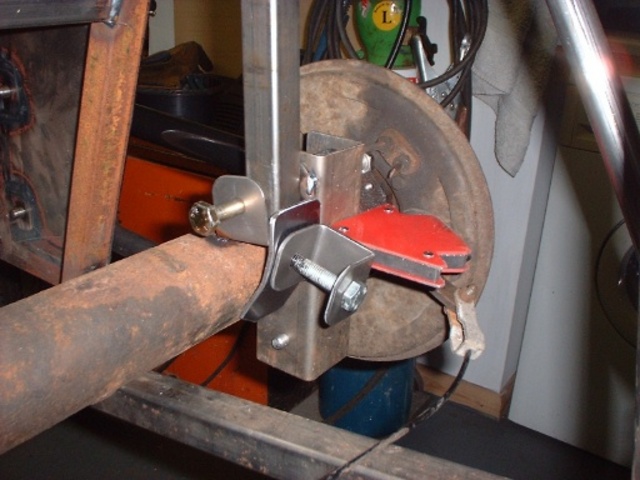

1) Rear brackets as they are at the moment

Rescued attachment 1.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 5/8/05 at 04:54 PM |

|

|

2) Flat 3mm plate support for the shock bracket - curved to fit the profile of the axle tube and angled lower edge for maximum weld area. Note the

hole!

Rescued attachment 2.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 5/8/05 at 04:55 PM |

|

|

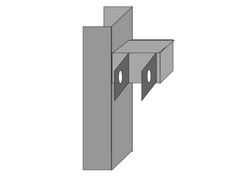

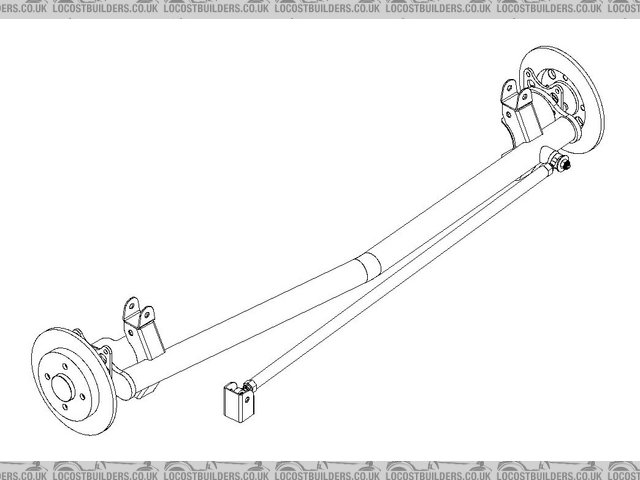

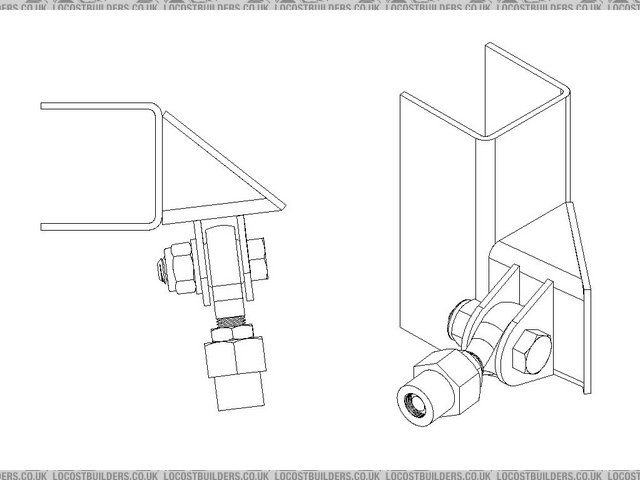

3) Panhard rod bracket which can be fully welded in place and a gusset added to the back to tie it to the trailing arm bracket. Bolt goes all the

way through and you can still get a nut on the inside. Although it is on a slight downward angle, the rose joint will more than cope with this.

[Edited on 5/8/05 by Avoneer]

Rescued attachment 3.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 5/8/05 at 04:57 PM |

|

|

How am I looking?

And yes Rorty, I really was waiting for your reply as I think you have a lot that people can learn from, even if they don't listen.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Peteff

|

| posted on 5/8/05 at 05:37 PM |

|

|

Mine are the wrong way on then. They are set level and can only travel 3" which is well within their range. They've been alright for the

last 4 years so I'm not going to change them now. If you weld a piece of tube to the back of your axle mount then weld your bracket to the back

of it it would be much easier. The way you are showing there looks like a bodge Pat.

Rescued attachment hanger.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Canada EH!

|

posted on 5/8/05 at 08:26 PM posted on 5/8/05 at 08:26 PM |

|

|

The bolt welded to the axle bracket is a good design, however it is never a good idea to have mounts in single shear, re-enforce the nut end with a

small bracket.

|

|

|

Rorty

|

| posted on 6/8/05 at 04:03 AM |

|

|

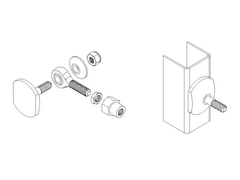

Pat, your last photo, while providing a double shear bracket, is a bit messy IMHO. I think the pocket you are creating between the axle housing, the

radius rod bracket and now the Panhard rod bracket will be a dirt and moisture collector which could result in the threads rusting solid, What would

you do then? You'd probably have to cut stuff away to repair it.

I stand by what I said before; a double shear mount is always preferable to a single shear one, but in this case, I think, due to the difficulties of

successfully placing the nut, a single shear spigot would be the better solution.

Having said that, I don't recommend just hacking the head off a high tensile bolt and welding it onto the radius rod bracket. Welding the bolt on

would destroy the temper of the bolt, virtually reducing it to a much weaker bit of mild steel.

The second problem with just welding a bolt onto the rear of the bracket is that it could eventually flex the thin mild steel bracket enough to pull

the bolt and weld out.

A much better solution would be to make a mushroom shaped spigot from something like EN16T (or 4140) and weld that on. The large head would be a much

better load spreader, plus the size and mass of the head would keep the heat from the HAZ away from the all-important spigot and threads.

If you decide to go this route, don't forget to place a safety washer on the spigot before the lock nut goes on. This will prevent the rod end

from coming off over the spigot and nut in the event it separates from its race.

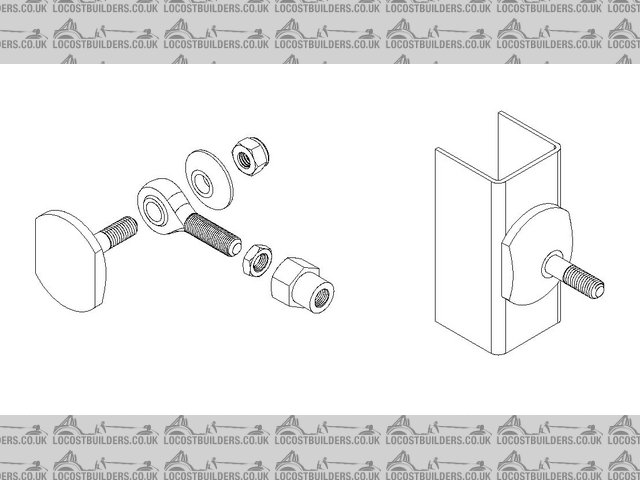

Rescued attachment Panhard_mount_01.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Rorty

|

| posted on 6/8/05 at 04:14 AM |

|

|

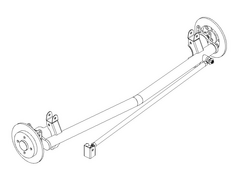

For anyone that's interested, this is my take on a similar fitting for a DeDion set-up.

Rescued attachment DeDion_01.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Rorty

|

| posted on 6/8/05 at 04:20 AM |

|

|

Damn it! I've been giving this quite a bit of thought. Pat, to go back to your first photo in this thread:

I like the simplicity of it, but it needs a little forethought prior to just welding it on.

Firstly, as can clearly be seen, some spacers will be required to properly position the rod end within the bracket. Do not use washers, because they

are seldom the correct thickness with the result that you will no doubt put some stress on the bracket when the nut and bolt are tightened. Also, the

washers are inherently flat and will foul the rod end when the axle moves up and down.

The ideal spacers for this scenario would be simple hollow cylinders of the correct length with a 30 degree bevel around one end.

The next quandary is the actual functionality of the rod end; in this orientation, will it cope with the angles involved with the travel of the axle?

The answer is probably yes, but it's necessary to confirm the rod end's angular limits. You can either get the info from the

manufacturer's catalogue or your supplier. Once that's established, you then need to define the axle's travel.

Let's say for the sake of this discussion that the axle has a total of 125mm of travel (comprised of 75mm of bump and 50mm of droop). You now

need to plot the arc that the axle end of your Panhard rod travels through for a total of 125mm of travel. If this angle is (well) within the

manufacturer's stated range for the rod end, then mounting the rod end in this way will actually work OK.

If the bump and droop figures were equal, then mounting the rod horizontally (as viewed from the rear) would put the rod end slap in the middle of its

travel zone and all would be well. However, as there will inevitably be more bump than droop, the bracket on the axle may need to be mounted slightly

above the horizontal to off set the higher angularity required for bump and keep the rod end within its range.

It's a simple task to plot the relative travel and angles on a sheet of paper to establish the position of the bracket mid-way in the rod

end's range.

NOTE: This may not be my final word on the matter!

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Avoneer

|

| posted on 6/8/05 at 08:23 AM |

|

|

Hi Rorty,

Thanks - a lot of information there for me to pnder on!

I'll get the speck of the rose joint - it's a good one (I think) with carbon fibre insert.

The other end of my panhard rod has the usual tube eye and poly bushes - could turn it round and use this end attached to the back of the axle?

I do prefer (due to the simplicity) the single shear option - I was thinking of welding another piece of 3mm plate right around the trailing arm

bracket from the front edge (over the top of the trailing arm eye) all the way back, down and across the bottom. Then a short, but thick boss welded

onto the 3mm plate and then drilled and tapped all the way through the boss, new 3mm plate and the 3mm trailing arm bracket. And then bolting the rose

joint onto the end of this boss with a big washer.

Not planning on racing the car if that makes any difference to the stresses it will be under - but saying that, shouldn't make any difference as

if it's good enough for racing, it should be good enough for the road.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 6/8/05 at 08:32 AM |

|

|

Can always do it like Pete has suggested by welding a section of box vertically onto the back of the trailing arm bracket with two horizontal

"lugs" for the rose joint.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Rorty

|

| posted on 6/8/05 at 08:49 AM |

|

|

I like Pete's solution too and I had thought of doing it that way, but it has the effect of shortening the length of the Panhard rod and it

really wants to be as long as is feasibly possible.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Avoneer

|

| posted on 6/8/05 at 08:58 AM |

|

|

So what size box would "do the job"?

If I use 1" square sticking horizontally out of the dead middle of the back of the trailing arm bracket, say for 2" and weld two lugs to

this for the panhard rod, how would that be? Or do I need a right big chunky piece of box?

At least the lugs don't have to be far apart due to the width of the rose joint.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

JoelP

|

| posted on 6/8/05 at 09:23 AM |

|

|

if i were to do it petes way, i would use a piece of 50x50x3mm box section, cut to a diagonal and with a 3mm plate on the back. This would ensure that

the bracket fits with no overhang.

If you need some of this tube, i can bring it to the meet.

|

|

|

Avoneer

|

| posted on 6/8/05 at 09:26 AM |

|

|

How about a backward bracket with two lugs welded on the base of it?.JPG)

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Rorty

|

| posted on 6/8/05 at 01:44 PM |

|

|

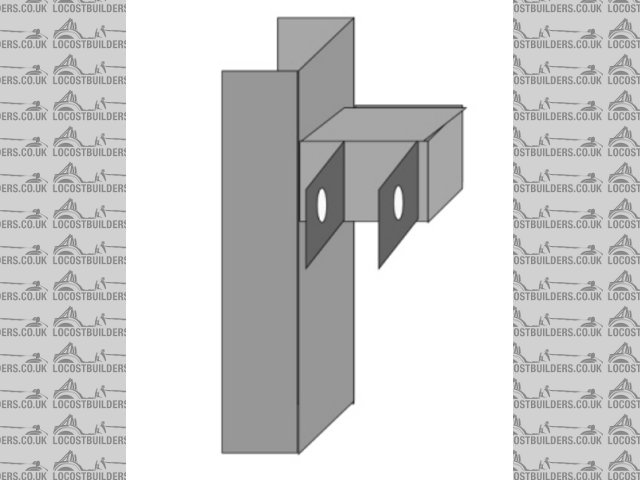

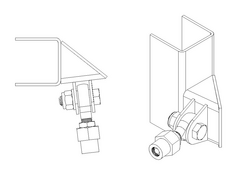

That would do, but JoelP's triangular version would be neater and stronger. I would angle the RHS so the tabs are aligned with the Panhard

rod's axis, then sandwich the tabs either side of the rod end and bolt the lot solid before finally tack welding them to the RHS. Only tack the

tabs at this point as you don't want to get any heat into the rod end.

Rescued attachment Panhard_mount_02.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Peteff

|

| posted on 6/8/05 at 01:49 PM |

|

|

The old back to front bracket ploy eh !

Strangely enough that was my first thought, but I have loads of 3mm 50x50 box and a chop saw burning a hole in my pocket, figuratively speaking.  .

If I did this to mine it would make it 30mm shorter which I don't think would have too much overall effect on the arc of the rod end .

If I did this to mine it would make it 30mm shorter which I don't think would have too much overall effect on the arc of the rod end

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Avoneer

|

| posted on 6/8/05 at 02:36 PM |

|

|

Cheers guys and Rorty for the pic - that'll be the solution.

Can I mount the panhard rod the other way round with this bracket on the passenger side as this would give me more central clearance for the original

Escort handbrake mechanism???

Both side of the rear "bay" are triangulated unlike the book where only the side that has the panhard rod is.

Thanks.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Peteff

|

| posted on 6/8/05 at 06:25 PM |

|

|

If it's the rod operated handbrake that goes through the loop on the rear of the diff cover you can mount the brake rod to whichever side is

most convenient.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Avoneer

|

| posted on 6/8/05 at 10:03 PM |

|

|

Or the panhard rod???

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Peteff

|

| posted on 6/8/05 at 10:30 PM |

|

|

Yes, no reason not to if both sides are braced

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Avoneer

|

| posted on 6/8/05 at 10:49 PM |

|

|

Thanks Pete and Rory.

I'll update once made.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

SkinnyG

|

| posted on 7/8/05 at 04:55 AM |

|

|

For something a little different, a significantly lower panhard. I think I'm alone on this one.

Greg

Kelowna BC Canada

http://www.gwellwood.com

|

|

|