AGK7

|

| posted on 17/7/05 at 08:56 AM |

|

|

Inboard Front Suspension

Hi all,

I know this topic has been discussed to death and I have spent a lot of time reading through the archives but I have a few questions for the brains

trust.

The benefits of inboard front suspension seem fairly well accepted, less unsprung weight, progressive spring rates, and aerodynamic for what thatís

worth. I wonder why more havenít had a go Iíve seen only a few locost clubbies who have tackled inboard shocks.

My thinking is as follows, try something that makes the car a little different and hopefully have a final product that also offers some more

adjustability. I am planning on designing a scale model of the push-rod and rocker as their movement is only in one plan this becomes quite straight

forward. My goals as I understand them are

1) Progressive spring rate

2) 1:1 ratio of wheel movement to spring compression

3) Push rod attachment near to bottom ball joint to avoid leverage

Whats the catch with attempting such a job, I am designing my bones to suit so I figure I might take it one step further. I am thinking the rocker

will be made from plate steel with rose joints on the push rod, the rocker pivot I am yet to finalise however I have noticed this set up

http://www.seven-nl.tk/

which looks nice.

So helps pleases, warnings comments on my design goals horror stories of those who have tried and failed/succeeded. I have also seen the Bobís Locost

site which has help inspire this posts. Is it really that hard or have others just not thought it worth the trouble??

Thanks in advanced

Andrew

Australia

PS sorry for the long winded post

|

|

|

|

|

scoobyis2cool

|

| posted on 17/7/05 at 09:34 AM |

|

|

Hi Andrew, welcome to the site. Sounds like an interesting idea, I don't see any reason it couldn't be made to work in a 7 and as you say

it has a number of benefits over the traditional outboard design. (Having said that, outboard suspension is used on some of the best handling cars

around, such as the Lotus Elise, so it's not something to disregard completely!).

I was looking through Liam's photo archive yesterday - HERE.

He's made a nice looking inboard set up, maybe you could get in touch with him for some pointers. I'm sure other people have done it too

but I don't know who they are!

Good luck with the build, I look forward to seeing how it turns out.

Pete

It's not that I'm lazy, it's that I just don't care...

|

|

|

JonBowden

|

| posted on 17/7/05 at 09:42 AM |

|

|

I'd be interested in your results. I have little practical experiance in car construction (I've thought about it for many years but have

never had the space to try), but I believe one of your points may be a popular myth.

As far as I can see, if you use a 1:1 ratio of wheel movement to spring compression, you will not reduce unsprung mass, although some of the mass will

be on the other side of a pivot.

If you used a setup such that the spring/damper moved say half as much as the wheel (requiring a stiffer spring / damper) then this would reduce

unsprung mass.

Jon

|

|

|

craig1410

|

| posted on 17/7/05 at 11:28 AM |

|

|

Jon,

Doesn't the reduction in unsprung mass come from the fact that the shocker is working effectively "upside down" in an inboard design

where it is the lighter top section of the shocker which moves in reaction to suspension bump rather than the heavier bottom section? In a typical

outboard design the lighter top section of the shocker is fixed to the chassis (sprung side) and it is the heavier bottom section which is attached to

the unsprung side.

Could be wrong but this is my understanding unless someone points out the error of my logic.

Cheers,

Craig.

|

|

|

rick q

|

| posted on 17/7/05 at 12:07 PM |

|

|

The Fraser (built in NZ) comes as either conventional or inboard front suspension. The rockers are available in a couple of different ratios in Cast

aluminium, though they should be relatively straight forward to fabricate in steel.

There are some good photos down at the bottom of this page :-

http://www.billzilla.org/fraser.htm

|

|

|

rick q

|

| posted on 17/7/05 at 12:09 PM |

|

|

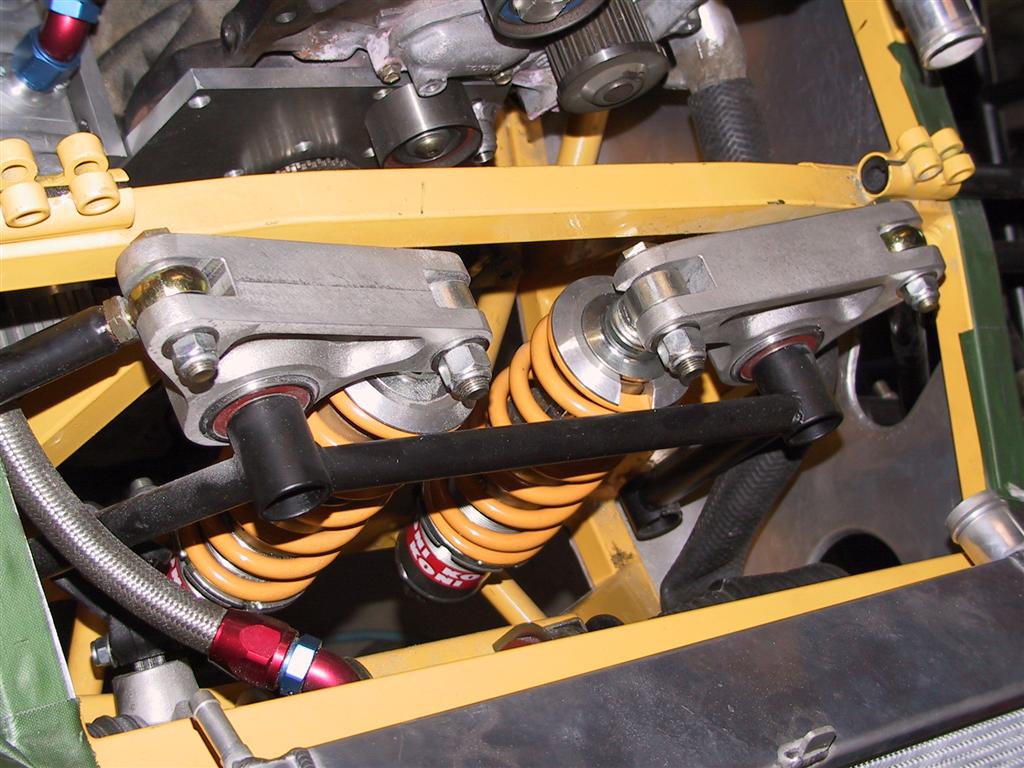

and here's the photo

|

|

|

JoelP

|

| posted on 17/7/05 at 12:29 PM |

|

|

IMHO, the extra weight of the mechanism will outweigh any possible reduction in unsprung mass - the is both the mass of the pushrod and the rocker to

add on, and as craig says, having the shocker effectively upside down might save a few 100 grams.

The other three benefits as i see it are the slight reduction in the drag coefficient, the potential to change you effective spring rate just by

moving the rocker, and the fact that you can make the pushrod mounting point on the wishbone a little closer to the ball joint that you could with the

body of a damper in the way. Hence less bending force on the bones.

Then there is also the small benefit of it looking quite clever, but that doesnt count for much.

However, i cant imagine it being hard to set up.

|

|

|

pbura

|

| posted on 17/7/05 at 04:34 PM |

|

|

I'll second what Joel said about the pushrod and rocker adding to unsprung weight.

What I like about inboard shocks:

1. Can use cheap and plentiful second-hand motorcycle shocks.

2. By altering the rocker ratios, you can change the wheel rates of your springs.

3. Ride height can be adjusted with the push/pull rods.

The rocker ratios needn't be 1:1, but can be whatever you need to get the wheel rate you want.

Recommended reading: Allan Staniforth's Race and Rally Car Sourcebook.

Pete

|

|

|

JoelP

|

| posted on 17/7/05 at 05:19 PM |

|

|

just thought, it could also be combined with the anti roll bar, if you wanted one, nice and tidy and all hidden. So thats one more possible benefit!

|

|

|

AGK7

|

| posted on 18/7/05 at 03:25 AM |

|

|

Thanks for the feedback guys.

Rick that is a lovely car indeed i trust you have no regrets about buying it!!

One of the benefits of a 1:1 ratio is it does make calc on wheel rates very easy.

I suppose a bit of it is wank factor but it would be nice to try something a little different. As mentioned ride height adjustment also becomes much

easier.

Any more links to design info or examples much appreciated.

Cheers

Andrew

|

|

|

rick q

|

| posted on 18/7/05 at 03:40 AM |

|

|

Andrew - the links refer to Bill Sherwood's Fraser which is about to be registered. Mine is the red one in the avatar with a 16V 4AGE - just as

lovely though!!!

|

|

|

alfasudsprint

|

| posted on 18/7/05 at 11:23 AM |

|

|

Take a look at the Caterham website, their all new CSR has in board front suspension.

|

|

|

smart51

|

| posted on 18/7/05 at 11:33 AM |

|

|

extend the top wishbone so that it extends inwards of the pivots. Use this extension to push down on your coil-over-dampers. No need to have push

rods. The extra weight is only the length of the extension bar (not much).

In terms of un-sprung weight reduction, all of the coil / damper is sprung. Better than that, the top of the damper moves in the opposite direction

to the wheel. Does that count as negative un-sprung weight?

Not having a push rod means even better aerodynamics.

|

|

|

NS Dev

|

| posted on 18/7/05 at 11:51 AM |

|

|

..................all of which reminds me of something I looked at doing on the grasser to improve damper control.

Use the rocker inboard shocker setup, but mount the lower end of the inboard shock on a bellcrank and operate the bellcrank via a pullrod from the

outer end of the upper wishbone. That way you can compress the damper from both ends at the same time, giving greater damper movement for a given

wheel movement.

I then realised I could do the same with cantilever upper wishbones, then realised they wouldn't fit, so had to go back to the other plan, then

couldn't be bothered!!!

|

|

|

JoelP

|

| posted on 18/7/05 at 09:13 PM |

|

|

quote:

Originally posted by smart51

extend the top wishbone so that it extends inwards of the pivots. Use this extension to push down on your coil-over-dampers. No need to have push

rods. The extra weight is only the length of the extension bar (not much).

In terms of un-sprung weight reduction, all of the coil / damper is sprung. Better than that, the top of the damper moves in the opposite direction

to the wheel. Does that count as negative un-sprung weight?

Not having a push rod means even better aerodynamics.

not specifically a bad idea, but the bending force on the upper wishbone would be considerable  Beefing it up would solve this, but then the mass is

climbing again. I think it is likely (personal opinion only though) that a pull/push rod would weigh less than the additional bracing required for the

upper wishbone. Beefing it up would solve this, but then the mass is

climbing again. I think it is likely (personal opinion only though) that a pull/push rod would weigh less than the additional bracing required for the

upper wishbone.

The inboard mass would also have to be added onto the unsprung mass, not deductied, cos it all adds to the inertia/rotational momentum about the

wishbone pivots, which is what unsprung mass actually refers to.

|

|

|

ady8077

|

| posted on 18/7/05 at 09:25 PM |

|

|

Hi

Most Sylva derived cars have inboard suspension, the top arm is slightly heavier than a book wishbone, but the bottom arms are probably lighter

Adrian

Rescued attachment in suspension.jpg

|

|

|

JoelP

|

| posted on 18/7/05 at 09:36 PM |

|

|

that does look quite good

|

|

|

AGK7

|

| posted on 18/7/05 at 11:41 PM |

|

|

Hey guys,

The rocker arm type set-up was definitely something else I was looking at. I have seen a local 7 type car which uses this but on the bottom bone.

Mind you using the top bone as per pic above certainly does clean the area up quite a lot. One of the problems as I understand of the rocker arm type

is the heavy loads on both the rocker arm as well as the pivot points. Neither of these are insurmountable though and plenty have already gone

there.

This is a photo of the Alison Clubman an aussie but machine with a bottom rocker arm.

can't seem to get the image to show, it is however the only one in my alburn. (any tips on how to make this link work??  ) )

Thanks again.

AndrewK

|

|

|

Liam

|

| posted on 19/7/05 at 12:28 AM |

|

|

Thanks for the big-up pete!

I went for rocker arm suspension - all the benefits of inboard without the hassle of working out the geometry relating to the movement of pushrods,

bellcranks etc etc.

Yes the pivot is highly loaded, but (intuitively - I haven't calculated) no more than the pivot of a bellcrank in a pushrod system. Nothing an

M12 bolt cant handle - i'd worry more about using 2 bits of 3mm steel for the bracket, which is why i doubled my pivot brackets up to 6mm (but i

have a high leverage, therefore high pivot load in my softest setting).

Bending of the wishbone is the main problem - you just have to make the top bone nice and stiff in that direction. A triangulated structure ideally,

but i've seen plenty of designs that just use beefy steel to resist bending.

The main reason I went for inboard is the scope for plenty of wheel rate adjustment. I have a selection of mounting holes for the shock on the inner

end of my rockers to play around with suspension settings easily. This is just as achievable with a pushrod design of course.

Best of luck,

Liam

|

|

|

rick q

|

| posted on 19/7/05 at 12:36 AM |

|

|

The loads on the rockers are high. If you look back at the picture I posted on the previous page, the rockers were originally supported on

cantilevered studs welded to the cross frame. An additional pipe support is now added (the black frame in front of and connecting the rocker pivots)

which stiffens the whole thing up considerably.

|

|

|

AGK7

|

| posted on 20/7/05 at 06:40 AM |

|

|

One other problem with using the top rocker arm is finding a ball joint that will put up with the load.

I am using Toyota landcruiser tie rod ends as my top ball joints going into a Gemini upright, do people this this would put up with the extra load if

the shocks were transferred from the bottom to the top bone??

Landcruisers are pretty big heavy cars and being designed for off road use i can imagine that there would be heaps of load going through even if it is

steering only.

Any thoughts?

Cheers

Andrew

|

|

|

britishtrident

|

| posted on 20/7/05 at 07:00 AM |

|

|

For ball joints I think Metro top ball joints have been used in the past.

But is it really worth all the complication -- I think not as the main reason for using inboard suspension on single seaters is aerodynamic. The

unsprung weight/mass arguments don't hold much water when looked at in detail, you can save much more by careful choice of rims and tyres.

The major disadvantage is the extra complication and stifness required in the front bay of the chassis and wishbones.

For a genuine reduction in unsprung mass without too many complications compound torsion bars (as per Lotus 72) are an idea --- a mid to late 80s

Honda or Rover 213 would be a suitable donor. For use on a lighter car the bar angular spring rate can be reduced by machining or better grinding down

the diameter of the centre part of the compound bar.

[Edited on 20/7/05 by britishtrident]

|

|

|

britishtrident

|

| posted on 20/7/05 at 07:06 AM |

|

|

quote:

Originally posted by agk

snip

I am using Toyota landcruiser tie rod ends as my top ball joints going into a Gemini upright, do people this this would put up with the extra load if

the shocks were transferred from the bottom to the top bone??

Landcruisers are pretty big heavy cars and being designed for off road use i can imagine that there would be heaps of load going through even if it is

steering only.

Any thoughts?

Cheers

Andrew

The problem is that rod ends are self adjusting by a spring pressing against the cup the that the lower surface of the ball joint bears on. When the

ball is pressed into the socket the diaphram spring that provides the self adjustment is compressed effective negating its effect.

|

|

|

AGK7

|

| posted on 20/7/05 at 11:55 AM |

|

|

what about a spherical bearing installed horizontally?? Can these put up with the vertical loads if they are installed horizontally? I am pretty

sure i have seen this done, just seems that the inner ball would pop straight out of the outer ring? If they could then an adapter such as

http://www.raceleda.co.uk/ancilliaries.aspx

could be made up to suit? Sorry for so many question.

Cheers

Andrew

|

|

|

chrisf

|

| posted on 20/7/05 at 01:37 PM |

|

|

I'm using rod ends exactly as you describe. I have a couple of designs of an inboard suspension idea in the Archived Files secion on my website

(give me a few minutes to update). Some things to consider is the packaging. I eventually got discouraged and dropped the idea. I still think it can

be done, but it is difficult. Have a look at Mathew_1 's inboard idea. His is very nice. Or Rob's BEC ZX-12.

--Chris

|

|

|