Getting the right amount of castor

andyd - 25/4/08 at 09:20 AM

Firstly, sorry for posting about this well discussed subject *again* but my searches haven't turned up an answer I can either relate to or

possibly understand.

I'm hoping to have my own design uprights made and intend to make the KPI around the 10deg mark. I'm aiming to then start with 3deg negative

castor and "work back from there" so to speak until I've got enough self centring and (more importantly) the right about of negative

camber when turning. I'm using an Escort mkII steering rack but the steering arms will also be custom so I'm hoping to achieve decent

Ackerman but haven't really thought this bit through yet.

So my question is...

Should I make the top wishbones symmetrical and have the mount points further back than "usual" (in relation to the bottoms) or make them

asymmetrical (as per the book) and have them more "lined up"?

Is there a valid reason not to just mount the top wishbone further back (other than shock clearance) and keep it symmetrical vs going asymmetrical to

get the castor?

If the only reason to make them asymmetrical is for clearance (other than getting the castor that is) then I could mount the shocks inboard and use a

push rod which would give more clearance.

I'm sure once I've CAD'd this it'll be totally obvious to me but work is being a b1tch at the moment and I haven't had time

to fiddle with the CAD of late.

907 - 25/4/08 at 09:47 AM

Hi Andy,

I have 'Tina uprights and made my first bones as per the book.

Doh!

I have since remade them with 22mm off set to give better driveability.

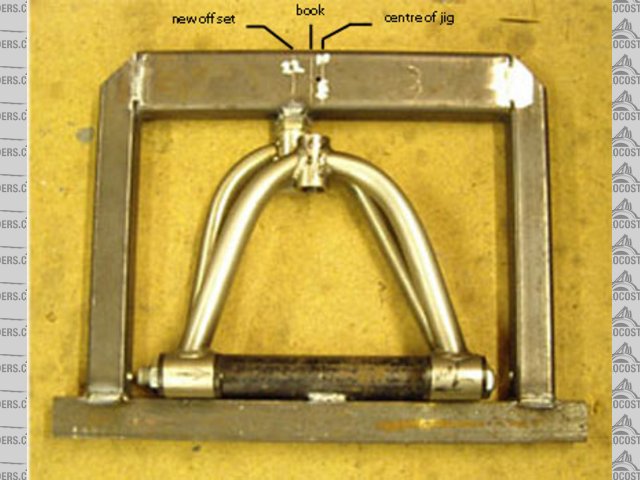

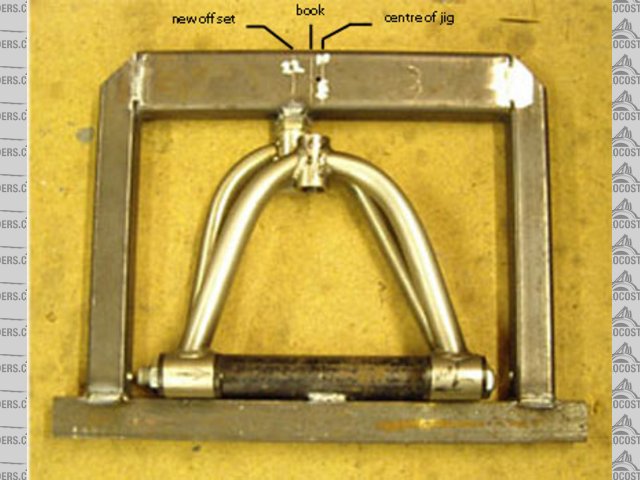

I have a jig that I made (see pic) which if this is any good to you you would be welcome to borrow.

The tube doesn't have to be curved as the jig just locates the three bushes.

If your uprights will differ from the 'Tina ones then just ignore this post.

Atb

Paul G

Rescued attachment wb-jig-s.jpg

drlloyd - 25/4/08 at 09:59 AM

The pros and cons can be discussed at length but I would (and have!) have the desired degree of castor built into the top wishbones. Then make the top

wishbone brackets about 20mm wider than necessary to allow the use of machined spacers for further final adjustment of castor when setting up the car.

andyd - 25/4/08 at 10:06 AM

quote:

Originally posted by 907

If your uprights will differ from the 'Tina ones then just ignore this post.

They will differ as I think the 'Tina's KPI is something like 4 or 5 degs?

I won't ignore your post though cos just the picture of your jig is useful.

britishtrident - 25/4/08 at 10:10 AM

Any negative caster on a rwd car is bad news, the steering will tend self servo to full lock and put you into the ditch.

Cars which are light at the front need a lot of caster.

Depending on your layout base the amount of caster you use on a car with similar weight over the front wheels and king pin inclination ---- ie if you

are building a Seven style car get data for a 1960s Lotus or Trumph Spitfire.

andyd - 25/4/08 at 10:16 AM

quote:

Originally posted by drlloyd

Then make the top wishbone brackets about 20mm wider than necessary to allow the use of machined spacers for further final adjustment of castor when

setting up the car.

Yep, I was intending to keep the standard 36mm bush tube length with 2mm of bush protruding each end and a crush tube length of 44mm then make my

brackets from 60mm x 40mm x 3mm RHS so thereby having 5mm each end for fine adjustment.

andyd - 25/4/08 at 10:22 AM

quote:

Originally posted by britishtrident

Any negative caster on a rwd car is bad news... Cars which are light at the front need a lot of caster.

Depending on your layout base the amount of caster you use on a car with similar weight over the front wheels and king pin inclination

It'll be similar to an Elise which I believe has 12deg KPI but not sure about the castor. From Des Hamill's book I'm taking his

"between 9-12 KPI with 10 being ideal" and "start at 3degs castor going up to 7 with 7 being a maximum"... that's

paraphrasing cos I don't have the book here at work.

So based on your previous comments how do I stand? The Elise is RWD *and* it's light at the front so do your first two statements conflict?

Edit to say... do I mean negative castor? I mean the upright angles to the rear of the car at the top vs the bottom i.e. "leans back". Is

that negative or positive castor?

Edited again to say I've found some details about the Elise and it seems to have 12KPI with 3-4degs castor and it says + so I assume I've

got my +/- the wrong way wrong and I actually mean I want positive castor.

[Edited on 25/4/2008 by andyd]

907 - 25/4/08 at 10:30 AM

quote:

Originally posted by andyd

I won't ignore your post though cos just the picture of your jig is useful.

OK Andy, glad to be of some use.

People tend to make jigs that don't allow access to the welder.

No point in a jig if you have to take the piece out to weld the other side. (IMHO)

As your local, if you ever fancy a cuppa, call in.

From you, I'm just the other side of Sudbury.

Atb

Paul G

andyd - 25/4/08 at 10:34 AM

quote:

Originally posted by 907

No point in a jig if you have to take the piece out to weld the other side. (IMHO)

As your local, if you ever fancy a cuppa, call in.

From you, I'm just the other side of Sudbury.

Cheers Paul. I will take you up on the cuppa offer cos it'd be good to see your aluminium talents up close.

And a very good point about the "double-sided" jig. I'd not even considered that until you just mentioned it.

britishtrident - 25/4/08 at 10:40 AM

quote:

Originally posted by andyd

quote:

Originally posted by britishtrident

Any negative caster on a rwd car is bad news... Cars which are light at the front need a lot of caster.

Depending on your layout base the amount of caster you use on a car with similar weight over the front wheels and king pin inclination

It'll be similar to an Elise which I believe has 12deg KPI but not sure about the castor. From Des Hamill's book I'm taking his

"between 9-12 KPI with 10 being ideal" and "start at 3degs castor going up to 7 with 7 being a maximum"... that's

paraphrasing cos I don't have the book here at work.

So based on your previous comments how do I stand? The Elise is RWD *and* it's light at the front so do your first two statements conflict?

Edit to say... do I mean negative castor? I mean the upright angles to the rear of the car at the top vs the bottom i.e. "leans back". Is

that negative or positive castor?

Edited again to say I've found some details about the Elise and it seems to have 12KPI with 3-4degs castor and it says + so I assume I've

got my +/- the wrong way wrong and I actually mean I want positive castor.

[Edited on 25/4/2008 by andyd]

I am pretty sure the Elise geometry isn't that different from the MGTF istr that uses 5 degrees of positive caster and 11 degrees kpi.

You could save your self a lot of bother just using MGTF uprights --- these are ideal for rocker front wishbones.

Most of the MGTF front suspension comes straight off the Metro ---- uprights have drive shafts stripped out and I think are swapped left to

right.

907 - 25/4/08 at 10:43 AM

quote:

Originally posted by andyd

quote:

Originally posted by 907

No point in a jig if you have to take the piece out to weld the other side. (IMHO)

As your local, if you ever fancy a cuppa, call in.

From you, I'm just the other side of Sudbury.

Cheers Paul. I will take you up on the cuppa offer cos it'd be good to see your aluminium talents up close.

And a very good point about the "double-sided" jig. I'd not even considered that until you just mentioned it.

Any time mate. Just U2U for my post code.

Promise not to look too close though, it's not up to Trev D's standard.

Paul G

britishtrident - 25/4/08 at 10:46 AM

MGTF front end

andyd - 25/4/08 at 10:50 AM

quote:

Originally posted by britishtrident

I am pretty sure the Elise geometry isn't that different from the MGTF istr that uses 5 degrees of positive caster and 11 degrees

kpi.

That could be good. I was considering using the MGTF engine/gearbox as opposed to a Haybusa engine anyway. Plus I have a mate who has one... I'll

have to take a look at his when I next see him.

Cheers.

ps. I did mean positive castor not negative. Looked it up on Wiki.  I may have also meant castEr not castOr but I'm not sure about that either!

I may have also meant castEr not castOr but I'm not sure about that either!

drlloyd - 25/4/08 at 11:50 AM

I have between 10-11 degrees KPI and 6 degrees of castor.

Ive done a great deal of research into the suspension geometry of my car, bought books by Staniforth, Hamill,etc and have got a great deal of advice

from a very successful, senior engineer who spends his spare time building and competing in hillclimbs and sprints.

The problem is, a lot of the information conflicts slightly! So really any advice that we can all give should be treated with care and you will not

get an exact answer.

So really any advice that we can all give should be treated with care and you will not

get an exact answer.

Me and a mate are currently building a Rover V8 seven style kitcar so any information I give you is based on decisions we have made for that,

unfortunately I cannot yet tell you how it drives!