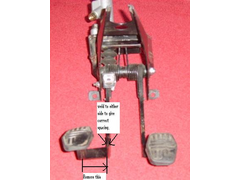

Here is a pic

Rescued attachment pedal.jpg

I have a mini pedal box nor my new car. Sadly, the pedals are too far apart. Each pedal has 2 20° bends in the metal making them 135mm between

centres. I want them to be 95mm apart.

I'm guessing that cutting and welding is not a good idea. What do you suggest?Image deleted by owner

why is the brake light switch on the clutch pedal ?

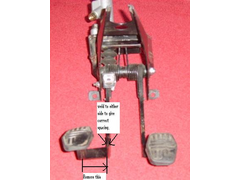

move the left hand pedal to the right by taking out the horizontal piece. You can weld the part with the rubber bit on to the vertical pedal piece.

Here is a pic

Rescued attachment pedal.jpg

quote:

Originally posted by redscamp

why is the brake light switch on the clutch pedal ?

Welding is as OK as your welding capability

cut the pads off the ends (mini rubbers are no good)

mount drilled metal pedals offset

if done it by welding stainless to mild before!

quote:

Originally posted by smart51

Is a welded pedal safe / SVA friendly? I guess there's less load on a brake pedal than a suspension mount after all.

Thanks Guys. What I've done is cut a 3mm slot across the 6mm thick metal, so I can straighten the bends on the left hand pedal. I then welded up the slot. The left hand pedal is now straight. I'm happy with the weld penetration and in any case I didn't cut all the way through the metal.