whats't he best way to press bearings in?

blakep82 - 10/1/08 at 12:22 AM

i've got these type of bearings

http://www.fag.com/content.fag.de/en/ina_fag_products/productinformation/rotativ_products/cylindrical_roller_bearings/high_precision_cylro/hochgenauig

keits-zylro.jsp

meant to take some pics of the hubs while i was out there, but i forgot my phone.

whats the best way to put them in.

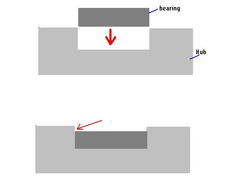

crap drawing

bearing

i thought they'd be easy enough, but was worried about damaging them. pressed one most of the way in using a vice and some peices of wood to stop

the jaws damaging it, but i can't get the seated as far in as they should be.

what to do?

oadamo - 10/1/08 at 01:08 AM

big socket and tap them in with a hammer.

adam

Mr Whippy - 10/1/08 at 01:17 AM

can you not find a socket to go on top?

I'd be weary of using a hammer on them but if you do make sure you use a drift, brass is best and spread the impact over as large an area as pos,

wheel bearings are easy damaged.

nitram38 - 10/1/08 at 05:45 AM

You can use a vice with the correct sized socket, but favourite is have a chat with someone with a bearing press.

It will not only make the job quick, but also ensures the bearing goes in straight.

RickRick - 10/1/08 at 07:43 AM

heat up the hub, that should help the bearing slide in.

flak monkey - 10/1/08 at 07:52 AM

You are fine tapping a bearing into a housing, as long as you hit on the outer race and not the inner, otherwise you will damage the track and

balls/rollers. The best way to help them in is to use a smear of bearing assembly paste, or thick grease. Not much though.

If you do hit it too hard you'll break the race, but it should never be that tight!

David

fatfranky - 10/1/08 at 08:19 AM

My personal favourite has always been to take the old knackered bearing and grind a small amount off the outside of it so that it is slightly

undersize and then use this to drive/press the new bearing in.

This ensures that you are pressing on the outer race and therefore not damaging the bearing and is also a nice square fit.

This assumes of course that you are replacing the bearing and not refitting the old one.

NigeEss - 10/1/08 at 08:36 AM

quote:

Originally posted by fatfranky

My personal favourite has always been to take the old knackered bearing and grind a small amount off the outside of it so that it is slightly

undersize and then use this to drive/press the new bearing in.

This ensures that you are pressing on the outer race and therefore not damaging the bearing and is also a nice square fit.

This assumes of course that you are replacing the bearing and not refitting the old one.

Much easier to slice it (old race) into a C shape with the wizzer than grinding all

round the outside.

Or as Flak says, tap it in. Go gently from one side to the other moving round as

required to keep it perpendicular.

[Edited on 10/1/08 by NigeEss]

blueshift - 10/1/08 at 09:15 AM

"wizzer", I like that

my angry grinder has a new name.

nige - 10/1/08 at 09:35 AM

please

"DON,T USE A BRASS DRIFT"

brass splinters

copper is much better

or as above , old race or socket

pressed in a vice

Johnmor - 10/1/08 at 09:35 AM

The best way is to use a socket slightly smaller than the outer race and a bearing press/ or a large vice

I made a press using some 40mm box section and an 8 ton hyrdaulic jack, just have the jack sitting the right way up instead of mounted in the top

rail.

Only cost me around £30 for the stuff and its been one of the best 30 I've spent.

The danger of hammering is you send a shock throught the bearing and dislodge the ball bearings out of the plastic retainer in the inner race and end

up with a heap of bits rolling around the floor.

I have a 3/4 socket set and i've used it more for pressing bearings than undoing sockets

http://www.machinemart.co.uk/images/library/product/medium/02/020410030.jpg?

bassett - 10/1/08 at 04:40 PM

Could try putting the hub in the oven and the bearing in the freezer.

Adam

blakep82 - 10/1/08 at 06:27 PM

the bearing's 4" diameter (approx) and i don't have a socket that big

hub is alloy so i probably want to avoid heating it... bearing in the freezer though! I'll do that

one of them#s already half way in, so need a bit more work, but i'm gonna put the bearing in the freezer now so it'll work later