Any advice on how to seal it - eg some thingy tape or stud seal possibly

Paul

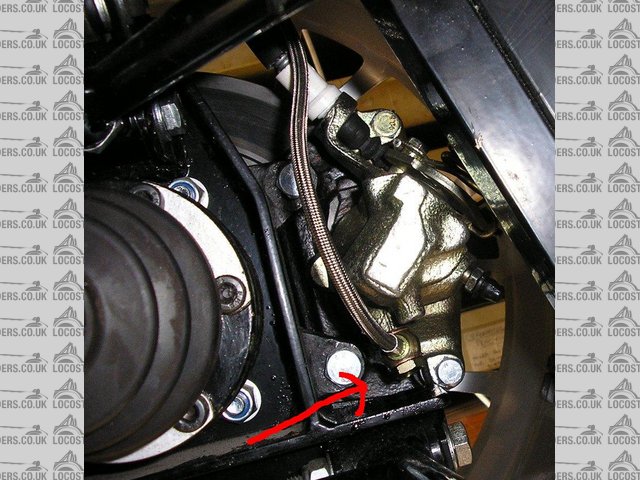

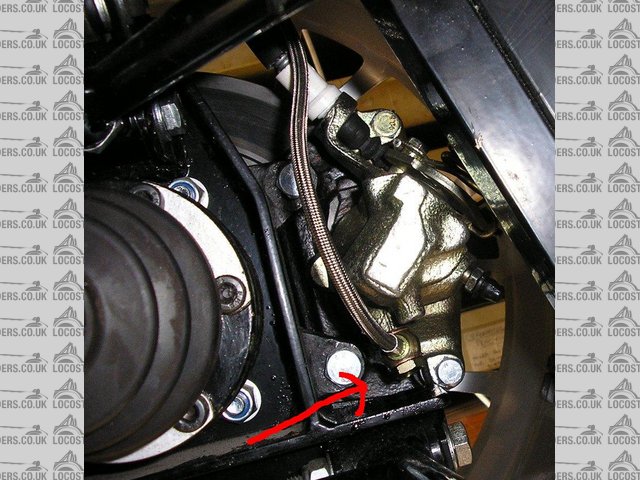

Rescued attachment nov0leak.jpg

The final thing to sort out on the car before I put in the SVA papers is a brake fluid leak on one of the rear callipers. I have fitted new copper

washers and banjo bolt but it still leaks.

Any advice on how to seal it - eg some thingy tape or stud seal possibly

Paul

Rescued attachment nov0leak.jpg

Sounds as if it is thread bound.

by that do you mean the threaded sectionis too long ?

I had the same problem today with my banjo clutch solved by using some PTFE type on the threads and tighten it very very tight!

Hope that sorts its...

ASAIK, they don't need to be that tight. If it's still leaking then it the bolt is too long or it's got dirt in it.

Check bolt length and thread condition, then mating surfaces.

Is PTFE tape brake fuid resistant?

ATB

Simon

I threw away the Banjo bolts that came with the hose kit after I got some shorter ones from Rally Design.

Had to get at least one new one when one of the original ones broke trying to tighten it.

The "is PTFE tape okay for brake circuit?" discussion has been had before.... I think the answer was its not best engineering practice as you shouldn't be getting spiral leakage if the threads are clean and the bolt isn't too long...

quote:

Originally posted by joolsmi16

I had the same problem today with my banjo clutch solved by using some PTFE type on the threads and tighten it very very tight!

Hope that sorts its...

Hi it's the flat faces that should be doing the sealing.

You will find that there is not a perfect flat face on the caliper where the copper washer sits against it. As the caliper was not originally

desighned to have this type of fitting connected to it.

Cheers Matt

as they say, the copper washer/flat faces do the sealing so ptfe should nopt be required.

youy can work out if it is thread bound by measuring the gap by doing up the bolt without the washer.

either fle down the bolt, get a shorter one of maybe use two copper washers.

each time you do up the bolt, anneal the washer - heat to red hot then drop into cold water.

quote:

Originally posted by 02GF74

each time you do up the bolt, anneal the washer - heat to red hot then drop into cold water.