PTFE tape

locoboy - 6/8/07 at 08:21 PM

Right,

SVA looming on the 9th, usual nut covers and trim to apply and thats about it ( he says confidently!)

I have a bit of a soft brake pedal and my brakes are pants.

I have a slight weep coming from my brake pressure switch on at the rear. Its fitted in a 4 way connector.

I have main front to rear coming intoo it, 2 flexis out for left anf right rear and spare hole that the pressure switch is in.

When i bought the switch it had a tapered thread, now does the hole i screw it into have to have a corresponding tapered thread or should it have a

paralell (non tapered) thread?

I have it tightened up as much as i dare at the moment.

If what i have is compatible would PTFE stop the weep and is it brake fluid proof?

Thanks Mr. Panic

Peteff - 6/8/07 at 08:34 PM

Unless you have imperial fittings you should have M10 switch which is not tapered

NFauto sell them for £6 +p&p but you could get one cheaper from a local parts shop Look down

the page

[Edited on 6/8/07 by Peteff]

BenB - 6/8/07 at 08:34 PM

If IIRC NTP and BSP are the same but one is tapered and one isn't.....

PTFE tape will take up the slack and is brake fluid AOkay....

owelly - 6/8/07 at 09:08 PM

NPT and BSP are not the same and are not compatable.

BSPT is tapered. Usually the female part of a BSP thread is parrallel.

I doubt very much that you have BSP on your brakes. You'll likely have metric. I would strongly advise against using any thread sealer, tape or

compoun on your brakes. There is a reason why you have a leak and that needs to be addressed.

BenB - 6/8/07 at 09:51 PM

I've read (on quite a few sites) that below 2" the differences are so small that they're interchangeable.....

[Edited on 6/8/07 by BenB]

[Edited on 6/8/07 by BenB]

RazMan - 6/8/07 at 09:52 PM

A drop of Loctite Thread Seal is easier

BenB - 6/8/07 at 09:54 PM

http://www.spartan-pd.com/PDFfiles/NPT-BSP%20Article.pdf

respectfully

Mind you, the switch is probably metric!!!!!

owelly - 6/8/07 at 10:29 PM

I stand by what I said. The TPI is the same on 1/2" and 3/4" bsp/npt but the thread angle is different. They are not interchangable. And

I'd be suprised if anyone has 1/2" brake fittings.

If you start fitting the wrong threads, you will start to distort/damage the threads which weakens the joint. There is a tendancy to overtighten

leaking joints but obviously, this compounds the problem by further distorting things. It's also very easy to make a fitting oval by hamfisted

use of and open-ended spanner or stilsens. This also promote leaking so folks try to tighten it more.....

I say this as an experienced engineer with many hours trying to fixed other peoples attempts at screwing BSP fittings into NPT 'oles and

vice-versa. It is possible to use some metric gear in whitworth threads if you try hard enough but it's still not right.

caber - 6/8/07 at 11:10 PM

If it is noticed PTFE tape on brakes is an MOT fail. Also a fail on power steering.

Caber

locoboy - 7/8/07 at 06:28 AM

so a non tapered metric switch and a non tapered metric 4 way union is the way out then?

I will have to see what i can get today, i know my local factors dont sell braking components any more beacause of fear of litigation!

britishtrident - 7/8/07 at 06:55 AM

You may find it is UNF thread, some Lucas pattern switches require the use of a copper or soft alloy washer to seal.

locoboy - 7/8/07 at 10:02 AM

I have metric flexis coming into and out of it too though so surely i cant screw a UNF switch into a metric housing can i?

Im beginning to fret now as if i want to order anything i need to do it today as none of my local factors hold 4 way unions.

and amy SVA is on Thursday!

locoboy - 7/8/07 at 10:19 AM

No where seems to do the 4 way unions, not even the hydraulic specialists!

Ened up ordering one from NF as peteff posted.

Its in the hands of Royal Fail now, post 1st class today and fingers crossed it will be delivered tomorrow!

907 - 7/8/07 at 10:30 AM

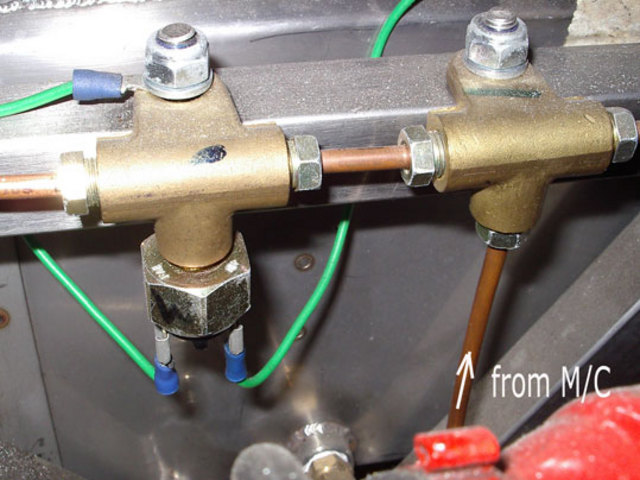

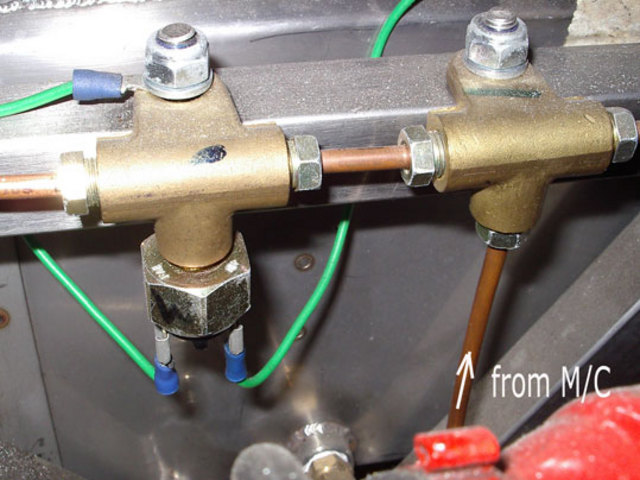

Instead of a 4 way could you use 2 tees?

They are easier to obtain.

I have one tee to split the pipe left and right, and a second in the line to screw the pressure switch in.

It may be a quicker option.

Paul G

locoboy - 7/8/07 at 10:46 AM

that means chuffing about removing the brake line from the p clips and cutting it then trying to get the flaring tool into the small gap to flare 2

new ends for an aditional T.

Also the more joints i have the more likely it is to leak!

I WILL do it differntly next time!

NS Dev - 7/8/07 at 12:09 PM

as 907 says, use two 3 way unions, no problem, just leave the existing pipe as it is, but bend it a bit and introduce as short a bit as your flaring

tool will allow, plus the extra tee piece, jobs a goodun

[Edited on 7/8/07 by NS Dev]

907 - 7/8/07 at 01:36 PM

Using tees has the advantage of being able to face the switch downwards and eliminate the air pocket as well.

Sorry for the dusty pic.

Paul G

Rescued attachment brake-tees-003-s.jpg

bobster - 7/8/07 at 02:05 PM

i have a spare 4 way with brake switch already seated in. if you pm me your address or phone I can send it out in the post for you to hopefully arrive

tomorrow. if that's any use to you?

bobster

locoboy - 7/8/07 at 04:11 PM

Bobster u have U2U if not too late

Thanks

BenB - 7/8/07 at 06:14 PM

quote:

Originally posted by owelly

I stand by what I said. The TPI is the same on 1/2" and 3/4" bsp/npt but the thread angle is different. They are not interchangable. And

I'd be suprised if anyone has 1/2" brake fittings.

If you start fitting the wrong threads, you will start to distort/damage the threads which weakens the joint. There is a tendancy to overtighten

leaking joints but obviously, this compounds the problem by further distorting things. It's also very easy to make a fitting oval by hamfisted

use of and open-ended spanner or stilsens. This also promote leaking so folks try to tighten it more.....

I say this as an experienced engineer with many hours trying to fixed other peoples attempts at screwing BSP fittings into NPT 'oles and

vice-versa. It is possible to use some metric gear in whitworth threads if you try hard enough but it's still not right.

I wasn't suggesting putting BSP into NPT was always a perfect engineering idea and it's true that threads that are close but not quite the

same can cause no end of problems.... Especially when people think that a bigger spanner and more torque is the answer to everything...

However, it's also true that the main difference between a BSP and NTP is the thread angle, so they'll interlock even if only at a reduced

number of thread sites. However, the slight gaping due to the difference in thread angle will lead to spiral leaks unless blocked with something like

PTFE tape.

Certainly for low pressure pipes a PTFEd BSP / NTP interface would seem a fine (to me at least) if admittidly not very elegant solution. For high

pressure stuff like brakes it's probably not a good idea, especially when the possible ramifications of failure could be so bad....

So I suppose I'm coming at it from a point of view that on occasion BSP and NTP can be interchangeable (as in its a useful thing to know to be

used sensibly and on a case by case basis). You're coming at it (as you state) from a point of view of mending mistakes when people have used it

not so sensibly!!!

I guess its the same truth from different points of views

I still reckon the thread is metric though

NS Dev - 7/8/07 at 06:33 PM

I've never had an issue with interchanging bsp and npt, but I've only ever done it on 1/8", as I suspect is the same with most on here.

owelly - 7/8/07 at 08:08 PM

With coolant and lube oil systems the worst that can happen is you have a leak. Perhaps enough of a leak to damage something. With brakes, you coud

have a big whoops and kill a school full of children. Possibly.

The point I was trying to make was that the threads are different. It's up to each individual to decide if it's worth 'making do'.

You can screw a 1/8bspt sender into a npt hole but if the sender shears off when your trying to put it in, or more likely, when you're taking it

out, then so be it.

I shouldn't be preaching such things as I did graunch a bsp sender into a npt hole just the other day but in my defence, it was late, I was tired

and I wanted to hear the engine run.....

locoboy - 7/8/07 at 11:51 PM

Right,

I took the swithc out and the thread on it was fine, i then tried to screw in a standard M10x1 brake fitting and it went in by hand no problem so the

thread in the 4 way was fine too.

I pulled a copper washer out the bin that had been on another random brake flexi i had lying about and put 1 wrap of PTFE round the thread and popped

it in by hand and niped it up.

So far it seems ok, no visible fluid leak as yet, will check in the morning and report back!

Pedal felt a lot better too.

FIngers crossed

ironside - 8/8/07 at 01:23 AM

This may be too late, but MNR do 4 way unions.

locoboy - 8/8/07 at 08:20 AM

Pedal still feels ok, its hard to tell whats an acceptable pedal when you have not driven a seven for 3 years!

It does not seem as firm as last night but i will re bleed again tonight in preperation for tomorrow.

no visible fluid loss though

Just got to try and set up the speedohealer tonight, oh joy!

NS Dev - 8/8/07 at 12:52 PM

when bleeding its worth cracking the switch loose and bleeding some fluid out from it as they tend to get an air bubble in them that doesn't help

pedal travel.

locoboy - 10/8/07 at 06:25 AM

Well my 'pants' brakes scored an impressive 90+% at sva.

Just goes to show how diluted the feelings you get through your tin top brakes really are!