If yes to the tube ends, should these be flattened or should a small fillet be welded in, or again, does it matter?

Cheers

Alex

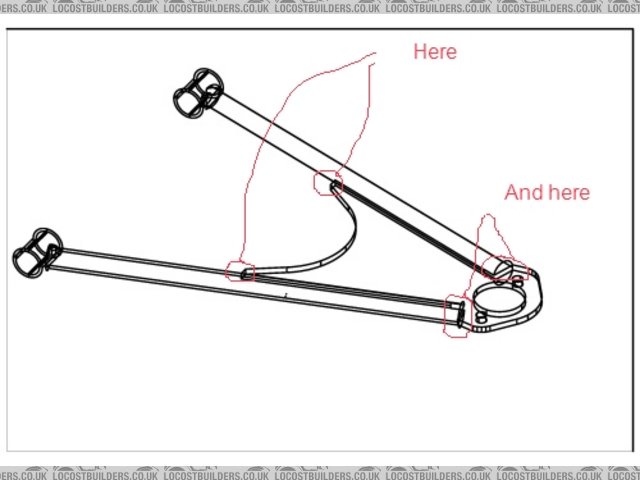

Rescued attachment bottomwishbonetest.jpg

As per pic below, I'm not sure whether I should weld up the end of the tubes where they finish at the BJ end and on the small vertical face of

the plate to tube area, does it matter or make a difference to the strength of the part?

If yes to the tube ends, should these be flattened or should a small fillet be welded in, or again, does it matter?

Cheers

Alex

Rescued attachment bottomwishbonetest.jpg

The one shown in your diagram looks very similar to the lower front MK wishbone for the Indy. On the MK supplied item the plate si fully welded to

the tube and the ends of the tube are closed with a weld bead.

HTH

I'm going to weld it.

I had the same thoughts.

But as the weld isn't around the tube it will no or less influence to the strenght

The front of the tube will be in my case will be inserted by the mountingplate.

I don't want any water or something else into the tube so i'm welding it.

grtz

Hi

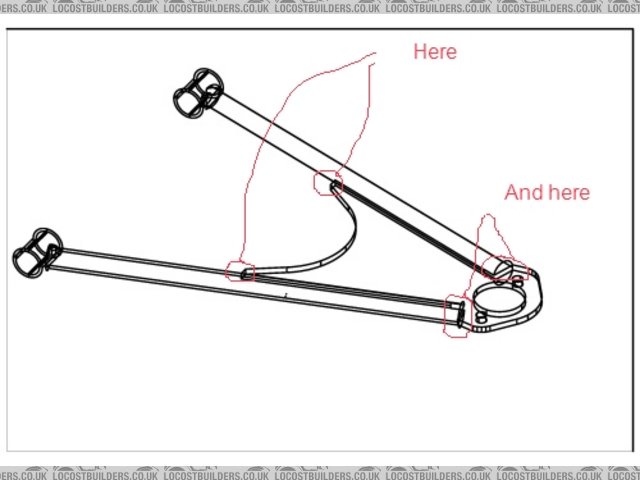

I welded round the ends of the gusset plate and cut half circles and welded in at 45deg. (see pic.)

HTH

Paul G

Rescued attachment w b tube end s.jpg

Thanks guys  , weld it is then (hadn't thought about water getting in

, weld it is then (hadn't thought about water getting in  ) and the 45deg angle and fill method looks good.

) and the 45deg angle and fill method looks good.

Cheers

Alex

when you finish the welds at the inner end (plate to tube) run them out away from the joint and onto the tube a bit.

Prob ott on this application but always good practice to run the weld out a bit to move the end of the heat affected zone away from the point of peak

stress. (have a look at a JCB digger's rear arm next time you get the chance, look at the flange plates on them and how they fork out the welds

from the ends of the plate onto the boom to prevent cracking)

[Edited on 30/11/06 by NS Dev]

quote:

Originally posted by NS Dev(have a look at a JCB digger's rear arm next time you get the chance, look at the flange plates on them and how they fork out the welds from the ends of the plate onto the boom to prevent cracking)

[Edited on 30/11/06 by NS Dev]