I'm very interested!!

Stubs are avaialble off the shelf in threaded from from several suppliers, Randall Motorsport do them for £23.50 each

Can any one design an ally upright

I am a pattern maker by trade and are willing

to model in cad and cnc the patterns free of charge.I can also get them cast at a local foundry in LM25(at a cost),but will need help for maching

them.

I also need a supplier for the stub axels.

Any one out there interested

lm25; isnt that what k series blocks are made from

What sort of cost for casting them?

I'm very interested!!

Stubs are avaialble off the shelf in threaded from from several suppliers, Randall Motorsport do them for £23.50 each

The price will be between 12 and 15 pounds

per kilo,so it all depends on the design of the upright.They will also need heat treating I dont

now the price for this at present but the more

the cheaper

The thread on ali uprights on the MNR section is deleted. Pity.

Ali uprights, properly designed for impact and longevity in mind, and age hardening crystallisation, will end up near as heavy as Cortina items.

Much better to make your design and patterns for steel. Ends up lighter if properly done, and with none of the fatigue issues of aluminium.

Cheers,

Syd.

have a look at lotus elise uprights, they are aluminium, I reckon they are cnc milled rather than cast though. I'd have a go at the design if you

get stuck, but I am a product designer rather than an engineer. Anyway let me know if you want me involved.

Cheers.

Steven

rorty did cad designs of sierra uprights (same as cortina) to be made up as jigsaw puzzles. i think he was giving the cad drawings free so id check his posts or do a search for uprights. they werent corrected geometry or anyhing though, he will design a better geometry front end for use with vw golf parts, but needs people to size the parts. look on 'new locost front end' on the left hand side of the main screen, about 3rd under longest running threads.

nealg

You have U2U

quote:

Originally posted by Hammerhead

have a look at lotus elise uprights, they are aluminium,

I know over time aluminium alloys can become fragile but what about if they have been hard anodised?

See here

"The hardcoat layer is equivalent to one of the hardest materials on earth: ruby"

I've also read that the hardcoat process can make the alloy as hard as steel. Would this not negate the usual fracture issues associated with

untreated alloy?

Also see here

Also if the uprights are CNC'd from solid billet of a good strong alloy (6082) to begin with, would this also increase the robustness?

I think the coating process is just that, more of a wear resistance thing. It won' remove the fracture issue, which would start to occur in the centre, if I remember how it works right.

Hardness is not the same as fatigue resistance. They could be as hard as you like but still crack due to age.

I'm using C5 Corvette uprights, they can be had on eBay for ~$100 a pop. There's only 2 types the front left is also the rear right and

vis-versa

These are forged alloy with a bolt in bearing - stub axle sub assembly (this comes as one lump when replaced)

Without the bearing they weigh 2.2kg (includes top ball joint) and with the wheel bearing they are 6.6kg a throw. How does that compare against a

Cortina or Granada upright?

The bearing / stub axle assemblies can be had as Timken parts for ~$170 each either front or rear and come with the ABS sensor.

I have no doubt that these are strong enough for the job.

I guess I've got 2 points here...

1. Theres strong production alloy parts available that don't cost a fortune.

2. Because of the web and eBay you can look further afield than the local wreckers / breakers for interesting items.

BTW 'Billet' means a big lump of metal 'Machined from billet' means machined from a big lump of metal. It means absolutely

nothing in terms of the strength of the part.

for large machined alloy parts in the aircraft business they will often machine off the outside 1" or so all around a billet simply because the

strength / grain structure is not consistent across the part due to the way the grains form in the material as it cools.

Most all of the serious high strength requirement alloy parts on aircraft are forged wherever possible.

None of which answers the original question, One way to go might be to look for parts of similar construction that you intend that are known to be

able to take a beating. The Corvette may be one place to look, or possibly something low production like a 6R4 metro, RS200 Escort, TVR or DeTomasso

(I'm guessing here) where there mightn't have been the quantity made to warrant forging.

Doug.

Hmmm...here's one of those c5 uprights (for reference):

http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=320049510986

Here's another:

http://cgi.ebay.com/ebaymotors/97-04-c5-corvette-spindle-right-front_W0QQitemZ180051380879QQihZ008QQcategoryZ6763QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

They look pretty nice. Dont think they would work w/ my suspension geomety, tho. The steering arm looks about 2/5's of the way up the spindle,

whereas sierra ones are about 1/5 of the way up (atleast my raceleda based sierra ones are). So, i would have to move the steering rack

substantially!

-Scot

[Edited on 20/11/06 by scotmac]

RE: elise uprights

If I remember correctly they are made from extruded sections similar to the chassis rails.

Yes the early alloy uprights should be reinforced if used on track with semi or full slick tyres. The lower track rod mounting point fractures. The

later steel uprights are stronger and lighter!

quote:

Originally posted by bimbleuk

The later steel uprights are stronger and lighter!

The forged steel upright is a much stronger and more rigid unit, but not lighter. They are 3,5 lbs heavier than the aluminium ones (total for 4

uprights).

More detailed info can be found in the following PDF (from page 11 on).

ELise Upright

[Edited on 21/11/06 by Lippoman]

[Edited on 21/11/06 by Lippoman]

Well,Well, Well,

Halelujah Lord! At last someone has finally seen the light and decided that lightweight aluminium uprights are not suited for everyday road use!

And the mighty Lotus company at that!

They wouldn't have switched from Ali to steel for no good reason.

Cheers,

Syd.

It costs 30% less than the aluminium one, that's why they changed.  The aluminium looks more trick though and doesn't need painting so it

doesn't matter if it's you're going to die horribly in a mass of twisted metal as long as your cred stays high.

The aluminium looks more trick though and doesn't need painting so it

doesn't matter if it's you're going to die horribly in a mass of twisted metal as long as your cred stays high.

quote:

Originally posted by Peteff

It costs 30% less than the aluminium one, that's why they changed.

University learnings for make education of glorious community of Locost Builder...

http://www.forging.org/members/docs/pdf/FIERF-AISIFinalExecutiveSummarySept04.pdf

Not really a fair test given the sponsor of the work and selection of test parts but intersting non the less.

with lots of people considering the use of Rorty's IRS had you considered making an equivalent rear upright. I am sure I'm not the onlyone who might be interested.

If someone will design a rear upright I will

cut the patterns at work but its the actual

machining of the cast uprights which I can not do

The main reason why I started the thread is

I am starting to design a 3 wheeler similar to

the vw gx3 so if there any designers out there

who can design some sort of rear hub assembly similar to the ducati 916 to hold a 18x9 wheel on a single sided swingarm let me know

Thanks

quote:

Originally posted by Doug68

University learnings for make education of glorious community of Locost Builder...

http://www.forging.org/members/docs/pdf/FIERF-AISIFinalExecutiveSummarySept04.pdf

Not really a fair test given the sponsor of the work and selection of test parts but intersting non the less.

No, not as simple as that I'm afraid!

Depends on what jointing processes are used, application, fatigue requirements etc etc etc.

benefits over a well designed steel structure are very minimal. The main problem with steel is using a small enough section to optimise the stresses

in it, sometimes needs an unfeasibly small sectional area to allow for jointing etc, in just the same way as ally can be extremely strong, but when

that alloy is welded it will fall apart! (in simple terms! )

Some aluminiums are very strong indeed, but are not weldable (many aluminium alloys infact cannot be welded!).

Some alumnium can be heat treated and hardened by solution hardening, and some of these alloys are also weldable. However, they need to be retreated

after welding!

Designing in aluminium is different to designing with steel. You have to worry about fatigue in everythig you design in ali, also in general ali is 3x

lighter and also 3x less stiff than steel, so the actual fundamental design considerations are completely different if you want a stiff ali structure.

The rule of thumb I was thaught is that Al is 1/3 the strength and 1/3 the weight of steel.

So, theoretically, a skinned honeycomb panel could be as light and as stiff if steel 1/3 of the thickness was used as compared to Al, but it would be

much more sensitive to deformation in the skin as the section of the skin itself would be so thin.

(Moment of inertia is cubed by the thickness of section.(simplification))

This is one of the reasons why you can create parts that are stronger in Al compared by weight to steel, especially in parts where expected life is

limited. Add fatigue into the equation and you've opened a new can of worms...

So for the same strength you would need 3 times as much material which would bring you back up to the same weight and cost you how much more as well?

This seems like an exercise in futility as the whole idea in the first place is to save weight isn't it? Stick to using aluminium for the

bodywork and wheels I think is the message.

quote:I've seen aluminium and carbon frame bicycles break but all the steel ones I've seen in similar cases have bent, admitted they are lighter in other materials but you can straighten the steel and don't need to replace or tig to repair. F1 will have a limited life expectancy anyway so they are not really relevant as they are only engineered to do the job for a season at most, not to last for years.

both F1 and bicycles used aluminium for this exact reason, before switching to carbon fiber.

strong Al alloys can be welded the Fox armoured car is made from Al armour plate. Many years ago I used to examine the welders test pieces. These were

14 run welds and were only allowd 1 inclusion or void per half meter length of plate.

Much Much Respect

Loads may buckle very thin steel, so using 2 times thicker Al there increases the stiffness 2,6x while still having a weight of 0,67x...

It is still weaker than the steel in tension but "stronger" in compression as it doesn't buckle. This is especially important in the

web of beams or in skins...

Manufacturing issues (especially in casting) may also make the Al version much lighter, you simply cannot always create steel parts as thin as needed

to make them lighter than the Al parts that are strong enough.

Chosing the correct material is much more than just looking at the strength in material specifications, you have to factor in manufacturing, design

and all the loads the part will encounter. Also the fail mode is important, it is often preferrable that the part yields rather than breaking of

suddenly...

And as I've put far too may times, the problem with ali castings is crystallisation, and designing for proper cyclical fatigue loading problems.

Proper heat treatment is all important, and many small manufacturers seem to omit this vital part of the process, or shortcut it.

Failure mode is critical.

To be safe, an ali part for an upright will be as heavy as a properly designed steel item.

I've seen the result of this type of design far too often. The parts I deal with in my work are lifed. On gravel roads this can as little as

50~80kms!! If things are really rough, steel is the material of choice every time, to avoid failures.

Cheers,

Syd.

So there is mass discussion about materials. I will offer some input on the actual design.

For a front upright I prefer to see automotive balljoints used. It is difficult to get reasonable suspension travel and steering lock with spherical

bearings. Plus quality bearings will cost at least £30 each.

The same upright will be used on the left and right. The steering arm will bolt on and be a double shear arrangement to take a spherical bearing as a

track rod end. Or you could bolt on a steering arm that uses an automotive track rod end. a bolt on arm gives you the choice.

A standard centre section is required but the upper and lower should be easy to alter so you can optimise the ball joint position for different

suspension designs.

I am unsure if a live stub (as in Sierra) or a dead stub (like Escort) is preferential. With a live stub machining accuracy of the upright is

critical. With a bolt in stub you do not have to be so critical on the machining of the upright. Regarding structural considerations perhaps somebody

else can advise.

Rear upright design can wait until another time!

John

quote:Can you explain how you would make it double shear please?

Originally posted by JB

The steering arm will... be a double shear arrangement

quote:How would you allow the positions to be adjusted if not part of the machined whole? Bolt on in some way as the steering arm?

A standard centre section is required but the upper and lower should be easy to alter so you can optimise the ball joint position for different suspension designs.

quote:Can you explain the differences?

live stub (as in Sierra) or a dead stub (like Escort)

You can get much better geometry with the 'live' stub axle. As in the Sierra.

Live stub certainly gives you the choice to put things where you want them, and if making uprights with thread-in stubs anyway, the live stub is no

harder to make either.

PS to answer the question about what is the difference, live stub is where the stub is "with" the hub and rotates with the wheel in bearings

in the hub carrier like on the sierra design. Dead stub is where the stub is fixed to the carrier and the hub rotates on it like the cortina design.

quote:

Originally posted by JB

So there is mass discussion about materials. I will offer some input on the actual design.

For a front upright I prefer to see automotive balljoints used. It is difficult to get reasonable suspension travel and steering lock with spherical bearings. Plus quality bearings will cost at least £30 each.

The same upright will be used on the left and right. The steering arm will bolt on and be a double shear arrangement to take a spherical bearing as a track rod end. Or you could bolt on a steering arm that uses an automotive track rod end. a bolt on arm gives you the choice.

A standard centre section is required but the upper and lower should be easy to alter so you can optimise the ball joint position for different suspension designs.

I am unsure if a live stub (as in Sierra) or a dead stub (like Escort) is preferential. With a live stub machining accuracy of the upright is critical. With a bolt in stub you do not have to be so critical on the machining of the upright. Regarding structural considerations perhaps somebody else can advise.

Rear upright design can wait until another time!

John

I've worked in foundries making valves for the oil industry and rotors for the power industry and anything you can cast in aluminium can be cast

in steel with a lot less waste and shrinkage, can you explain why the thickness (or thinness?) can't be achieved in steel? (Quote from

Lippoman)

[Edited on 27/11/06 by Peteff]

Ahh! wasn't specifically referring to uprights, and WAS referring to a DIY situation.

What I meant was that in a lot of cases, steel parts are only heavy because they were vastly overspecced for the job, largely because the steel that

was available was too thick for the job.

For example, think of making a steel bike frame. The amount of steel actually required to perform the job is TINY, but physically forming tube thin

enough is very expensive, so heavier tube is used, then people say it is heavier than aluminium. Practicality of manufacture comes into this argument

a lot more than people will acknowledge!

To make a steering arm double shear you use 2 plates. This could be a bolt on “U” shape that goes on the front or back side of the upright. Or 2

plates that go across the back of the upright. As in the picture of my car.

(I know it needs a clean but I was too busy driving it and I will clean it over Christmas)

The advantage of these double shear plates is that it is easy to alter the ackerman and or steering ratio and they are structurally more efficient

than single shear.

This upright uses a push in lower ball joint and Jag upper ball joint. Apart from the hassle I had getting the steering arm on they are OK.

quote:

"A standard centre section is required but the upper and lower should be easy to alter so you can optimise the ball joint position for different

suspension designs.

How would you allow the positions to be adjusted if not part of the machined whole? Bolt on in some way as the steering arm? "

This is where it does get more difficult. If it is a steel fabrication then you just alter the size of the patterns you use to cut the steel. On a

casting you could have a pattern in 3 pieces, a standard centre section then various top and bottom parts. You could use bolt on parts but then you

are making it structurally less efficient.

John

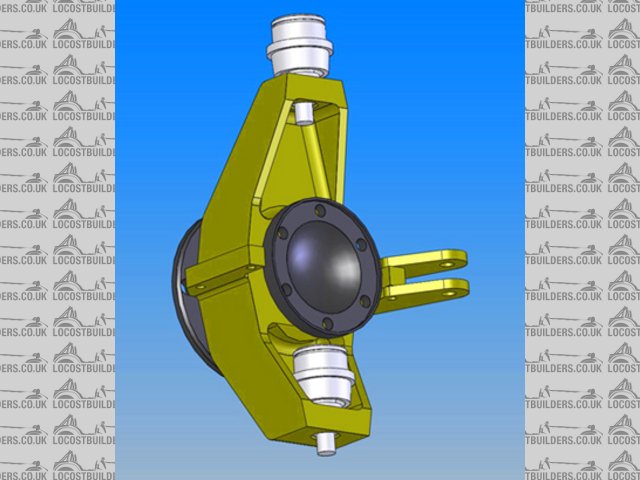

would something like this be suitable as

used on the dp1 car but using a fixed stub axel

Rescued attachment dp1_upright.jpg

If cast to the same dimensions (same mold) the Al part will be 1/3 the weight of the steel part. So every section you have to make thicker due to

casting or mold making reasons than needed for mechanical strength/stiffness will make the Al part lighter in comparison.

Weaker, but lighter.

quote:

Originally posted by dnmalc

strong Al alloys can be welded the Fox armoured car is made from Al armour plate. Many years ago I used to examine the welders test pieces. These were 14 run welds and were only allowd 1 inclusion or void per half meter length of plate.

Much Much Respect

Which cast aluminium alloy/steel are you referring to?

6000 series or 7000 series...eg, 6061-t6 used extensively in bicycle frames.