I believe the Sierra and Escort Mk5 1.4l use a servo dual cylinder without ABS.

Thing is, I clearly remember both the Sierra master cylinder and Escort Mk2 donor had one each BUT I binned them, Doh

Due to a recent operation I now have a weak ankle and need to change my brake bias bar setup for a servoed system.

I believe the BMW 3 series uses a twin circuit servo. Anyone have any info?

Anyone know of another twin circuit servo that's fitted to a car?

Is this what you are looking for. Scroll down to servo. It says they are bendix units. Have you searched brakesint?

http://www.ebspares.co.uk/news49.htm

Had a search but not found anything suitable.

I believe the Sierra and Escort Mk5 1.4l use a servo dual cylinder without ABS.

Thing is, I clearly remember both the Sierra master cylinder and Escort Mk2 donor had one each BUT I binned them, Doh

Actually Alfas used 2 single circuit Lockheed servos --- same design as fitted to Hillman Hunters, single circuit MGBs, some Vauxhalls.

The servo in the picture is a single circuit Lockheed design although it may have been manufactured by bendix.

If you can get a couple of Hillman Hunter servos they are very easy to rebuild --- and very reliable.

Nearly all cars these days use servos mounted between the pedal and the mastercylinders -- fitting a full size one into Locost would be a tight squeeze, it might be possible to use one from a Micra/Polo sized vehicle as these tend to be smaller than the Sierra/Escort sized servos.

quote:

Originally posted by Rob Lane

I believe the BMW 3 series uses a twin circuit servo. Anyone have any info?

Hiya Dick,

Short version. 25 years ago bad car accident, broken legs, ankle, no kneecaps.

Right ankle now worn down to bone, operation to fit screwed metal plate and lock ankle. Pot 14 weeks, removed Xmas week, now getting better but weak

ankle for a year or so.

Servo

I realise now I had misnamed it. I see its servo then M/C. That's just like the Sierra one I had.

I'm doing a few mods now I'm mobile again and one is to change the brakes.

I have 4 pots fitted with twin M/C plus bias bar. Unfortunately although I can brake, an emergency stop would be extremely painful, assuming I could

generate enough force.

Rob

Would your best option (this may be what you meant anyway!) not be to use a pair of remote servos and keep your bias bar? (or just servo the front,

but that might mean you run out of travel on the balance bar trying to get enough on the no-servo rear brakes.

I'd certainly look at doing it that way. BMW's, but I can't remember which models, had these dual circuit remote servos, it's a

common conversion used on Opel Mantas in order to ditch the std servo which gets in the way when fitting twin weber carbs or throttle bodies.

I would imagine that if you have the battery on the bulkhead panel at the moment, you could move this to the front of the passenger footwell and mount

the remote servo/servos on the bulkhead.

Just a possible solution.....

If its 0.7" dia master cylinders you are using in your existing pedal box fitting 0.625" shoul reduce the pedal effort by 20%

Thinking about it I seem to remember early Mini Cooper S (the real ones) had a smaller version of the Lockheed servo it might be possible to get

two of those under a Locost bonnet

[Edited on 2/2/06 by britishtrident]

The Mini idea is interesting. I could fit that lower down the bulkhead and still use the floor mounted pedal with a bit of mod for the leverage.

I did notice a pic of one but discounted it due to being vertical, but now I think about it, it could be the solution.

E21 bmw,s had twin servo,s,doubt if you would find any around now,also fiat 131,s i belive.

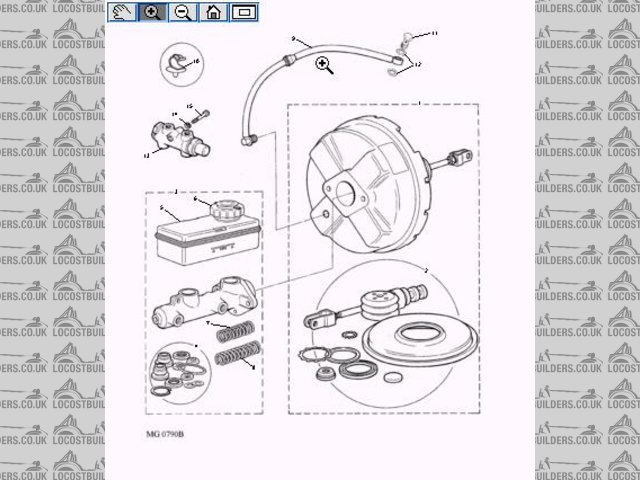

The later mini's had a horizontal servo and twin line cylinder, should be just the job. They're fairly small, and if even that's too

big, why not get a remote servo? Also fitted to the proper Cooper S's at some point. But don't go looking for anything Cooper, S or

otherwise, as it'll cost a fortune due to the name. Just look for a standard remote servo. Shouldn't be too much if buying new.

Hope all that helps

1990s Min Brake servo

Rescued attachment ScreenShot004.jpg

New 90's mini servos seem to run £120 ish new.

http://www.minispares.com/Product.aspx?pid=34058

as I said in my previous post, surely easier to keep the existing cylinders as they are, and fit a remote/pair of remote servo(s)

If you can't get a BMW E21 remote servo (thanks Conrodkid!!) then surely you can get an aftermarket one for this car.

I know car builder solutions do them but they are pricey, as do Europa.

Link to remote servo from Europa

as I say, not cheap but there must be alternative ones.

I think I posted this previously, or u2u'd someone about it.

Anyway, a remote setup can be made using most modern servos, by using a hydraulic clutch slave to actuate the servo, and use the standard master

cylinder on the pressure side, and plumb normally.

IE single m/c at pedal>clutch slave>pushes servo rod>pushes standard m/c of your choice>plumbed to your brakes. This system works with

vacuum or positive pressure in the diaphragm chamber. On opposite sides, obviously!

Seen it, done it more than once. Not on normal road cars though.

The only difference between this and the commercial remote servos, is that the commercials have the slave and master in one cylinder on the same side

of the vacuum chamber.

quote:

Originally posted by Syd Bridge

I think I posted this previously, or u2u'd someone about it.

Anyway, a remote setup can be made using most modern servos, by using a hydraulic clutch slave to actuate the servo, and use the standard master cylinder on the pressure side, and plumb normally.

IE single m/c at pedal>clutch slave>pushes servo rod>pushes standard m/c of your choice>plumbed to your brakes. This system works with vacuum or positive pressure in the diaphragm chamber. On opposite sides, obviously!

Seen it, done it more than once. Not on normal road cars though.

The only difference between this and the commercial remote servos, is that the commercials have the slave and master in one cylinder on the same side of the vacuum chamber.

Best to let Syd answer, but from my experience I can say that the std Mini slave cyl is the longest stroke and cheapest one available, hence why most use them!

I'll deal with this on a 1-1 basis with those wanting more help. (Far too many watching this forum endeavour to make commercial gain from what

is offerred freely here.)

To start with, put your lateral thinking hats on, and erase all of what you see under a bonnet from memory.  (Some are excused from reading further

at this point.

(Some are excused from reading further

at this point.  )

)

To explain the background thinking....The wife's Fiesta has the brake pedal on the RH side, but the servo/m-c is on the left, and they are

connected with a mechanical linkage. This is no more or less than a remote servo system, with a mechanical link.

When we first tried the remote thing at the workshop, it was attempted with a clutch cable and a lever assembly on the servo. So, a mechanical

connection using a cable. One more option.

The hydraulic setup was derived to cut down weight, and for spacial considerations. It is a remote setup, with a hydraulic connection.

So, three options for a remote with connections.

On the slave cylinder; I recall that the first used was from a european car, as the work is in France, but not sure. Anyone have any suggestions??

Further slaves were, and still are, made on a bespoke basis down in the workshop. Machined from barstock, reamed and honed, then put together with

industrial seals.

The early Mini clutch slave that I have is 7/8 bore, and so is the Sierra m-c that I have. So, they should be able to be made to work together, or

just use an aftermarket 7/8 m-c. There are a few nuances to be worked on those parts before the system is workable though.

Those wanting to take this further, u2u me please.

Syd.

A hydrualic connection would convert the system effectively into single circuit. Jaguar used just such a hybrid system in the 1960s on the E Type

using a bendix remote servo.

On the E type the Benix servo was operated by a single htydraulic circuit but the output was dual circuit --- bit of a bodge of a system.

A leak anywhere on the sytem would result total loss of fluid.

[Edited on 4/2/06 by britishtrident]

Trying to take over from that other fella, are you Trident? You show the limits of your understanding far too often.

Read what I put again, and you'll see that it is NOT a single system, but two very separate systems, separated by the servo. It can even

have dual m-c's on the output side of the servo, and an adjustable balance bar if sir desires!

The whole setup can utilise a single reservoir, and in the application where I see it used, it does. But with individual reservoirs, is no more

susceptible to fluid loss than any brake system in any car.

This setup is little different to what is found in larger commercials, with remote systems.

The system I outlined above is good enough to be used by a major manufacturer in its competition dept., for quite a while.

Maybe any detractors should broaden their personal databases.

Syd.

[Edited on 4/2/06 by Syd Bridge]

Can anyone suggest a single master cylinder to get the ball rolling?

Cheers

Chris

Edit:

Looking on ebay, would a Triumph spitfire/tr6/7/landrover one be suitable?

If so then as I understand it I'd need A triumph M/C attached to the pedal>a mini clutch slave cylinder > servo>M/C

can anyone suggeast a compact servo and M/C?

[Edited on 4/2/06 by chrisg]

quote:

Originally posted by Syd Bridge

Trying to take over from that other fella, are you Trident? You show the limits of your understanding far too often.

Read what I put again, and you'll see that it is NOT a single system, but two very separate systems, separated by the servo. It can even have dual m-c's on the output side of the servo, and an adjustable balance bar if sir desires!

The whole setup can utilise a single reservoir, and in the application where I see it used, it does. But with individual reservoirs, is no more susceptible to fluid loss than any brake system in any car.

This setup is little different to what is found in larger commercials, with remote systems.

The system I outlined above is good enough to be used by a major manufacturer in its competition dept., for quite a while.

Maybe any detractors should broaden their personal databases.

Syd.

[Edited on 4/2/06 by Syd Bridge]

The system I describe is versatile, and can be made 'Locost' at a fraction of the cost of commercial units, and maybe even with Sierra parts

to hand, plus a Mini slave.

Not reinventing the wheel, just giving it a different centre pattern.

I've got the bits in my workshop NOW to make one of these, and so have many on this forum. How many early Cooper 's' servos are there

floating about? And how much would they fetch these days?

Syd.

My detractors are mostly people who lack the ability to think laterally, they only see what they know or is directly in front of them. How many would

attempt to make a remote servo this way, when nothing else was on hand to fit? Same with most things people want to argue about. They'd all die

in the bush, when a bit of intuitive 'bush engineering' would save their lives. I've been brought up to think 'outside of the

envelope' as the yanks say. Intimidates some, because of some of the solutions that come out. Then again, my per diem is more than what most

earn in a week, and is that way because of the difference in the way I think, as most would be aware of by now. Crazy, insane, ....intuitive?? Call it

what you want. To me it's simple problem solving with a shoestring budget or limited resources. Or making something to fit a purpose when a

ready made is just not available. I've been down this road on here before, and won't go there again. Think laterally.

[Edited on 4/2/06 by Syd Bridge]

To reiterate my point for the third time (maybe eventually somebody will listen!!)

Keep the twin master cyls!!!

Servo the front circuit, don't servo the back. You can still balance the brakes with the balance bar, it will just be wound more to the rear, as

long as you are using equal front and rear cyls (prob 5/8" for both)

Use a remote servo of the various types described by Syd Bridge on the front circuit.

Job done.

Syd,

I see your point about mechanical linkage, yes I've owned a Fezzy with just same system, worked well.

I also see tridents view regarding a 'single circuit'. With a single line to the slave cylinder you are going back to a single circuit.

Should the slave fail ALL braking effort is lost unlike a dual circuit cylinder directly operated.

I'm sure a savvy SVA examiner would see this as single circuit brakes.

I like the look of the Mini horizontal M/C.

I don't really want to do any of this but it's forced upon me if I want to be able to stop

NS Dev,

We're all looking but just not answering

Rob

Hicost,

found it ! Anthony Stafford Vehicle Components at £245inc.

Could you send me pics of your install to give me some idea of size ?

rob@robs7.com

Rob

Rob,

Have you got top or floor hung pedals?

My brother in Aus uses a standard servo bolted onto the bulkhead, with a floor pivot pedal assembly.

A simple way out of this mess?

Regards,

Syd.

Hi Syd,

Floor mounted twin bias bar setup.

Fabrication's not a problem but I just hadn't paid much attention to servos before.

I need a size comparison first just to see what would fit.

Unfortunately just like everywhere else it's getting harder to be able to wander around breakers.

I think the bulkhead has plenty of room for a small servo.

Rob

Hi Rob,

Do you remember Rolands car - servoed Escort M/C.

Fits easily with a crossflow (don't know about Toyota).

Rather than use a bias bar, we used a hydraulic limiter for the rear circuit. This could be brought into the cockpit easily enough.

Floor mounted pedals too.

Marcus

Managed to get a Mini Cooper servo and all connection pipes from Ebay.

See what I can do when it arrives.

Thanks Marcus, I remember I had one once but dumped it.