Dem bones dem bones (comments please)

omega 24 v6 - 12/1/06 at 08:25 PM

I've just come in from making up a jig for my bones. I'm pretty happy with the idea althought it might need a little "je ne sais

quoi" before welding begins. Any comments ( sensible ) welcomed.

) welcomed.

Here's links to my archive why the hell can't I get the pictures to appear?

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=2wishbone2.JPG

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=2wishbone1.JPG

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=wishbone3.JPG

[Edited on 12/1/06 by omega 24 v6]

[Edited on 12/1/06 by omega 24 v6]

[Edited on 12/1/06 by omega 24 v6]

emsfactory - 12/1/06 at 09:07 PM

Is there enough clearance for the large balljoint bolts on the underside?

omega 24 v6 - 12/1/06 at 09:10 PM

It looks like it but I'll have to tack it all up and try first.

907 - 12/1/06 at 09:29 PM

Hi

The bend in the Cortina b/j is a pain.

I cut mine off and drilled two more holes, then mounted it from underneath.

IMHO the plate looks better if it's curved.

(Pic below)

ATB

Paul G

Rescued attachment bone-fitted-2-s.jpg

emsfactory - 12/1/06 at 09:30 PM

I only say as the bones I got in an abandoned project (they always seem so good at the time), made by a 'professional engineering firm'

welded the support piece on the edge of the bolt holes.

Pain in the yaris.

omega 24 v6 - 12/1/06 at 10:06 PM

Yep the bend is a pain and that's why I've put in the small vertical piece. Yhe bone plate will be curved for strenght/stress as well as

visual beauty. Where I'm not sure is should I weld both sides of the plate along the whole length?

The yellow item in one of the photo's is the hole saw I'll use in a pillar drill to curve the plate. But should i do it before or after the

weldings finished?

[Edited on 12/1/06 by omega 24 v6]

blueshift - 12/1/06 at 11:11 PM

you will need to secure the bones in a strong jig to stop them deforming a lot when you weld them. you may also want to use heat to stress-relieve

them before taking them out of the jig. I messed up my first bones not knowing these things, see my thread "warped me bones, fix or

cry?".

I cried.

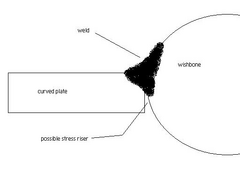

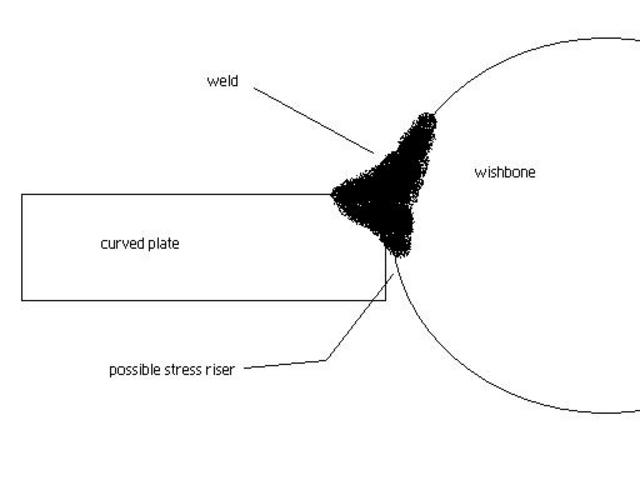

emsfactory - 14/1/06 at 04:01 PM

I wold do the plate curve before welding in. You can have them clamped flat on a block then.

Iwould weld both sides depending on penetration. If you dont have full penetration then you may be left with a stress riser.

Hope the crap drawing explains better.

Depends on your welder and plate thickness.

Rescued attachment weld.JPG

JoelP - 14/1/06 at 04:45 PM

the maxi balljoint would seem a lot easier to fabricate a wishbone around, is there a reason why so few people (myself included) use it?

) welcomed.

) welcomed.