Is this the right way to set up front suspension?

ditchlewis - 1/11/05 at 05:17 PM

I am just about to set up the front suspension on my car and just wanted to run my method past the experts first. May be there is an easier way?

I am using a sierra donor with the mushroom insert.

First I was going to jack up the front and using a “C” spanner to adjust the ride height, in creasing it about an inch.

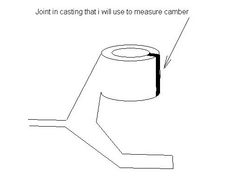

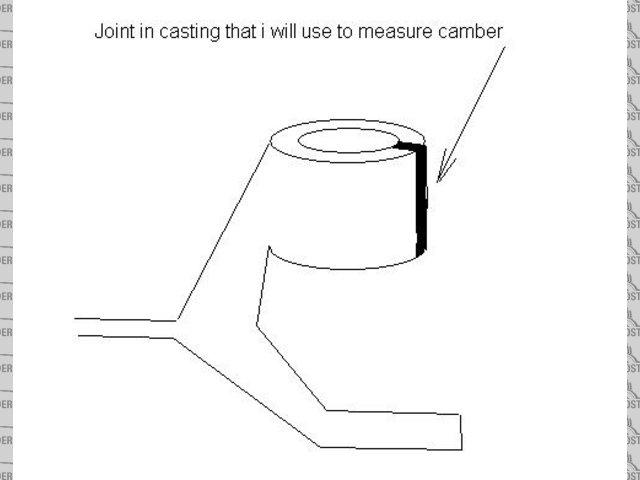

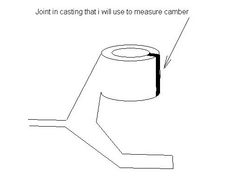

Then I was going to drop the car back onto it wheels and using the vertical split in the back of the upright and a 15cm length of timber measure how

many mm out of plum it is (6mm approx = 1degree).

I will than jack the car up and using the “C” spanner adjust the mushroom insert and replace the wheels.

Once the car has been dropped I will measure the difference between the top and bottom of the wheel and thus the camber. Removing the wheels again I

will then adjust the top ball joint to the required length to give 1 degree approx of camber.

The toe out will be set using the string method described in an earlier thread.

Is this the right sequence and method or have I got it all wrong?

Many thanks

Ditch

Rescued attachment hub.jpg

JoelP - 1/11/05 at 05:42 PM

just a little query, should that picture say castor at the top? And if you are measuring castor from a casting line/slit etc, are you sure it is

vertical or in line with the tapers, as required?

ditchlewis - 1/11/05 at 08:49 PM

oops yes that should read castor.....

the split is part of the casting to allow for the removal and replacement of the donor sierra upright from the hub. on the sierra this was in the

vertical with the front strut, so i assume it is the best method of measuring verticallity. Is there another way?

ditch

JoelP - 1/11/05 at 09:03 PM

not thought about it myself, just thought id make sure you did! Remember that this part, though perpendicular to the strut, might not be in line with

the two ball joints. Good luck, but remember that you will always get best setup if you take it to a pro anyway, who can use expensive machinery and

experience to get everything spot on

givemethebighammer - 1/11/05 at 09:16 PM

quote:

Originally posted by JoelP

not thought about it myself, just thought id make sure you did! Remember that this part, though perpendicular to the strut, might not be in line with

the two ball joints. Good luck, but remember that you will always get best setup if you take it to a pro anyway, who can use expensive machinery and

experience to get everything spot on

I don't know Joel, I did a pretty good job with a camber gauge (ebay bargain), gunson's trakrite toe gauge and a bit of patience

I managed to set the front camber caster toe and the rear camber toe.

car handles very well so can't be far out.

This is not what I have but could be OK

http://cgi.ebay.co.uk/Camber-Gauge-Magnetic-Sealey_W0QQitemZ8009782523QQcategoryZ30917QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

[Edited on 1/11/05 by givemethebighammer]

JoelP - 1/11/05 at 09:22 PM

i know what you are saying mate but mine feels glued down too even though the toe doesnt even look right! I think it feels great just because its so

nimble, Jon Ison got his setup professionally (think it was him anyway) and was very happy with the results.

[Edited on 1/11/05 by JoelP]

ditchlewis - 2/11/05 at 10:29 AM

Many thanks

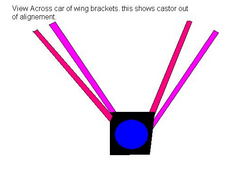

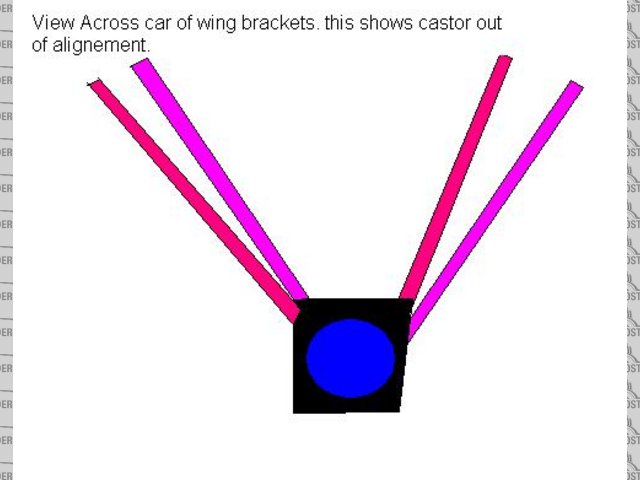

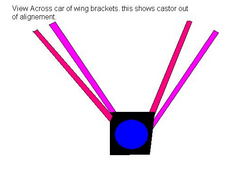

I just want to get the car in a safe predictable state. the problem that i have is that the brackets for the front wings are identical and handed,

they are located into the hub by the slot in the hub and the bottom ball joint. they position on the hubs indintically (same measurements from brake

bolts etc) but as viewed accross the car they are both at a different angles. I think that this would indicate that the castor is out? (see attached

pic)

I agree and i will get a pro to set it up after the SVA, but i want the brackets to line up so i can fit the wings.

regards

Ditch

Rescued attachment wing brac.jpg

blueshift - 2/11/05 at 08:59 PM

Or your wing brackets aren't identical / aren't identically mounted to the uprights. I wouldn't set up your castor by going off the

cycle wings.

grusks - 2/11/05 at 10:39 PM

I've all ways found this type of gauge spot on. hold it against the wheel and read away.

You can make your own with a bit of ali bent at 90`and pertractor and a bit of string etc.

Rescued attachment ADA.jpg

britishtrident - 3/11/05 at 11:50 AM

The important thing is to get the car at its working laden ride height (for a Locost this is normal one up ie driver only )--- one way of doing this

is to make 4 setup blocks to fit under the chassis is to screw the springs down untill the chassis just rest on the blocks.

I have always found the price of the equipment used is inverse proportion to the brain power of the guy using it.

The most valuable tool when setting a car up is a truly level floor to use as a datum.

The trackrite is probably one of the most accurate methodd of setting toe-in across the axle. Set the toe as close as posible for each wheel using

string methods then set the overall toe with a trackrite or if you ar lucky enough a Dunlop Optictal tracking beam.

Likewise camber --- which isn't super critical anyway as long as it is in the right ball park is best set with fairly simple tools that use

either a plumb line or spirit level.

Caster is the really tricky one it isn't easy measure directly and the important bit to get equal both sides.

givemethebighammer - 3/11/05 at 10:03 PM

the camber gauge I used is the same as the one grusks posted. It came with a set of instructions for measuring the caster, involved measuring the

camber of the wheel at different positions through the movement of the steering. A bit of simple maths (also explained with the gauge) and you have a

caster figure. The trakrite is a breeze to use. Only downside is that you have to take it apart and clean it fairly often as the grit from the tyres

gets in the rollers and affects it's operation.