David

Can anyone tell me what size and thread the locknuts are for mk2 escort metric rack???

and possibly where to get them from?.

cheers

Ray

D you mean the locknuts on the steering rack. They are the same as Sierra ones and are available from Ford dealers about 50p each.

They are M14. Available from any fastenings place for a few pence.

David

thanks for the info.

Ray

A handy wee tip I probably picked up off here, get some 12mm Stainless nuts & get them bored & threaded to 14mm, they look far neater on the

tie rods than a 14mm nut & are still plenty strong for this application.

HTH Cheers, Steve.

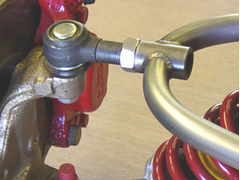

I did a similar thing on my top suspension b/j.

Bored an S/S M16 and taped it M18 fine.

Your right Steve, much neater.

see pic

Paul G

Rescued attachment lock-nut-m18-s.jpg

907, was that pic taken pre camber set-up? The TRE seems to stick out quite far.

quote:

Originally posted by Rorty

907, was that pic taken pre camber set-up? The TRE seems to stick out quite far.

If I understand your request correctly, I normally leave half the jam nut's width of thread between the nut itself and the end of the threaded

section of the stud. I see though, you have used a full nut and not a thin jam nut, so, for an 18mm thread, I would leave a tad over 4mm of thread

showing after the nut.

The whole idea behind a jam nut is to provide a locking device while allowing as much male thread as possible to remain inside the female thread.

However, if you meant how much I would recommend moving the threaded sleeve/camber adjuster rearwards in relation to your current one to attain more

caster, then I would have to say I'm not sure in terms of longitudinal mm.

I don't have a copy of The Book, so I can't quickly draw it up for you either. I would still aim for around 5.5-6 degrees for a car of that

type, weight and size.

If you send me your set-up data, I'll gladly draw it up for you.

quote:

Originally posted by Rorty

If I understand your request correctly, I normally leave half the jam nut's width of thread between the nut itself and the end of the threaded section of the stud. I see though, you have used a full nut and not a thin jam nut, so, for an 18mm thread, I would leave a tad over 4mm of thread showing after the nut.

The whole idea behind a jam nut is to provide a locking device while allowing as much male thread as possible to remain inside the female thread.

However, if you meant how much I would recommend moving the threaded sleeve/camber adjuster rearwards in relation to your current one to attain more caster, then I would have to say I'm not sure in terms of longitudinal mm.

I don't have a copy of The Book, so I can't quickly draw it up for you either. I would still aim for around 5.5-6 degrees for a car of that type, weight and size.

If you send me your set-up data, I'll gladly draw it up for you.

And again

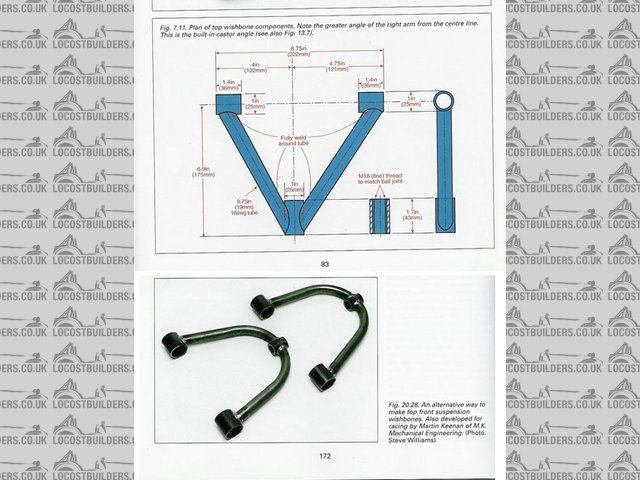

Bellow are pics from "the book"

I'm thinking that for caster I should deduct from "102" and increase "121" by an amount to give me the 5.5 - 6 deg;

and change 175 to give me the 4mm of thread that you suggest.

As you can see I have made the curved versions using the dims off the angled ones.

Cheers, Paul G

Rescued attachment wb-book-dims-2s.jpg

quote:

Originally posted by 907

quote:

Originally posted by Rorty

If I understand your request correctly, I normally leave half the jam nut's width of thread between the nut itself and the end of the threaded section of the stud. I see though, you have used a full nut and not a thin jam nut, so, for an 18mm thread, I would leave a tad over 4mm of thread showing after the nut.

The whole idea behind a jam nut is to provide a locking device while allowing as much male thread as possible to remain inside the female thread.

However, if you meant how much I would recommend moving the threaded sleeve/camber adjuster rearwards in relation to your current one to attain more caster, then I would have to say I'm not sure in terms of longitudinal mm.

I don't have a copy of The Book, so I can't quickly draw it up for you either. I would still aim for around 5.5-6 degrees for a car of that type, weight and size.

If you send me your set-up data, I'll gladly draw it up for you.

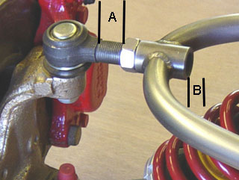

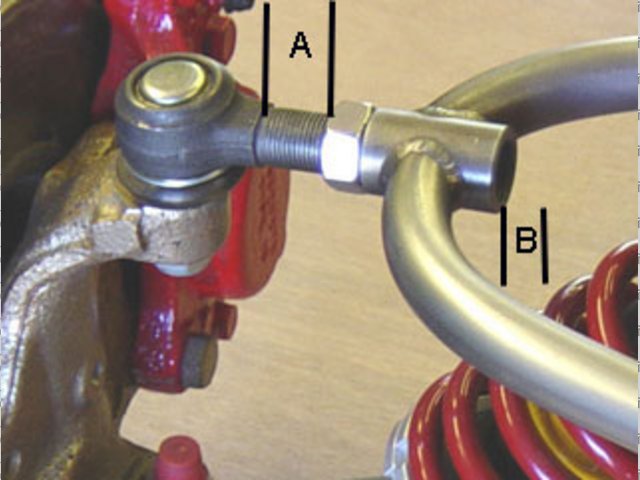

Hi again

Just to clarify, would you say I need to end up with (after setting caster) "a tad over 4mm of thread showing" at A or B. see pic. (another pic to follow)

quote:

Originally posted by 907

And again

Bellow are pics from "the book"

I'm thinking that for caster I should deduct from "102" and increase "121" by an amount to give me the 5.5 - 6 deg;

and change 175 to give me the 4mm of thread that you suggest.

As you can see I have made the curved versions using the dims off the angled ones.

Cheers, Paul G

Thanks Rorty for your advise, I'll bear it in mind when I remake the w/bones.

The Lotus 907 is a lightweight, all ally, wet liner engine, and is mounted well back

in the chassis, behind the front axle line, so I'll go for more rather than less caster.

(does that make my car a middy?)

Thanks again, Paul G