Rescued attachment Lotus 003.jpg

Anyone anby experience with soldered nipples on the ends of cables such as the handbrake, accelerator and clutch?

Pat...

If you're wondering about their strength, I'm sure I read once that someone had tested their soldered nipple and had managed to snap the

cable before the nipple gave way, so they're easily strong enough!

Pete

Make sure you 'fan out' the individual strands so as they ffill the recess in the nipple, dress back with a file once soldered, and all the

usual cleanliness comments.

Definitly less prone to failure if made correctly than the screw type.

Mick

yep, used em a few times, no probs, but as Mix said, make treble sure that everything is spotlessly clean first. (wash in acetone or similar)

If you need to cut the inner cable don't use pliers sidecutters etc . A tip I was shown years ago is to use a sharp chisel, place the cable onto a hard surface such as a vice , place chisel across point to be cut and give the chisel a smart tap with a hammer , clean cuts everytime with no fraying. HTH .

quote:

Originally posted by scoobyis2cool

If you're wondering about their strength, I'm sure I read once that someone had tested their soldered nipple and had managed to snap the cable before the nipple gave way, so they're easily strong enough!

Pete

That might have been it, it was a long time ago so I can't remember for sure. Either way I think it shows there aren't any strength

issues!

Pete

Any pics of the bolt croppers?

I pressume you can also do it with a smaller bolt and it still be strong enough?

Cheers,

Pat...

Some solder will inevitably wick its way along the cable for a short distance and this is where the cable will break..right where the solder ends.

The cable's strength will have been lost due to being over heated and it is at its weakest right where the solder ends.

It's not a difficult thing to do, but if your cables keep breaking just short of the nipples, you know you're burning the cable. If the

cable gets more than dull red, you've destroyed it. Use a low flame and heat it gently then when the nipple and cable are the same shade of dull

red, then touch the solder onto the end of the cable until it almost fills the reservoir in the nipple. If it's done cleanly and slowly,

there's no need to splay out the ends of the cable.

Finally, don't disturb the cable/nipple until it's stone cold and then rinse it under the hot tap to remove the hardened (and corrosive)

flux.

quote:

Originally posted by Avoneer

Any pics of the bolt croppers?

I pressume you can also do it with a smaller bolt and it still be strong enough?

Cheers,

Pat...

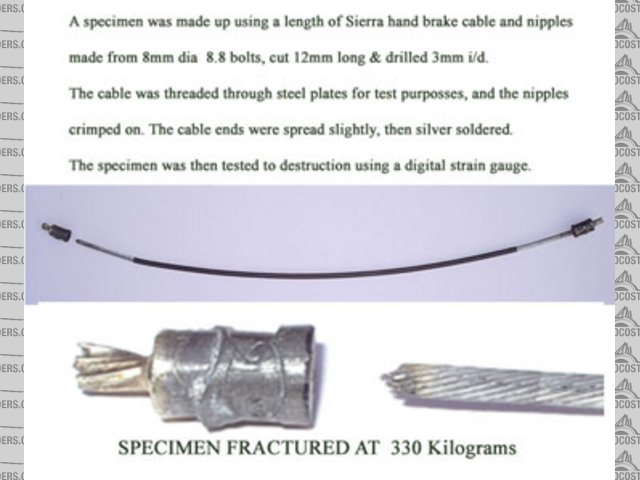

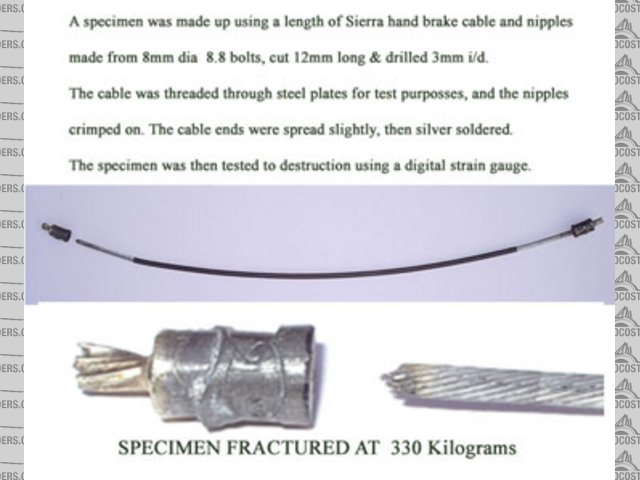

Hi. Was this it ?

I should point out it is silver solder, not soft solder.

HTH Paul G

Look in a B&Q Wharehouse in the plumbing section --- I think Halfords might also do among the welding accessories.

Re cutting cables before threading through the nipple solder the cable leaving a bit extra first then cut at the soldered section. Then thread

through the nipple and cut the soldered bit off and fan out the ends and solder to the nipple.

Try searching for info under 'hard soldering'

I use 'Easyflow' grade and flux

Mick

Thankyou both.

I may be doing this soon as well. When you guys discuss the solder, are you talking about a standard electronics wiring solder gun and wiring solder?

Or are you talking about a butane torch with non electrical solder?

--Thanks, Chris

I'm surprised that easyflo silver solder is recommended - I've often used this in model engineering, and it usually requires the piece to be

taken to a dull orange before it will start to flow (and easyflo is one of the lowest-temperature silver solders). I would have thought that this

temp would have wrecked the properties of the cable.

I would have thought that a very hard tin-lead solder such as Comsol* would be more appropriate (* if you can still get it!).

David

When I shortened the handbrake cable on my car i threaded it through the nipple spread the ends and welded it with the mig. I was unsure about

silversoldering it due to the heat on ther cable but have had no problems this way, I think soft solder would pull through after a while.

paul.

MIG works surprisingly well on handbrake cable :-)

You can introduce a bit of solder - not too warm - to the area you want to cut, then you can use ordinary wire cutters and it will cut cleanly without

fraying.

For the nippling(!) I used the RH method, which I thought a bit suspect at the time, of drilling hole lengthways through a piece of bolt, threading

the cable through a then giving it a welt with a big hammer. Its still holding firm 10 years later.

For silver soldering I use a little oxy-propane torch and pre-flux rods

An old motorcycling trick my old-man showed me once was to tap a small Cobblers Tack into the end of the cable to spay it out, then solder it in. Acts a bit like the wedge in the top a a hammer stale.