Cu-Ni-fe (ie "Cuniffer"

is the best option.

is the best option.

As the title says

is there any problem with mixing copper and copper/nickel brake pipes ?

Fitted the pipe kit from Tiger (copper) but then decided to change the design slightly and bought some new pipe for the job but got copper/nickel pipe

by mistake.

would it be OK to mix'n' match these pipes or do i need to replace all the copper ones ?

Cheers

Dave,

I can't imagine that there would be any problem with mixing the two. The cu-nickel pipe will look slightly different (sort-of grayer colour) and

will be a better material) but otherwise there's no difference.

cheers,

David

Should mix ok but personally I would never feel confident driving a car with copper brake pipes.

Cu-Ni-fe (ie "Cuniffer" is the best option.

is the best option.

Agree with BT...should be Ok, but would go for Kunifer (I think it's spelt) all round if possible, it's much better...

/ixing both should be fi9ne, we used to mix when retubing ac condensors with no noticeable differential corrosion in service.

Mac

But agree that CUNI is far superior, if i remember correctley CuNi brake tube in the uk is CuNi 90/10 (percentages) 70/30 is better but probably

overkill and will also be a bit harder to work with.

I think the main thing you'll find is if your using a Clarke cheapo flare tool it dont like kunifer too much.Mind you that could just be the one

I'm using, while copper flared out perfectly.

Personally I would be more concerned with how it flared as to whether which is stronger but the flare is the first bit that will pop

Kunifer is easier to make a neater job of because its harder.

They are both to BSI so I cant see a problem.

Cheers,

Bob

[Edited on 20/6/05 by splitrivet]

The problem with using copper tubing on a car, is that the vibrations and inevitable movement will work-harden the copper leading to fractures and

thus leaks.

That's why nickel and iron were alloyed with copper to make Kunifer which is specifically designed for automotive use.

It's not expensive to buy and has major safety implications.

quote:

Originally posted by splitrivet

I think the main thing you'll find is if your using a Clarke cheapo flare tool it dont like kunifer too much.Mind you that could just be the one I'm using, while copper flared out perfectly.

Personally I would be more concerned with how it flared as to whether which is stronger but the flare is the first bit that will pop

Kunifer is easier to make a neater job of because its harder.

They are both to BSI so I cant see a problem.

Cheers,

Bob

[Edited on 20/6/05 by splitrivet]

have said this to a few people but it is not nice to hear.......you need a proper flaring tool, a lever action one like the Sykes Pickavant or Automec tools. I got one of these and it flares kunifer well and manages steel bundy pipe ok as well!

I cant honestly see the problem with copper,back in my fridge engineer days we used flared 1/4 copper and never had a problem with work hardening and

that had a thinner wall and some of the old condensing units used to vibrate like a bog house door in a force 10.

You takes yer pick Dave dodgy flare or remote chance of work hardening, I know what i'd go for.

Cheers,

Bob

[Edited on 21/6/05 by splitrivet]

quote:

Originally posted by splitrivet

...we used flared 1/4 copper and never had a problem with work hardening and that had a thinner wall and some of the old condensing units used to vibrate like a bog house door in a force 10.

You takes yer pick Dave dodgy flare or remote chance of work hardening, I know what i'd go for.

quote:

Originally posted by Rorty

I think you'll find that copper lines are now illegal for brake systems...

quote:

Originally posted by flak monkey

quote:

Originally posted by Rorty

I think you'll find that copper lines are now illegal for brake systems...

Are they really? Why are so many kits getting through with copper pipes then?! Most of the kit manufacturers supply copper lines as well.

quote:

Originally posted by flak monkey

quote:

Originally posted by Rorty

I think you'll find that copper lines are now illegal for brake systems...

Are they really? Why are so many kits getting through with copper pipes then?! Most of the kit manufacturers supply copper lines as well.

Automec are one of the largest suppliers of brake pipe 'kits' in the market and they supply copper pipes as standard. These kits are

supplied in comprehensive kits by many manufacturers including Tiger.

their site has info about BS conformity

Here

My issue with my cheapo flaring tool isn't that it won't flare the pipe, just that the resulatnt flares are distorted and in some cases

stepped. will post some pics of the results tomorrow.

I'm not being pedantic, but Automec's page about copper and Cu/Ni tube seems a bit ambiguous. The

page is headed "Brake and fuel pipe coils" and it goes on to say "Top quality

thick-walled (0.9mm 20swg) Copper and Copper Nickel coils, conforming to BS2871 Part 3, C106/CN102."

I would take that to mean they stock brake tubing and fuel tubing and that "Copper Nickel coils, conforming to BS2871 Part 3, C106/CN102."

refers only to the Cu/Ni tubing. It doesn't specifically state copper complies to the same standard. (Or am I nit-picking/not reading it

correctly?)

I would like to see an unequivocal statement that pure copper tubing complies.

It's all moot IMHO anyway, because Kunifer is a far superior product and I simply wouldn't trust my life to another product with reliability

questions hanging over it.

For the same reasons, you wouldn't build a chassis from Al; it would work for a while, but you wouldn't receive any warnings before it could

catastrophically fail.

quote:

Originally posted by Rorty

quote:

Originally posted by splitrivet

...we used flared 1/4 copper and never had a problem with work hardening and that had a thinner wall and some of the old condensing units used to vibrate like a bog house door in a force 10.

You takes yer pick Dave dodgy flare or remote chance of work hardening, I know what i'd go for.

Kunifer and similar manufacturers must be kicking themselves with that bit of information; all that time and research they've wasted!

I think you'll find that copper lines are now illegal for brake systems and they must have based their decision on something other than the colour of the stuff.

quote:

Originally posted by splitrivet

...thats why they still sell it stamp it down the side with a BS, DIN and ISO approval number

quote:

Originally posted by splitrivet

quote:

Originally posted by Rorty

quote:

Originally posted by splitrivet

...we used flared 1/4 copper and never had a problem with work hardening and that had a thinner wall and some of the old condensing units used to vibrate like a bog house door in a force 10.

You takes yer pick Dave dodgy flare or remote chance of work hardening, I know what i'd go for.

Kunifer and similar manufacturers must be kicking themselves with that bit of information; all that time and research they've wasted!

I think you'll find that copper lines are now illegal for brake systems and they must have based their decision on something other than the colour of the stuff.

So perhaps thats why they still sell it stamp it down the side with a BS, DIN and ISO approval number,fit it to motors and pass an MOT with it all because of a cunning plot to wipe out europes pedestrians with brakeless motors.

Of course Automec dont have a web forum to glean information from one of the worlds top metallurgists.

What a pipe.

Cheers,

Bob

DIN, ISO and BS numbers are like spanners they have to be the correct one for job, copper pipe is definitely not to SAE standards for brake lines,

and for automotive purposes SAE are the ones that matter. In fact the use of copper for car brakes is specifically illegal in some states of the

US.

For more info see this article

http://www.dimebank.com/BrakePlumbing.html

While I do not agree with everything in the article I would like to underline the problems of copper. Having had fair bit of experience working on

cars built in the 1920s I have seen copper fuel lines fail. The pipe becomes hard and brittle and usually after a slight disturbance tens to split

parrallel to its' axis, the failure appears not unlike "season cracking" in brass.

[Edited on 22/6/05 by britishtrident]

quote:

Originally posted by DaveFJ

Automec are one of the largest suppliers of brake pipe 'kits' in the market and they supply copper pipes as standard. These kits are supplied in comprehensive kits by many manufacturers including Tiger.

their site has info about BS conformity

Here

My issue with my cheapo flaring tool isn't that it won't flare the pipe, just that the resulatnt flares are distorted and in some cases stepped. will post some pics of the results tomorrow.

most of the parts dealers over here sell copper brake pipes.

a quick look at the VWP catalog:

VWP

OR CBS:

CBS

To be honest this argument is getting a little silly now - obviously it is legal or it would never pass SVA. There may well be a fatigue problem on a

car that is going to do 100000 mile plus but not on an avarage kit that will only ever do a fraction of that.

Although this is all very interesting i still can't get a decent flare on Kunifer and as a coil of copper (which i can get a good flare on) is a

damn sight less than a 'decent' flaring tool I am now thinking of throwing this Kunifer crap in the bin and getting a coil of copper.

[Edited on 22/6/05 by DaveFJ]

Dave,

I bought a really effective tool from Motormania in Ipswich a year or so ago - its use is described

here.

It made very neat flares on kunifer without difficulty.

Oh - it's cheap, as well!

If you're still stuck, send me a U2U and I'll give you a demo.

David

[Edited on 22/6/05 by David Jenkins]

defnitely nowt wrong with those old moprod flaring tools mentioned on that link.

I did have the snap-on/blue point one though and it does wreck the pipe, I wouldn't bother with it on copper or kunifer, as I said, it leaves

gouges in the pipe right near the flare which are sure sources for cracks.

I use a 20 year old Sykes-Pickavant it produces pefect flares every time for me and I have never broken a press tool -- just as well because the

design has changed and I am not sure if spares are still available.

The key to good flaring tool is that it holds the tup part of press tool aligned with the die.

If flares go off centre it is usually because too much pipe is protruding from the die.

quote:

Although this is all very interesting i still can't get a decent flare on Kunifer and as a coil of copper (which i can get a good flare on) is a damn sight less than a 'decent' flaring tool I am now thinking of throwing this Kunifer crap in the bin and getting a coil of copper.

[Edited on 22/6/05 by DaveFJ]

Im not gonna get into who's right/wrong, im not qualified for that but...

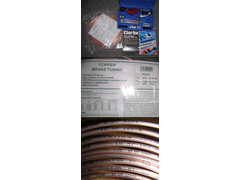

I used the kit in the pic below to do my escort's brakes for its MOT. I asked an independant garage (not supplying pipe or doing any of the work)

about Kuniffer and they recomended I stick with copper.

MOT station checked my work closely and OK'ed it without issue.

Included are pics of pipe used & it's info sheet, Is this plain copper or an alloy of some kind?

I would be interested to know as I will do differently in the future given sufficent reason to.

PS. I got even (not off center) flares with this tool but there were griper jaw marks on the copper pipe from the tool.

-Steve-

Rescued attachment CombinedImageWeb.jpg

Same tube as I used Steve same flare kit,both for the locost and my daughters car for a brake reline when it failed MOT.

No probs at all,the clamp marks from the flare block didnt cause any hitches.

Problem I had using kunifer with the flare kit was it just pushed the tube through the block as I was flaring it, even though I tightened the wing

nuts with an adjuster.

The snap on flare block that I had some years ago was the same principal but was far superior..Lent it out to some Tw*t who never returned it.

Cheers,

Bob

I used the Clark flaring tool and Kunifer and had no problems apart from stripping one of the wing nuts. I got a brass one from the local bolt shop and it's been alright since.

If my memory serves me right Pete my brother in law who used to be the manager at the local machine fart told me they had changed the manufacturer of

the kit some years ago,and they'd had a load of returned items shortly afterwards.

Could be you have the decent one.

Cheers,

Bob

[Edited on 23/6/05 by splitrivet]

Look at copper pipe this way --- a Coil of 15mm copper water pipe freshly bought from Plumb Centre or B&Q is nice and easy to work with, but plumb your new bathroom with it go back a year or two later and try alter in the pipes slightly -- you will find in this short time the pipe has age hardened and is a almost impossible to give even a slight bend without kinking or splitting.

BS2871 = bog (!) standard general purpose copper pipe.

It is not just some states of the USA copper brake lines are illegal but Germany and" parts of Scandinavia" see this.

http://www.tr6web.com/Documents/tr6/brakelines.html

[Edited on 23/6/05 by britishtrident]

This is getting a bit boring now.

Plumbers copper in no way equal to the copper pipe used for brake lines or refrigeration its hard drawn copper usually for one thing and very low

grade,the flaming joints are usually soft soldered and is not made to cope with the pressures that a brake line would be expected to handle.

Read the label on the pic posted previously 3/16 will cope with 3100 lbs in sq, 1/2 1100 lbs in sq. this may give you a clue.

I dont doubt you it may be banned in scandinavia but we dont have winters 4 months long at temps that would freeze the rocks off a polar bear and

therefor have to throw more salt at the road than you do on your chips per square inch.

And as for your article the stupid tw*ts got more chance of being beheaded by his triumph heralds forward hinged bonnet than he has his copper brake

lines giving way,so I wouldnt be taking any advise off of that sad sod.

Cheers,

Bob

[Edited on 23/6/05 by splitrivet]

[Edited on 24/6/05 by splitrivet]

All copper pipe is soft when you buy it it both work hardens and AGE hardens.

yup, and silly or not, those little grooves left by crappy flaring tools are brilliant stress raisers, and look utterly shite.

I have had the daftest of items fall off my grasser due to fatigue due to it's solid mounted engine, copper lines would last all of 5 mins. The

rivets pop their heads off on a regular basis.

I may be nitpicking but that's why I binned my crappy old flaring tool!! Buy a proper one!!!!!!!! (you could even offset the cost by making lines

for those without the tool at a VERY competitive rate (preferably beer!!))