Does a live axle really need a panhard rod?

Reason I ask is that I think the panhardrod will interfere with the handbrake bar/cable arrangement once fitted.

Anyone got round this?

Cheers,

Pat...

not necessarily a panhard rod, but it does need something to prevent lateral movement. have you considered the alternatives? ie watts linkage etc

If there are trailing arms fitted will these do the same job?

I am looking at de dion myself but thought the principle of the panhard the same on both.

I really don't want to fit a panhard either if I can help it. Does anyone have a diagram of a watts linkage?

Would prefer a panhard rod.

Hi Chunkie - how's it going?

Panhard rod is easy with Sierra back end!

As I'm using Mk2 Escort rear end, it will be awkward.

Pat...

Panhard rod does some serious hard work so it definitely is needed. My mate made his first one from undersize tube and it lasted under a week. It bent like a banana. I have a capri axle which is like MK2 but longer, why is it a problem with the Escort?

Because the handbrake cable and bar go right acroos the back of the axle.

There's enough room for the trailing arm brackets, but the panhard rod may foul on the horizontal cable.

Pat...

I redrilled my brake backplates so that the slave cylinders where at the top, and made my own compensatorswivel thingy and welded it to the top of the

axle near the diff and then used a Marina 2 into 1 cable.

Didn't have probs with clearance to Panhard rod.

Get a late model Ital hand brake cable it does away with the solid rod and the stupid rubber hinge thingy which causes immense problems when it goes

hard with age. The Ital part is a straight replacement for the Escort cable except it has a much nicer threaded adjuster an runs a wire cables across

the axle to each wheel instead of the 5/16" rod to one wheel. All it needs is a large cable tie to support (as on the Ital) and allows the

rubbe hinge to be ditched --- this was quite a common mod on Escorts in the 80s as it got round the problem of the rubber hinge going hard with

age.

The late Marina 1700 /early Ital cable will also work but has a thin metal rod running to one wheel so the late Ital is the best.

NB early Marina cable will not work for this mod as it is almost identical to the Escort type.

had the same prob -- made a bracket at the axle end which acted as a spacer. The origional handbrake mechanism then fitted ok.

There's a pic on my phot's showing the bracket----a bit of cutting and shutting

hope this helps -phil

quote:

Originally posted by Surrey Dave

I redrilled my brake backplates so that the slave cylinders where at the top, and made my own compensatorswivel thingy and welded it to the top of the axle near the diff and then used a Marina 2 into 1 cable.

Didn't have probs with clearance to Panhard rod.

Thanks guys.

Will wait to see how it's going to work when it's all in situ.

What about Ron's idea of using two handbrake cables, one to each back plate - Allegro wasn't it?

Phil M - Like your idea best - does the cable go through the spacer? Also, who's rear arches are you using as they suit the car really well -

look good by the way.

Pat...

Hi avoneer.

SO basically, on a Dedion or live axle you need trailing arms AND a Panhard rod?

I'm glad I'm on a sierra rear end as the whole handbrake thing seems a bit of a nightmare!!!

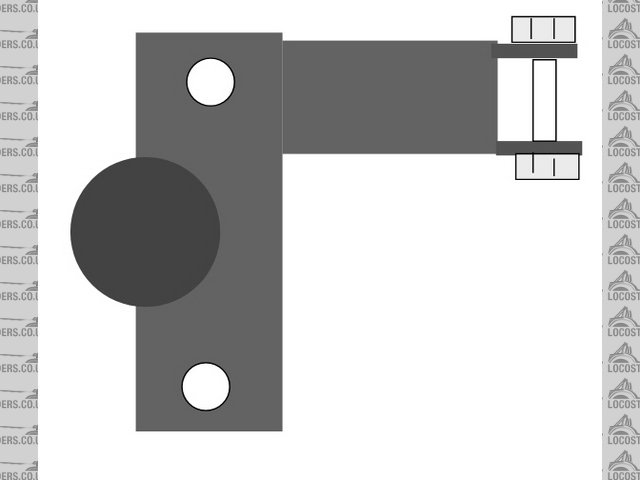

I also used a capri axle, with the standard handbrake cable, I lifted the chassis end of the panhard rod and everything clears nicely

Rescued attachment CapriHandbrake.jpg

...like this

Rescued attachment Inner Rear Panel.jpg

quote:

Originally posted by chunkielad

Hi avoneer.

SO basically, on a Dedion or live axle you need trailing arms AND a Panhard rod?

I'm glad I'm on a sierra rear end as the whole handbrake thing seems a bit of a nightmare!!!

Hi,

No, I'm not using any Sierra drive train.

All mk2 Escort live axle with trailing arms and a panhard rod - just wondering how people have fitted the panhard rod due it possibly contacting the

handbrake cable at one side when the axle move up and down.

Pat...

I'm using sierra ends on a De Dion (from gts probably) tube. I just don't get why you need both trailing arms and panhard rod. Surely they

do the same thing in a different way, or am I being stupid?

Sorry to semi Hijack the thread.

Trailing arms control up and down location, panhard rod controls sideways. Leave it off and watch as the wheels chew away at your chassis every time you corner. On a de dion it will be even worse as the drive shafts will disconnect from the diff due to no sideways location.

Ahhh, what you just said make everything make sense!!!

Sidewards movement!! I thought, from the way it had been explained to me that it was another way to stop the wheels moving front and back. I

couldn't understand how the panhard did that but now you said that, It makes sense how it works!!!!

Doh!!!

quote:

Originally posted by Avoneer

Thanks guys.

Will wait to see how it's going to work when it's all in situ.

What about Ron's idea of using two handbrake cables, one to each back plate - Allegro wasn't it?

Phil M - Like your idea best - does the cable go through the spacer? Also, who's rear arches are you using as they suit the car really well - look good by the way.

Pat...

The book Locost axle is strictly speaking over located --- to locate an axle only 4 links are required BUT at least one must be angled to give

transverse location.

This is what is used on the Cortina 3+ (angled uper links) and in a different form the original Lotus/Cateham 7 S1 to S3 (S4 was different) on

which which combined 2 lower links to form an "A" frame.

However 4 link location tends to cause problems --- Lotus/Caterhams crack axles and Cortina chew through upper bushes.

Going back the Locost book suspension it is over located -- strictly speaking you can only get away with this geometry if transverse location is by a

centrally mounted Watts linkage but the real world Locost gets away with the geometry error because of the limmited suspension movement and some

compliance in the suspension bushes and the chassis mounting and axle flex very slightly. --- This is one of the reasons on my car I use rubber

bushes using non compliant bushes such as rose joints on all 10 mountings is likely to cause problems with fatigue cracking later in the car

life.

[Edited on 14/1/05 by britishtrident]

So am I right in saying a Watts linkage is like two panhard rods but just going to the centre instead of all accross?

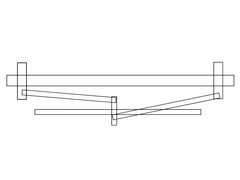

My idea of a Watts linkage is like this.The ends would be rose jointed of course so they can be fine tuned.

Rescued attachment watts.jpg

of course all dimesion would be symetricall - otherwise that axle would be travelling sideways aswell

I once did some work on a much modified Plus 4 Morgan that belonged to a well known female scottish Chain Gang member it (the car) had a spigot

welded to the back of the diff casing --- the spigot carried a very large ball bearing the outer race of which ran between vertical angle iron tracks

welded to the chassis thus providing lateral location. --- made me smile ;-)

----I0I----

[Edited on 14/1/05 by britishtrident]

[Edited on 14/1/05 by britishtrident]

I'm going to have to think about the watts link now - do the ends of the longrods need to be separated in height by the length of the middle

one... duh brain hurts... I'll get back on that one.

BT - I'm sure you could use rose joints - it's just that the axle vertical movement would describe a transverse arc (radius = panhard rod

length), rose joints would allow this, no stretching or chassis bending called for as long as all the trailing arms are equal length.

Hi,

Just read the bit about fatigue cracking resulting from having rod-ends throughout the rear suspension.

As I have exactly such a setup, can you please elaborate as I can't see why you think this will happen. My suspension moves very nice and freely

(by hand) in all permitted directions and angles. I also have adjustable lengths on all 5 links to ensure that there are no static loads anywhere. I

just can't see where the fatigue cracks would come from.

I know my suspension will transmit road noice like crazy but I was under the impression that it would perform fine and didn't envisage any safety

issues.

Cheers,

Craig.

quote:

Originally posted by Bob C

I'm going to have to think about the watts link now - do the ends of the longrods need to be separated in height by the length of the middle one... duh brain hurts... I'll get back on that one.

BT - I'm sure you could use rose joints - it's just that the axle vertical movement would describe a transverse arc (radius = panhard rod length), rose joints would allow this, no stretching or chassis bending called for as long as all the trailing arms are equal length.

Yo BT - I need to think about that, clearly one of the trailing links is ostensibly "redundant" but I had this comfortable notion that as

long as they were all the same length it was OK. I can see I'll have to check this out on solidworks...... (3D geometry is just too hard)

BTW liked the morgan story - sort of fits well in a motor with "sliding pillar" IFS. Must have made a terrible racket on the road....

Bob C

quote:

With 5 solid joints Roll + bump causes torsion on the axle

quote:

Originally posted by Bob C

Yo BT - I need to think about that, clearly one of the trailing links is ostensibly "redundant" but I had this comfortable notion that as long as they were all the same length it was OK. I can see I'll have to check this out on solidworks...... (3D geometry is just too hard)

BTW liked the morgan story - sort of fits well in a motor with "sliding pillar" IFS. Must have made a terrible racket on the road....

Bob C

Gazza - you and me are wrong & BT's right - I just ran a quick solidworks model and as BT says, bump + roll twists the axle.

We live and learn!

Cheers

Bob

I just checked out the watts link & yes you do have to vertically separate the pivots at the ends of the long transverse links by a distance equal

to the length of the middle link.

So now you know.

Cheers

Bob C

That's enough solid modelling for me. Time for a beer..

could have told you that - ive had one beer too many tonight

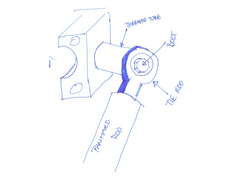

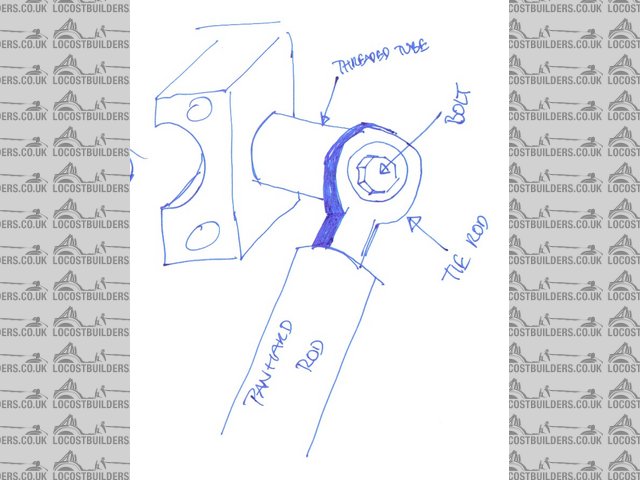

Back to my problem for a minute....

Would it be ok to weld a 2" solid bar sticking horizontally straight out of the back of the trailing arm bracket, tap a hole down the middle of

it and then connect the panhard rod to this bracket using a tie rod with the bolt passing through the tie rod and bolting into the end of this

2"bar?

Hope that makes sense,

Pat...

Britishtrident,

Whilst I agree with most of your statement regarding axle location, I feel rose joints are the way to go. They have MORE lateral movement than bushes

as they are spherical bearings. The poly bushes are the worst, being almost rigid in the horizontal plane, causing the chassis to twist and eventually

suspension bracket failure.

Marcus

quote:

Originally posted by Marcus

Britishtrident,

Whilst I agree with most of your statement regarding axle location, I feel rose joints are the way to go. They have MORE lateral movement than bushes as they are spherical bearings. The poly bushes are the worst, being almost rigid in the horizontal plane, causing the chassis to twist and eventually suspension bracket failure.

Marcus

Boo hoo hoo....

No one's answering my questions.

It is my post...

I'm popping my ball and going home...

You're all a bunch of good for nothing hijackers.

[Edited on 15/1/05 by Avoneer]

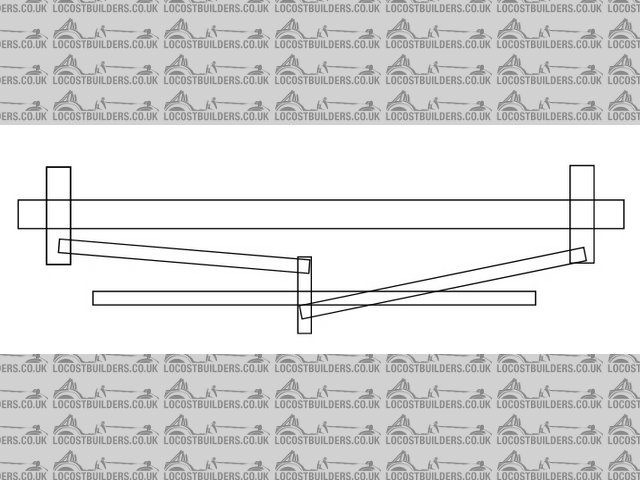

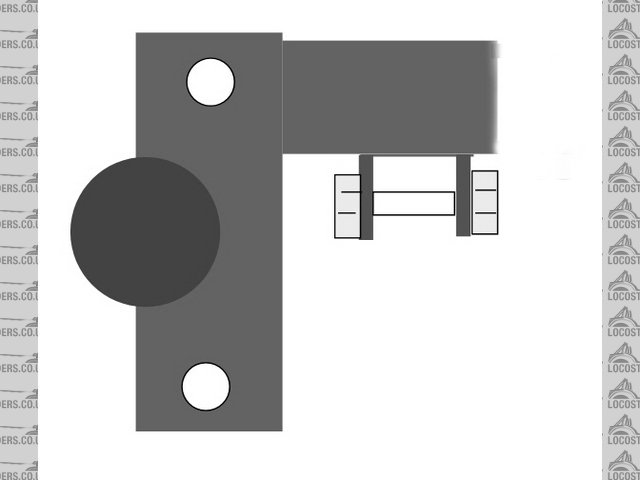

Why not extend the bracket out from the axle and bolt your panhard straight to it Pat? I didn't understand the tierod idea, can you draw it

out?

Rescued attachment hanger.jpg

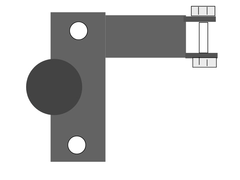

Hi Pete,

Excuse my crap drawings, but the idea is there - almost like yours, but with a rod end:

Rescued attachment 1.jpg

Mine uses a rod end but the other way on in double shear. You meant rod end not tie rod. You could use a square tube with a nut welded on a plate in

the end or weld a bracket to the underneath or the face.

Rescued attachment hanger.jpg

Just wanted to make it easy as I have a bit of threaded bar and it seemed to be the easiest solution????

this was strong enough to hold togethor and bend a half shaft when the car hit a "solid" object ????

Rescued attachment rearpanard.jpg

Cheers john - wish I had known about your pic before trying to draw the bloody thing!

And if it won't fit in with the handbrake bar and cable, I'll just use a separate cable to each back plate.

Cheers,

Pat...

jons looks fine to me, plus he says it works well! If you were bothered, you could sleeve the threaded tube in a square bit, and triangulate it to the

axle - guaranteed not to fail then! (or at least, not to fail first!)