Diff/Prop Hitting Chassis - Panhard Rod Required

Murdoc - 24/8/16 at 05:00 PM

Just bought a locost from someone on here and when cornering hard(ish) there is an awful scraping/grinding/knocking noise, my two guesses were

something on the bottom scraping or the diff/prop hitting the chassis. I remade an exhaust bracket that was too low and trimmed some excessively long

machine screws sticking out as they were clearly scraping (bent over). I'm left with the diff and prop hitting the chassis and side panels in the

tunnel. I'm going to put a Panhard rod in as there is excessive lateral movement. I have had a look at the book and there is a Panhard rod in

there, do people see them as an optional part?

I'm looking for pictures of how they are attached to the axles, has anyone got some to share? The pictures in the book don't include the

handbrake and hydraulic lines and it's quite tight. Is there enough room to weld the receiving bracket between the cable and lines? I need to

re-make the handbrake cable bracket anyway as it is too near the chassis.

I have some 19mm 1.6mm mild tube, I was planning to use rose joints so I can adjust the length. Is the 19mmx1.6mm up to the job? I'm trying to

avoid going excessive on the materials and adding too much weight, I can't imagine the loads are that high.

Thanks!

britishtrident - 24/8/16 at 05:07 PM

As it is you have just 4 parrallel links ? with no lateral location ?

Slimy38 - 24/8/16 at 05:09 PM

Judging by the picture you have 4 out of a 5 link suspension setup. The panhard rod is the fifth link, it's not something I would consider

optional.

Murdoc - 24/8/16 at 05:10 PM

Yes, I was a little surprised when I first had a look. That's why I asked if they are considered optional.

chris_smith - 24/8/16 at 05:10 PM

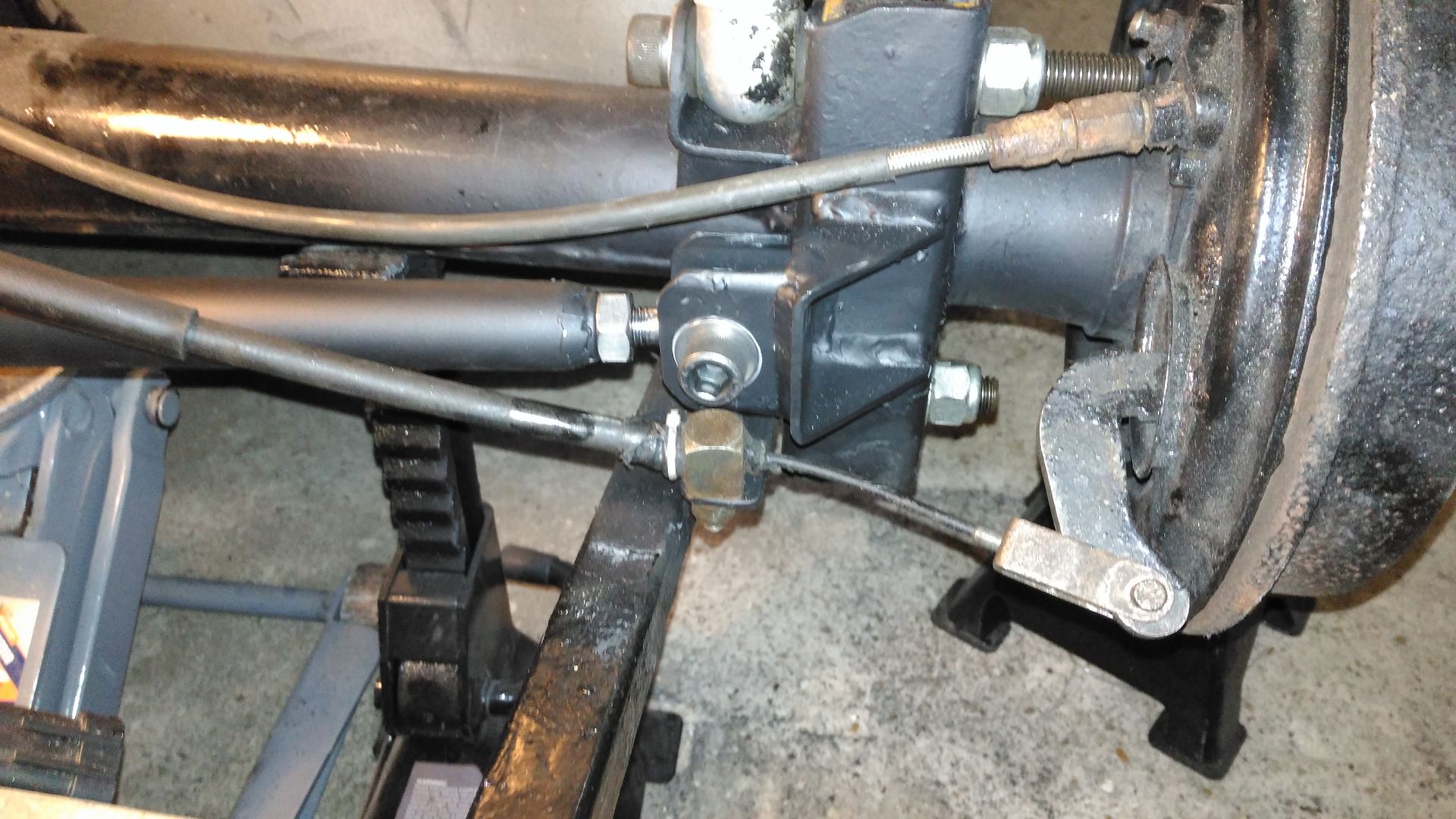

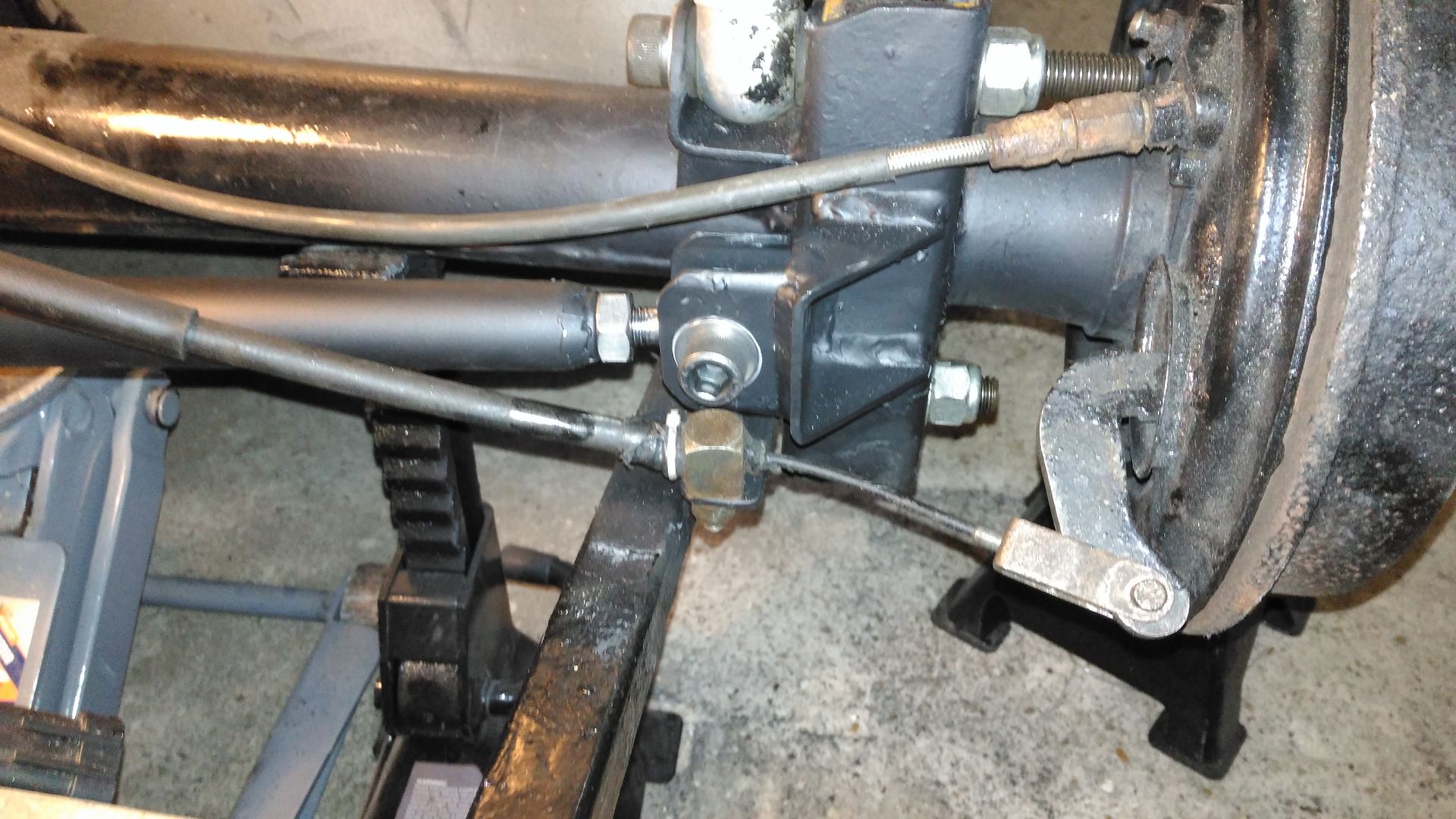

these are the only pics i could find from my previous build -

.jpg)

.jpg)

drum painted

Description

Murdoc - 24/8/16 at 07:24 PM

Thanks.

I have just ordered a pair of M12 rose joints and matching threaded inserts from McGill motorsports, they fit 25mm tube so that answers my earlier

question. about 19mm tube.

Is it possible the original builder omitted the Panhard rod in an ill advised attempt to save weight?

Nickp - 24/8/16 at 08:03 PM

quote:

Originally posted by Murdoc

Is it possible the original builder omitted the Panhard rod in an ill advised attempt to save weight?

Or an attempt to make a comedy handling clown car?

mcerd1 - 24/8/16 at 09:56 PM

A watts linkage could be an alternative to the panhard rod if you think that would fit any better / more easily

[Edited on 24/8/2016 by mcerd1]

Sam_68 - 25/8/16 at 08:03 AM

Are we to understand that this thing managed to get through IVA withoout any form of lateral location of the axle?

Murdoc - 25/8/16 at 08:19 AM

Looks like it, it's a bit strange as the rest of the chassis is really well built. All the welding is top notch and the finish is great. I'm

thinking it was either part built and sold or intentional for some reason and plans changed. Since 2009 no one else has noticed this or decided to

investigate the bad noise.

mcerd1 - 25/8/16 at 08:27 AM

I assume that this is the car ?

http://www.locostbuilders.co.uk/viewthread.php?tid=203956

Murdoc - 25/8/16 at 08:35 AM

That's it. Plenty work still to be done on it, but I wanted a project.

mcerd1 - 25/8/16 at 09:55 AM

looks like the previous owner did a bit of work too...

http://s131.photobucket.com/user/boylers11/library/locoblade?sort=3&page=1

Jeano - 25/8/16 at 12:29 PM

I can help a bit more on this

assuming this is your car

Then this is the refurb the previous owner did 2013 to 2016

http://www.corsasport.co.uk/board/viewthread.php?tid=661311&page=1

Andy D - 25/8/16 at 12:58 PM

quote:

Originally posted by mcerd1

looks like the previous owner did a bit of work too...

http://s131.photobucket.com/user/boylers11/library/locoblade?sort=3&page=1

In that pic is there a nut on the end of the axle panhard rod mounting? Has it been removed for painting, and someone forgot to put it back? .. I

can't imagine how bad it must handle without it fitted.

Murdoc - 25/8/16 at 01:23 PM

That looks like it was for an older set of longer shocks, the same mounting point is at the other end of the axle too. Also, there is no mounting

point on the chassis for the panhard rod. I may be able to use the old shock mounting point. I had a good look but I'm pretty sure one has never

been fitted.

The handling, surprising, isn't that bad but I haven't push it at all due to the noise!

[Edited on 25/8/16 by Murdoc]

prawnabie - 25/8/16 at 01:51 PM

Id be taking the paint off the trailing arms + chassis/axle brackets and checking for signs of fatigue, I would say that IF the axle has been moving

side to side, it may well have been flexing the brackets/chassis in that area.

Andy D - 25/8/16 at 01:51 PM

That mounting point is suspiciously in the exact same position as my Westy live axle. Very odd..

Top pic on this page:

http://forum.wscc.co.uk/forum/index.php/topic/104326-identifying-different-types-of-rear-suspension-and-diffs/

Sam_68 - 25/8/16 at 03:56 PM

quote:

Originally posted by Andy D... I can't imagine how bad it must handle without it fitted.

I have driven a Sylva Striker where the Panhard rod had failed, and whilst easily noticeable and a bit 'loose' at the rear end, it

wasn't as bad as you might imagine, at road speeds. Though the geometry of the Sylva's longitudinal Watts links means that they don't

like moving far, side to side, even without the Panhard rod.

I'm absolutely stunned that this car appears to have gone through IVA and (presumably) MOT without this being picked up, though.

Andy D - 25/8/16 at 04:06 PM

quote:

Originally posted by Sam_68

quote:

Originally posted by Andy D... I can't imagine how bad it must handle without it fitted.

I have driven a Sylva Striker where the Panhard rod had failed, and whilst easily noticeable and a bit 'loose' at the rear end, it

wasn't as bad as you might imagine, at road speeds. Though the geometry of the Sylva's longitudinal Watts links means that they don't

like moving far, side to side, even without the Panhard rod.

I'm absolutely stunned that this car appears to have gone through IVA and (presumably) MOT without this being picked up, though.

I was imagining something that feels a bit like a drift car.. but doesn't actually break traction at the rear!

Sam_68 - 25/8/16 at 04:21 PM

From memory (it was a long time ago), it felt pretty much as you would expect it to: with even a slight change in direction there was an

initial 'flop' and a knock as the chassis moved across to take up the slack against the trailing arms, but then (and as the cornering loads

built up) it felt pretty consistent and not all that unusual.

I only drove it a few miles to limp it home, and not an experience I'd voluntarily repeat, mind you!

I once had a rear suspension bolt shear after becoming airborne at a 3-figure speed in a mid-engined, double-wishbone car, too, and whilst it was a

definite brown-trouser moment when it landed, I managed to drive that about 40 miles home without much trauma, too.

Murdoc - 25/8/16 at 05:06 PM

I emptied my pockets at the steel merchants got home and I have taken the back off to find a number of horrors. Looks like it's going to be a

while before I drive it again.

Murdoc - 28/8/16 at 06:53 AM

I have fitted a Panhard bar. It seems the mounting pointed out earlier by Andy was indeed for the Panhard (although nothing on the chassis side), not

sure why I thought there was one the other side of the axle too. I cut that mount off, welded up the remnants and built new brackets as I wanted a

double shear design. I corrected the handbrake brackets and it all fits nicely. Both rear brake wheel cylinders are leaking so waiting to get them

from ECP and I need to actually attach the roll cage stays to something (air doesn't work well in compression).

Thanks for the help.

adithorp - 28/8/16 at 07:54 AM

Nice bit of work there.

Murdoc - 3/9/16 at 05:32 AM

Thanks, I have done a few other jobs before putting it back together, I was thinking of documenting the improvements in a thread would the project

diaries forum be appropriate for a rebuild thread? Still got plenty to re-do.

adithorp - 3/9/16 at 07:53 AM

quote:

Originally posted by Murdoc

Thanks, I have done a few other jobs before putting it back together, I was thinking of documenting the improvements in a thread would the project

diaries forum be appropriate for a rebuild thread? Still got plenty to re-do.

Sounds as good a place as anyto put it.

.jpg)

.jpg)