handbrake cable question

tom_loughlin - 5/12/04 at 09:41 PM

hi guys,

after having a very productive weekend with the car, im now back in bristol a very happy bunny.

got it turning over this morning - which is a major milestone for me - next stop.... engine runnng properly.

the only goot thing about leaving my car on a good note is that i cant wait to go back home again to carry on - but that will have to wait till xmas

one small problem though....

i got a new handbrake cable (rear discs) and want to avoid shortening it if at all possible - but i cant thread it through the seat-back bulkhead tube

things.

as far as i can see, my only option is to cut the cable, which will significantly reduce its strength.

just wondering what you guys have done, and the best method of securing the cable so it doesnt fail.

cheers guys

tom

indykid - 5/12/04 at 10:27 PM

there seems to be two schools of thought on this.

one is to cut the crimped end off, then re weld a nut/bolt shank on the other end once shortened.

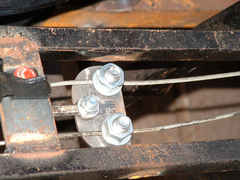

the other is how i've done it

please don't say it'll fail sva cos i might cry. seems stronger than trusting a weld though. it will tow a car happily

b&q warehouse near the steel rope.

tom

Rescued attachment handbrake join.jpg

shortie - 5/12/04 at 10:29 PM

Hi Tom,

Great to hear you got the car going, be driving it soon

I had the same problem and the cable is way too long anyway so the only way is to cut the inner cable and I got an end piece from MK which just screws

onto the cable end, it has two grub screws and seems very strong.

HTH,

Rich.

shortie - 5/12/04 at 10:30 PM

Hi indykid,

SVA man won't see it anyway! It'll be fine.

Rich.

indykid - 5/12/04 at 11:29 PM

i thought top cover had to be removable so if he so desires, he can check everything is sound inside the tunnel, electrics not run with fuel lines

etc.

the mk bit seems like a good idea, but when i did my handbrake, they didn't sell them as such. there was an indy being built in the shop at the

time and i bargained with charlie for some pedal cable ends and top hat adjusters that were in their box in the footwell. no one knew a price and we

ended up going to see martin who said ooooooooooh, call it £15. it's come on a bit since

bloody good kit for the price and grip like a terrier to a shin

tom

tom_loughlin - 6/12/04 at 12:17 AM

snoopy,

do u sell the grub-screw end things for rear disc brake setups? (like rectangular eyelets) ive seen the top hat things for drums, and they lok

great.

how much are they if u sell them

thanks for your help

tom

Petemate - 6/12/04 at 09:37 AM

Hi Tom (Indykid)

The clamps should be fine. I know of at least one RH builder (like me an ex-RAF aircraft engineer) who passed SVA with this method, and the join was

seen and approved by the inspector.

AFAIK, it should be OK providing Mr SVA can apply Incredible Hulk forces and not make it slip.

That said, I shortened mine by the time-honoured method of drilling a piece of M8 bolt, whacking it on an anvil with a cold chisel and putting a spot

of weld on the end wiv me MIG. It has so far resisted my Hulk impressions.

HTH

Petemate

splitrivet - 6/12/04 at 10:03 AM

Ooooooh adjusters ,what Ive been scavenging the scrappy for months for (to no avail).

Cheers,

Bob

David Jenkins - 6/12/04 at 10:40 AM

quote:

Originally posted by indykid

i thought top cover had to be removable so if he so desires, he can check everything is sound inside the tunnel, electrics not run with fuel lines

etc.

My inspector just looked up the tunnel from both ends when the car was up on the hoist - I had a look as well, and you can see just about everything

(my floor extends across the base of the tunnel).

David

stephen_gusterson - 6/12/04 at 11:02 AM

i have done the same as indykid

But i used about 5 clips.

you can buy them from homebase.

atb

steve

tom_loughlin - 6/12/04 at 11:39 PM

cheers guys - looks like a quick trip to homebase is on the cards - when its fitted, it means i can roll it around the yard - and stop it when its

going too fast!

it could even drive under its own power (allbeit that of the starter motor , but hey, we've all gotta start somewhere!)

, but hey, we've all gotta start somewhere!)

thanks again

tom

stephen_gusterson - 7/12/04 at 12:23 AM

i found that when i rolled mine out under power, even tho i knew the brakes didnt work, you still went for the pedal than the lever!

make sure your co-ordination is right!

atb

steve

ps

my local homebase has the clips next to the 'cut to length' ropes, hose, etc

907 - 7/12/04 at 01:04 AM

I did the old 8mm bolt bit. (Oldgitpete)

Crimped them on with a set of bolt croppers with a notch cut in the jaws.

Splayed out the ends and silver soldered them. (belt & braces)

Took the test piece to work and fixed one end to the 8 tonne surface bench,

the other to the overhead crane, with a digital weight gauge in line.

It broke at 330 kgs.

With two cables on a handbrake, I should in theory be able to lift the whole car

off the ground by these cables. Oooerrr

Paul G

[Edited on 7/12/04 by 907]

stephen_gusterson - 7/12/04 at 10:56 AM

whats more important is the mechanical advantage of the handbrake - you need to quantify the tension pulled on the cable by whats in effect an

amplifying lever (handbrake handle) rather than a static weight.

600+ kilos might be a good hard pull perhaps.....

atb

steve

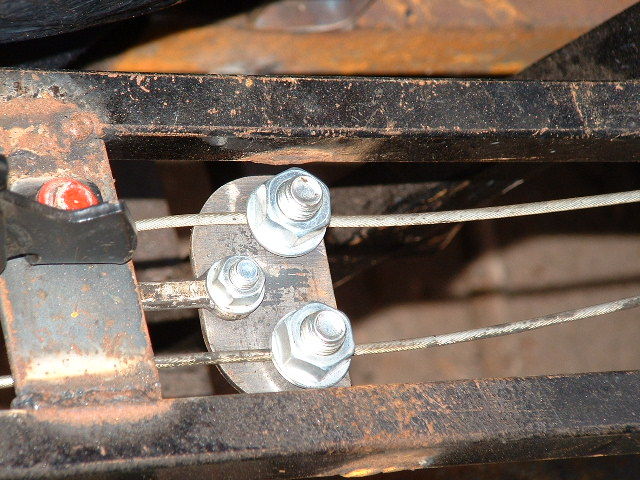

dblissett - 7/12/04 at 01:30 PM

i am planing to try this

the large bolts are m10 with 3mm holes drilled for the cables

the back plate will be supported above the plate when i weld it in

ps the cable will be changed for a new one but i plan to use a adjuster of the old cable and one off the new

has anyone else done it this way and got passed the sva

Rescued attachment hand brake.JPG

dblissett - 7/12/04 at 01:32 PM

Rescued attachment handbrake.JPG

, but hey, we've all gotta start somewhere!)

, but hey, we've all gotta start somewhere!)