[Edited on 27/6/13 by PhillipM]

The anti roll bar on my 3 wheeler isn't stiff enough for the job and there's no simple way to modifying it, so I'm thinking of making one. 25mm tube with a 3mm wall is 80% stiffer than the 17.5mm solid bar I currently have and also a bit lighter. If I buy a bit of seamless tube from the shop and weld arms to it, will it be OK or do I need special steel for the job?

Worth a try - so long as the tube is not the annealed gas pipe version.

It should act as a spring if you do not get near the yield point.

Ant roll bars are solid bars acting as torsion bars, tube is no good for that.

Without doing the maths I would guess a 25mm hollow bar is more than 80% stiffer in torsion than 17.5mm bar.

quote:

Originally posted by coozer

Ant roll bars are solid bars acting as torsion bars, tube is no good for that.

quote:

Originally posted by coozer

Ant roll bars are solid bars acting as torsion bars, tube is no good for that.

quote:

Originally posted by PhillipM

quote:

Originally posted by coozer

Ant roll bars are solid bars acting as torsion bars, tube is no good for that.

Tube is fine for that. And it's lighter.

It would need to be a pretty long bar for CDS tube to work, however, I've made a few out of T45 before. Saying that, you can buy EN24T in rod and just use that to make a solid bar anyway.

You do have to be careful with the joint design and welding if you weld arms on, as you'll soften the material at the sides of the welds, so it may just twist there.

[Edited on 27/6/13 by PhillipM]

I've seen people use allsorts of s**t over the years, including a bit of threaded rod, they all claim it works fine until you take it off and

it's full of stress marks where it's been deforming instead of just flexing....

[Edited on 27/6/13 by PhillipM]

Why not? Prop shafts don't seem to mind?

quote:

Originally posted by coozer

Ant roll bars are solid bars acting as torsion bars, tube is no good for that.

Pick up a Caterham ARB, thick wall hollow tube, google "second moment of area", makes it better harder to twist so you can build smaller

and lighter  that's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

that's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

Regards Mark

if you u2u me your email address, I will send a spreadheet of tube vs solid stiffness realitive to external diameter and weights

sorry cant resist.

That famous quote:

It's better to remain silent and only be thought a fool than to speak and remove all doubt

quote:

Originally posted by mark chandler that's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

If welding is a bad idea the next alternative is to get some 19mm bar, heat it with a blow torch and bend it in the vice. Would this be a better idea?

My physics teacher must have been telling lies then, he explained it so well

Caterham ARB is still hollow tube never the less

Nah, it's right for an arb where you want maximum stiffness/weight.

It's just for halfshafts, if you go with the lowest stiffness/strength you can get away with (usually that means solid shafts with very high

strength material), the shaft will absorb a lot of the shock loadings that would otherwise go through the drivetrain.

quote:Because its cheaper, and they have to be fairly small diameter either way round?

Originally posted by PhillipM

Mine are solid, deliberately!

I wish they were cheap.

quote:

Originally posted by PhillipM

I wish they were cheap.

Propshafts are hollow because a solid shaft would bring with it major vibration problems.

quote:

Originally posted by smart51

If welding is a bad idea the next alternative is to get some 19mm bar, heat it with a blow torch and bend it in the vice. Would this be a better idea?

quote:

Originally posted by Slimy38

quote:

Originally posted by smart51

If welding is a bad idea the next alternative is to get some 19mm bar, heat it with a blow torch and bend it in the vice. Would this be a better idea?

When I was looking at roll bars for my tin top, one of the top selling points was that they were cold drawn/mandrel bent or similar words that don't actually make sense but generally imply no heat was involved. Without actually knowing the physics behind it, wouldn't heating produce a similar effect to welding?

The other thought I had was that you could use some sort of mechanical fixing. Along the lines of the old Peugeot 205 suspension torsion bar, the end of the torsion bar was splined and the trailing arm fixed on it that way. Could you apply the same principle in a roll bar?

(Of course, I'm very conscious of Hector's post, so I'll say straightaway that these are just me thinking aloud and I have absolutely no idea whether they're actually true/helpful/safe/stupid/dangerous etc)

[Edited on 28/6/13 by Slimy38]

quote:

Originally posted by mark chandler

Pick up a Caterham ARB, thick wall hollow tube, google "second moment of area", makes it better harder to twist so you can build smaller and lighterthat's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

Regards Mark

quote:

Originally posted by onenastyviper

quote:

Originally posted by mark chandler

Pick up a Caterham ARB, thick wall hollow tube, google "second moment of area", makes it better harder to twist so you can build smaller and lighterthat's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

Regards Mark

OK, for the same modulus and diameter material, which would have the greatest torsional rigidity, a tube or a solid bar?

quote:

Originally posted by britishtrident

quote:

Originally posted by onenastyviper

quote:

Originally posted by mark chandler

Pick up a Caterham ARB, thick wall hollow tube, google "second moment of area", makes it better harder to twist so you can build smaller and lighterthat's why gun drilled half shafts are better than solid, the materials are just more expensive or need more work.

Regards Mark

OK, for the same modulus and diameter material, which would have the greatest torsional rigidity, a tube or a solid bar?

Easy using the Principle of Super Position -- ie in the maths you take away the it that isn't there.

Using basic torsion formua to find the stiffness of the hollow shaft just work out the stiffness of the solid shaft minus the stiffness of the bit metal removed to make the hole.

Obviously it works out the hollow shaft is less stiff but there isn't any where near as big a difference in torsional stiffness as a lay person might expect, usually by going up a very small step in both diameters the hollow shaft can be made both stiffer and lighter..

quote:

Originally posted by nick205

quote:

Originally posted by PhillipM

I wish they were cheap.

Sorry to hi jack, but I like the buggy! Is it a custom build or designed for a race series? Where do you use it?

quote:

Originally posted by onenastyviper

Thanks - I was getting a bit worried with my understanding. I have had this argument before with someone who suggested that a hollow tube is stronger than the equivalent solid tube.

I suppose, like anything in engineering, there is a compromise to be made between wall thickness, torsional strength and buckling.

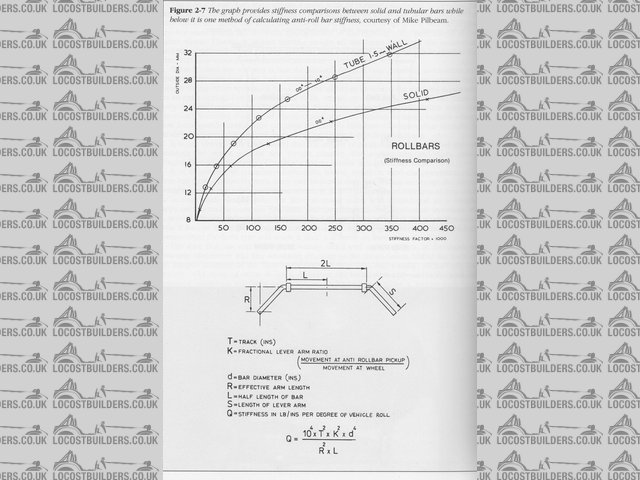

From Allan Staniforth's Competition Car Suspension:

ARB stiffness formula

Westfield's effective ARB is a length of CDS with ends welded on to it, works wonderfully.

My widetrack Westfield solution was to extend this bar with a section welded into the middle. It worked beautifully on the track, raced ruthlessly.

Whatever the nannies say, just get a length of tube and go play.

quote:

Originally posted by PhillipM

I might stick a thread up, just didn't seem like quite the right place for a build thread

It meets that, I'll stick a thread in Maintenance and Mods later on.

Seamless tube is pricey isn't it? The new bar is made, painted and this evening it was fitted. The standard 'stand on the sides of the chassis and wobble from side to side' test shows that it is a lot stiffer than the Fiat bar, though bouncing on one side of the chassis shows that it does allow one side of the car to move independently of the other. The lesser known 'put your foot on the rear wheel and hang off the roll over hoop test shows that the car now hardly leans at all. This, I hope, will put an end to all that pesky body roll.

Seamless is cheap, you want to try having a car built out of T45