thanks in advance for any comments (except comments of 'thick twat', these wont be appreciated...!)

it the front roll centre on a book chassis any good? im thinking of copying the dimensions into another design. would there be any easy improvements

if i have an ARB to help keep it level?

thanks in advance for any comments (except comments of 'thick twat', these wont be appreciated...!)

The book roll center is about 3-1/2", maybe a little high to go with your IRS, which often have lower RCs.

Suggest you determine where your rear roll center is, then see about putting the front one somewhat lower.

Give me a holler (U2U) if you'd like a hand doing some modelling.

Pete

The book geometry is fair but there is room for improvement. Also it will only work well with the Cortina upright so if you plan to use another

upright you should redesigned it.

Cheers!

"Complete and utter BULLSHITE"

Syd - I'm sure thethread was only started 'cos we hadn't wound you up lately ;^)

Now.. No bl00dy swearing boys.......

Bob

quote:

Originally posted by Syd Bridge

Heeeeere we go again!

Roll centres. Complete and utter BULLSHITE!!

Cheers,

Syd.

tescos

thats my roll centre

atb

steve

just ask, im full of good advice like this. Syd isnt the only person to have that opinion.

Why are roll centres bollox?

my take on it is unless you are going to race competitively, then does it really matter?

A further take on it, is are you going to be able to make something at home thats better than 40+ years of cateringvan development?

At the end of the day, most of us are amatuers. The more you deviate from the base design without knowledge, the more likely you are to f&*k it

up.

Again, in 4+ years I have never ever once at all, in the slightest, seen anyone post

'my locost handles like shyte - how can i make it better'.

KISS

atb

steve

get some mitchell software , and do your own , it doesnt take much , what it will show up are things like toeout/in on turns and roll etc , so you can

eliminate as much of that as possible .

trying to keep a good position on roll centre will have the same meaning as not leaning the spring damper units over at 45 degrees aswell .

i quite see your point syd. completely agree. i put my thinking cap on and worked it out anyway, most of the uneven length stuff and the

unparallel-ness is to keep the wheels upright in different situations, i think i will use a big ARB and make it more simple.

Sorry Syd, just remembering it seemed to get a bit personal last time which detracts/distracts from what's potentially an interesting topic.

My personal experience of home-made IRS designs is a single vehicle I built 12 years ago when there was no www & I just guessed at pivot locations

& the result seemed to work just fine. The internet has given me access to slightly more information (a little information is a dangerous

thing????) so with the locost I'm building now I used "roll centre" software to help determine where to place the pivots. Will it be

any better/worse - I don't know yet (and probably ain't good enough a driver to be able to tell ) but for the time being I fell happy that I

can justify every dimension of my suspension on the basis of at least "something"!

Also I'm sure that there are many ways of "skinning a cat", this system seemed to work for me. I appreciate that the important thing is

to keep the outside wheel vertical in turns - that's a direct quote from late fifties colin chapman.

Re Steve's point about the lack of threads "my locost handles shite", it may be that a lot would - if the suspension weren't so

hard! I've had a go in a few now & generally the ride is so hard that at 60+ on normal roads the car is bouncing off the road a lot of the

time & you can't see properly! (OK I'm old & soft, there must be others out there...)

I'm not trying to stir it, just pointing out the alternative view that the roll centre bobbins has its merits!

When my car's on the road I'll find out if handling is one of them! I feel reasonably confident!

Cheers

Bob

Just for info

Standard Caterham Deon

front 60mm

rear 120mm

Experimental Indy Caterham

front 30mm

rear 65mm

Elise

front 30mm

rear 75mm

If you're going to build it yourself why not build it right? Put the roll centres in the best position. If they don't matter much then this

won't hurt. If they do matter then you'll get better handling.

Syd, please tell us why you think roll centres are wrong.

quote:

Originally posted by cymtriks

Syd, please tell us why you think roll centres are wrong.

hello syd my car handles like poo cos its been in the garage on stands for the last 8 months while i have tried to sort out this very sort of crap

its never been on the road yet and yes i agree that the more we go off book the more problems we make for all us home builders

on balance tho with pbura's help i now have a rear irs i feel more confident about taking on the road and i suppose thats all that matters

dave

quote:

Originally posted by dblissett

on balance tho with pbura's help i now have a rear irs i feel more confident about taking on the road and i suppose thats all that matters

quote:

Originally posted by Syd Bridge

I am saying no more.

Cheers,

Syd.

It seems pretty obvious to me that the location of the roll center wrt the COG is going to determine the amount of body roll under any arbitrary condtions and hence the amount of camber change. Do you not consider camber change in roll important?

surely, roll centre is down to pick up points on the chassis - if what I read here is to be believed.

I know bugger all to make a tech argument.

My one observation is :

using given hubs, with a given ride height, surely where you mount the pickup points is pretty much fixed for you?

If the hub lower joint is say 150mm from the ground, and you want a 150 high level lower 'bone its gonna be fixed 150 from the ground. Same for

top bone.

Unless you have so whacky wishbone angles.

I think some times that people take car building way too seriously. Its been done for 40+ years to this design, and there are loads on the road. Its

not F1. Many people seem to sell their cars in less time than they take to build em!

atb

steve

[Edited on 5/10/04 by stephen_gusterson]

Yo Steve,

yeah the hub end is determined by what hubs you use, but at the chassis end you have about a square foot in which you can design your pivots to go

anywhere you want! Who says the lower wishbone has to be level? It's one of those general rules of thumb, that and "make the top wishbone a

bit shorter". Then you worry about vertical separation at the chassis - make this a bit less than at the hub so your camber change in roll is

sensible (nb tiger avon rear doesn't do this). you're still left with a large area of uncertainty - maybe it doesn't matter? The

software is free off the web & easy to play with - what's to be lost by using it???

It's certainly easier thanresorting to string (string computer - was that in Staniforth's book?)

Syd - I know you weren't going to say any more (teehee :^) but honestly I'd be interested to know the system you advocate. Previously

you've said (I think, paraphrasing) "consider what's happening to the outside tyre" - which is a bit esoteric, a somewhat more

detailed procedure would be appreciated.

Cheers & beers

Bob

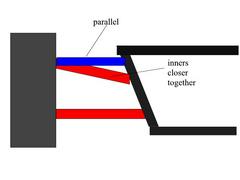

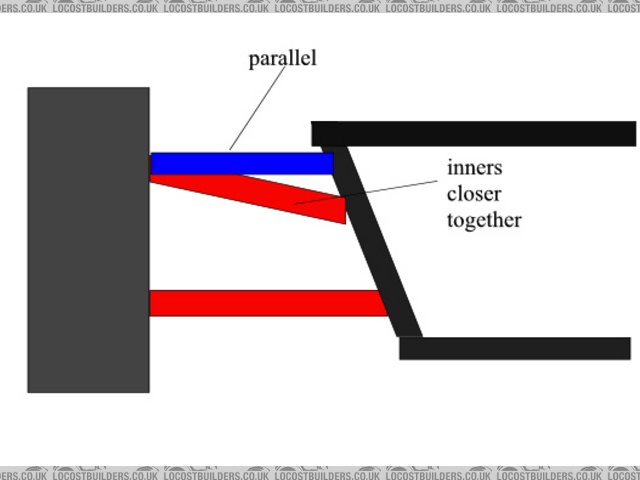

Hi Sid what do you mean by "bring the inner pivot point a bit closer together as the outer pivot points?

Aha - got your reply in while I was writing my post

cheers

Bob

I think the inners closer than the outers gives you better camber control on the outside wheel when cornering so you can keep the tyre flat to the

road. That's my theory and I'm sticking to it. I don't worry about things I don't understand, but I don't deny their

existence. Roll centres, fairies, Bigfoot, air and the Holy Grail are all things I think about occasionally but I don't get too wound up about

them.

Rescued attachment wishbonepos.jpg

I second Bob C's observation: Who says the (front) lower wishbone has to be level?

If you have the oportunity to optimise roll centres why not take it?

If the inner end of the lower wishbone dips down even one degree, then the front RC will be below wheel centre height which has to be a good thing,

especially if the car has a live rear axle.

And Syd, does "Make them as even in length as possible." mean they should be equal length if possible? I don't think even you would

believe that. Pick your words more carefully, because there are people here who take a lot of stuff as gospel.

Sure you can make a system that has equal length and/or parallel wishbones and it may make some folk happy enough, but quite simply it isn't

going to perform anything like as well as a properly designed system.

Sid, you have thus far given no reasons for your belief that roll centers are "bunk", yet I have several books in front of me given lots of

reasons why they are important. Would you like to expand on your side of the story a little?

To echo a common sentiment (from a different perspective):

If the tires and pivot points have no compliance, there's no doubt the vehicle will roll about the virtual roll center. The roll center can (and

often does) move, so this is not a static calculation.

Tires and pivots do have compliance, so the calculations are at best an approximation. It's risky to think that, with the analysis tools and

build tolerances most of us have at our disposal, we can design our suspension system (geometry, shocks, springs) with pencil and paper to have it

perfect the first time (ignoring for a second there's no such thing as perfect, only compromise). We hopefully can get close enough that the

adjustability we build in can do the rest.

I've never heard of a serious manufacturer that designs, builds and ships without a test cycle. To be absolutely sure this needs to be done on a

track at the limit of adhesion. While our cars may handle better than anything we've ever driven, many of us street drivers will not find out

what happens at the limit until it's too late. Finding out there's trailing throttle snap oversteer in a panic situation on the street can

be pretty deadly...

I've had to make changes (NA builder), but I try to stay as close to the original design as possible for this reason (not that I'm

comfortable Champion did all of this testing, but I'm sure he's done more than me).

Like Hugh I was confused by the assertion that wishbones be equal length. I thought it only make sense for high performance cars with virtually no

roll (F1?), as it keeps the tires better positioned under braking (front) and acceleration (rear). But I am willing to learn  . Please share Syd

. Please share Syd

.

.

Thanks for the explanation Peteff but as Sid said" keep the lower wishbone parralel to the ground and the upper wishbone parrarel to the lower" how can Sid mean that the upper wishbone is angled up?

set the upper parallel to the lower,or bring the inner pivots a little closer together. English may not be your first language but the little word 'or' is the one that makes the difference. Do you speak French, if so it's 'ou'.

Im looking forward to syds reply

atb

mr fence sitter

equal length wish bones?

syd i mainly agree with what you are saying but i was told a good rule of thumb was to have the top whisbone 2/3 the length of the bottom wish bone

and not to have both wishbones pararel

also the pivot point centers at the wheel end of the wish bones should be slightly more than at the chassis location points

i think that's what you are saying

ps if my irs is still wrong its staying that way or my car will never make it to the road

dave

[Edited on 5/10/04 by dblissett]

I did similar, but drawn out on wallpaper in higher and lowest positions.

still screwed up tho cos I measured pivot points at the extremities of the hubs, and not at the actual ball pivot centre.

had to make the whole fffing front suspension again.

Thats why im an advocate of dont play with stuff you are not sure about, when it works as is...

atb

steve

I have no idea where my roll centre is, I just want to drive a car. If it handles like a typical saloon, i will cisider it a success. Im no racer, and

neither is my car!

[Edited on 6/10/04 by stephen_gusterson]

Sorry Peteff,i do understand the word "or"

'just was temporary reading what i wanted to read if you know what i mean.

The French word "ou" means nothing to me as i'm Flemish but i know the Flemish equivalent which is "of".

[Edited on 6/10/04 by Cita]

i think we might of found syd's roll center

dave

quote:

Originally posted by Syd Bridge

(I think the hallowed Mr.Staniforth even describes this in his books.)

quote:

Originally posted by Syd Bridge

Ok you lot, listen up, just for once!

1..As I put before, the opinions I put are not only my own, but also those of a couple of well known designers.

2..You don't have to 'do as I say'. I just offer what little help I can, and try to lead in a safe and relevant direction. You can 'Go Your Own Way', as Fleetwood Mac sing.

3..You can believe what you read in books, or use your own brains. (But if you believe what's written in books, give up your build now, because the world is going to end tomorrow. I know, I read it in a book.!!)

Cheers,

Syd.

Now, back to work so I can get home for the weekend.

quote:

Originally posted by Syd Bridge

Like a beasty that won't flush..it just keeps coming back...............

I've said nothing that I know to be untried or untested, and not in current use.

Syd's challenge led me to do a bit of research about roll centers (on my lunch hour  ). He is right about the geometric roll center model being

considered obsolete in some circles. The newer methodology is to determine roll centers in the lab or at the track using fancy data acquisition

technology that takes into account compliance in suspension components.

). He is right about the geometric roll center model being

considered obsolete in some circles. The newer methodology is to determine roll centers in the lab or at the track using fancy data acquisition

technology that takes into account compliance in suspension components.

He is, however, wrong about roll centers being unimportant. Roll center height DOES determine body roll, and also how much vertical jacking force is

generated by the suspension links. These both affect the tire contact patch.

Interestingly, the old (but new to most of us) geometric models can still give good results. A couple of enlightening discussions:

http://p081.ezboard.com/fdsrforumcarbuilding.showMessageRange?start=21&stop=40&topicID=420.topic - Please note contributions by Jay Novak

(vehicle dynamics specialist with Ford and former head of their NASCAR program).

http://www.auto-ware.com/ubbthreads/showflat.php?Cat=&Number=489&page=0&view=collapsed&sb=5&o=&fpart=1 - Using Ortiz's

rule of thumb of 75% of loads being generated by the outside wheel, the recommendations of Staniforth and Smith for controlling the RC laterally make

sense. With a centrally located geometric RC, the force vectors are at equivalent angles so that the force-based roll center is about the same height

as the geometric roll center.

Syd's recommendations for parallel or near-parallel wishbones put the RC at ground level where force vectors are near horizontal. Because of

this, jacking is not an issue.

The parallel-ish wishbones would work well for a race car set up with, say, 3 degrees negative static camber, because the camber on the inside tires

would never go positive. Grip would be fine throughout the range, because racing tires can function well with large amounts (5+ degrees) of negative

camber. Us hoi polloi would never put up with the tire wear.

This setup would be crap in a road car running -1 degree static camber.

I wasn't previously aware of the jacking forces caused by wishbone suspensions with high roll centers. This explains why IRS cars, such as the

Elise and the new Caterham, have such low roll centers. Solid and de Dion axles have horizontal load paths, so do not have this problem.

Pete

quote:

Originally posted by pbura

The newer methodology is to determine roll centers in the lab or at the track using fancy data acquisition technology that takes into account compliance in suspension components.

. Maybe I missed my calling

. Maybe I missed my calling  ?

?

quote:

Originally posted by JoelP

thanks in advance for any comments (except comments of 'thick twat', these wont be appreciated...!)

quote:

Originally posted by MikeP

Another argument and this one is all

well , if maclaren and such F1 teams still use roll centres well below ground level to give there drivers some feeling of roll weight transfer , and

making the car more driveable we shouldnt dismiss the idea of them .

And if we all use the mitchell software that uses forces to compute roll centres then well all get along .

Ay up, I feel a twenty pager coming up now no biting or scratching of eyeballs ladies

Cheers,

Bob

I have no idea where my roll centre is,

You'll make your mind up in a bit Steve. My wife's started baking ours, they're really good. We call them cobs round here though.

quote:

Originally posted by Syd BridgeAnd leave things at that.

quote:

Originally posted by Peteff

I have no idea where my roll centre is,

You'll make your mind up in a bit Steve. My wife's started baking ours, they're really good. We call them cobs round here though.

quote:

Originally posted by Cita

The French word "ou" means nothing to me as i'm Flemish but i know the Flemish equivalent which is "of".

[Edited on 6/10/04 by Cita]