Rescued attachment piperuns.jpg

Anyone know what the SVA requirements are for free runs of brake and clutch pipe. Will this be ok

Rescued attachment piperuns.jpg

longest unsupported length for brake pipe is 300mm maximum. Looks like your length is significantly more than that....

Clip it inbetween to escape the rejection slip!

All you need is a slightly tighter bend at the top and then clip it once to the vertical surface on the way down. Shouldn't be a problem.

Cheers,

Craig.

Myself I'd put a small angle bracket onto the cylinder mounting bolt and a P clip to that, It needs something.

ATB Dan

Thanks guys, I thought it would need another but I was hoping to get away with not having it screwed to the pedal box. The clutch which you see is not

the real problem though, it's the 2 brake lines which exit from the other side, it's a confined space and it's going to be a bugger to

get a clip in there.

Never mind, at least I know 300mm is the magic number.

Cheers!

my car failed sva for a 160mm unsupported length, this was along a straight tube and fitted with plastic p clips. I also failed as you may for running

a brake lin close to another component without iversleeving it to avoid abrashion.

Whatever your opinions are, the best bet when doing SVA is to do whatever you are told..........

quote:

Originally posted by stressy

my car failed sva for a 160mm unsupported length, this was along a straight tube and fitted with plastic p clips. I also failed as you may for running a brake lin close to another component without iversleeving it to avoid abrashion.

Whatever your opinions are, the best bet when doing SVA is to do whatever you are told..........

The SVA manual is for guidance only according to the VI, if the tester deams an item to be of noncompliance he may do so legitimately.

In my case the issue was that i had done it inconsistenly with other areas. i.e. i had it supported every 80mm or so around a particulary region to

reduce vibration of a strange shaped run and it was decided i should have done this everywhere else!

I used a length of trimmed plastic pipe over the line where things ran close, the line does not rub on the tube but the tube may rub on the closest

other part.

quote:

In my case the issue was that i had done it inconsistenly with other areas. i.e. i had it supported every 80mm or so around a particulary region to reduce vibration of a strange shaped run and it was decided i should have done this everywhere else!

I wont tell you about the steering whell problem then

quote:

Originally posted by stressy

I wont tell you about the steering whell problem then

I purchased a "SVA" compliant steering wheel from a reputable manufacturer. A wheel i know passed on a friends car. On my car i have it

mounted on a 3inch extention to get it where i like it but for sva i mounted it as syandard. This left around 40mm between it and my knees.

At the SVA one of the inspectors commented on "oh youve got that wheel" and suggested i should be using a standard ford one. It then took

him the best part of 30 mins to measure every feature in order to determine 1 radii to be 0.1mm (approximately) below the minimum, this was where the

edge was deformed through te dishing process.

The car failed. I went back with the sierra wheel fitted, which meanmt i had to slip the clutch the hole way there as i could not take me foot off hte

pedal cos the wheel was in the way.

When i asked if this was sane, how can i drive the ca like that the comment was something along the lines of "we are not testing whether you can

drive the car sir"!!!!!

Anyways passed test drove it outside fitted the other wheel and drove home. As i said before, just do what they tell you andyoull be fine. ( No matter

how bonkers it may be)

Skirrow,

Please don't take what I say the wrong way, but...

One thing that will impress the SVA man is a neat and tidy layout (the bullshit factor). No matter how safe your installation is, it doesn't

look tidy, so the inspector will pay closer attention to it.

The neater it looks, the more relaxed the tester will be.

Advice offered in the best of intentions!

David

quote:

Originally posted by David Jenkins

Skirrow,

Please don't take what I say the wrong way, but...

David

Id agree with the make it look neat 100%. The SVA man was very impressed by fusebox installation, seatbelt mounts, headlight mounts and handbrake etc purely because they looked neat, he commented on my fabricated turret mounts for the belts manytimes, cmoparing them to the normal gobbed on bit of tube.

quote:

Originally posted by Skirrow

Possibly a stupid question, byt what can I do to neaten it up? I though the pipe looked ok!

Ok, well before I start changing how they are near the pedal box I had better let you guys tell me whats wrong with the long runs. I prepared to buy

new pipe and start again so feel free to be harsh!

My main questions are....

- Are they neat enough?

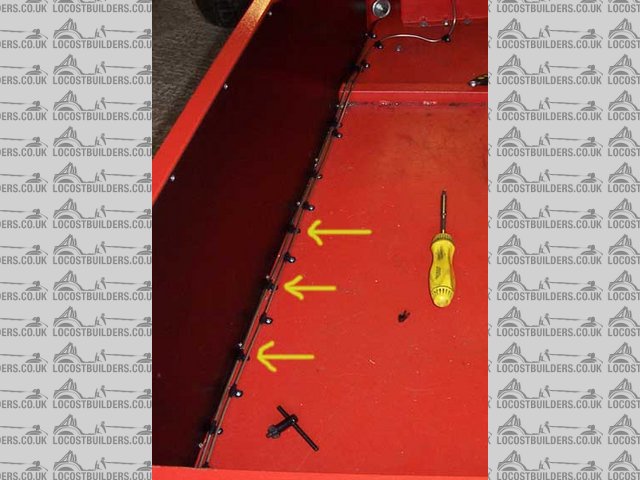

- The yellow arrows point to where the clutch pipe runs over the brake pipe clips. The clutch pipe actually touches the screw though. I did it to make

it look neater (!) and keep it compact but is this going to be a problem? And should I move the pipe (I could reverse the clips but use the same hole)

Or should I tape over the screws or round the pipe.

- Anything else I should be aware of?

Rescued attachment piperuns2.jpg

PS. My pipe bender only does the large sweeping bends that you see in the 1st picture. Is it possible to get (a cheap) one that does tighter bends.

And also I had a right bugger of a time getting the coil of brake pipe any where near straight, any tips in this?

And.....

The pipes are single pipes that go from the master cylinder along the floor, through the rear bulkhead and straight to the cluctch slave cylinder, and

from the brake master, along the floor, through the bulkhead and to a 3way before shorter runs to the brakes. Am I better using several short runs

rather than one long run? 1 long seemed better before I started but it is less manageable and difficult to get bend in the right place and so on.

And..... you should never start a sentence with "and"

Cheers,

Dave

Are those pipes in the passenger space? If so, you'll need to box them in to protect them from damage. On a bog-standard Locost the pipes can

easily go in the transmission tunnel. Otherwise they look fine, as long as the pipe isn't actually touching (or likely to touch) the clips

underneath.

As for benders  , you can get a hand-held jobbie that will gve you radii down to 25-30mm, if that's what you need. Fairly cheap, too!

, you can get a hand-held jobbie that will gve you radii down to 25-30mm, if that's what you need. Fairly cheap, too!

rgds,

David

[Edited on 24/9/04 by David Jenkins]

Yes the pipes are in the passenger compartment, it's not a locost, it's an off-road buggy with a flat bottom so I didn't want them

underneath where they will get ripped off.

The clutch pipe (on the right) touches the screw heads which hold the brake pipe clips in, I take it that I will have to do somehing about this?

Any ideas about the best way to box them off, I thought it would pass the SVA without boxing them off so I was gonna sort that after the SVA just for

cosmetic reasons.