Optimal setup

Digger Barnes - 5/5/04 at 06:57 PM

As some of you may have noticed I have been working on a suspension geometry simulation program. This has been to teach myself how it all works. I am

now fairly happy with the outputs from the program and I think I am now ready to actually begin to use it to help me design my suspension for the

front and rear.

So now has come the time to ask some questions from the oracle of knowledge that is locost builders.

So here it is: I am intending to use my locost in RGB cat C racing and a little road use (with different bell cranks for the inboard suspension to

raise ride height and reduce effective spring rate). So what I need to know is what am I looking for in terms of camber change in bump, droop, roll

and combinations thereof for racing and the road (my primary concern is to set up for the track with acceptable handling for the road by changing the

above mentioned settings along with static camber).

Please Please Grovel Grovel I need help then I can continue with my design.

Cheers

Gareth

stressy - 6/5/04 at 06:20 AM

Dont mean to state the obvious but if i understand your question corectly then the answer is zero in all cases.

No really, you will set the suspension static geometry for running straight based upon the type of tyre you are using avon vs. yokohama etc. (is thre

a control tyre?)

This setting should be ideal for optimising grip, self aligning torque and spring rate.

Any deviations from this will change the ideal tyre patch profile. This is yet another factor that must then be taken into account.

On a practical scale there are mechanisms such as the Dax camber compensation system and the Radical Nik links which try and minimise camber change by

floating links but otherwise you just have to deal with it as best you can.

At the most basic level work out the maximum camber the tyre can live with and design your suspension so that the set up you have will only go to this

state at the most adverse loading expected during racing and set the static appropriate to that.

I havent spotted your other posts yet on suspension design, are you using special wishbone geometry as well???? what rear end are you going for???

Digger Barnes - 6/5/04 at 07:54 AM

Cheers stressy.

I believe the control tyre will be the Yokohama A048R for the class I am looking at. If you have any information on the tyre charachteristics for this

I would be interested. I suppose I should have a hunt around and even give them a call to see what info I can glean.

Yes it would be nice for 0 camber change most all situations. What Iwould like to know is how well have others managed to design their suspension for

camber change.

Obviously it is a trade of between better camber in roll or bump/droop, but would I be better off optimising roll more than bump/droop as the tracks

should be way flatter than the road?.

As to the rear end of the car it will be IRS with inboard shocks driven with either a push or pull rod (undecided on this yet, but will do a lit

survey and an analysis to see what is best for my situation)

stressy - 6/5/04 at 09:00 AM

Dont forget bump means brakes unless large amounts of antidive are present, and lots of antidive means massive understeer if you touch a rumble

strip.

Also at the rear dont forget about antisqaut.

You need to comprimise for acceleration, braking and cornering.

If your running a light car you may also want to look carefully at unsprung mass, i would personally go live axle rear end and rocker arm front.

Digger Barnes - 6/5/04 at 10:05 AM

Live axle mmm. I already Have a sierra LSD etc hence the IRS (I know dedion is possible).

As to car weight it will be as light as possible. I am aiming for around 400Kg (maybe a bit more depending on roll cage design) the race minimum

weight is 530Kg so I should be able to ballast the car to help with weight distributions.

I will mill the uprights from aircraft grade billit aluminuim to keep the unsprung weight to a minimum and use alloy calipers (again still undecided

whether to use bike units with bike rear discs).

Yep I agree it is a whole can of worms and as I don't have the track experience so I am having to rely on other peoples.

But what I do have is the ability to model the car as well as I can (own software, CAD, Ideas and Nastran). So I hope with input from experienced

individuals I hope I can come up with a car that handles reasonably well.

[Edited on 6/5/04 by Digger Barnes]

britishtrident - 6/5/04 at 02:44 PM

It is a can of worms very often a car with all the wrong suspension geometry can a have brillant handling and set fantastic lap times --- just look at

the lap times a Davrian can with swing arms on the front and semi-trailing arms at the rear. In the case of Locosts I strong suspect that most cars

are set up so stiff that geometry dosen't matter much and much the same can be said of unsprung weight.

Part of the reason for this is since the original Lotus Seven S1 tyres have got broader and the aspect ratio lower so increasingly any change of

camber will reduce the grip so much that the suspension has to be set up bone hard to prevent any significant roll, squat or dive.

pbura - 6/5/04 at 09:31 PM

Gareth,

Didn't know you were going for an ultralight!

I'm pretty sure that the very lightest option is a solid axle, depending on which one you buy. Isn't the Escort axle (per the book) only

about 100 lbs.?

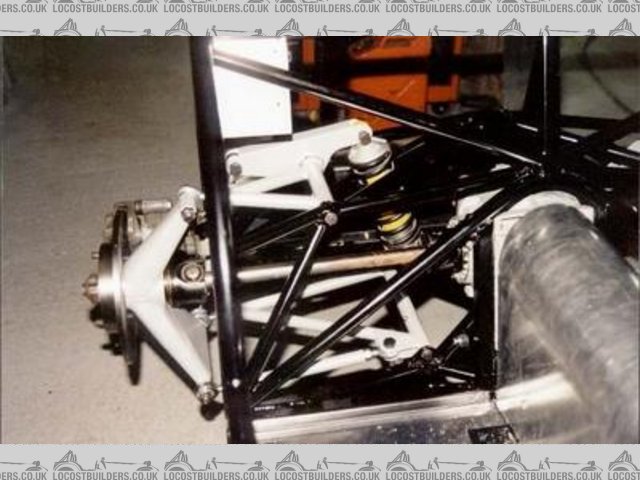

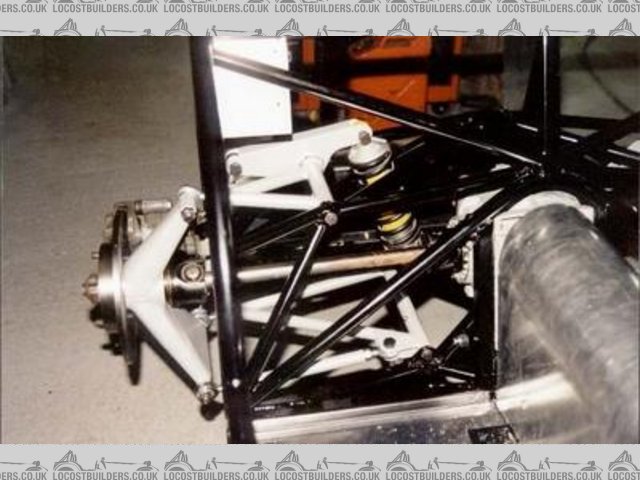

Not to dissuade you; I'm doing an IRS with inboard shocks, more so I can use the shocks than save any weight. I'll be patterning the rear

much after the Leitch (more pics in my archive):

IRS w/ inboard shocks

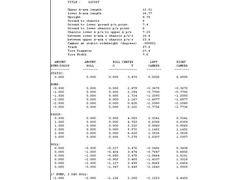

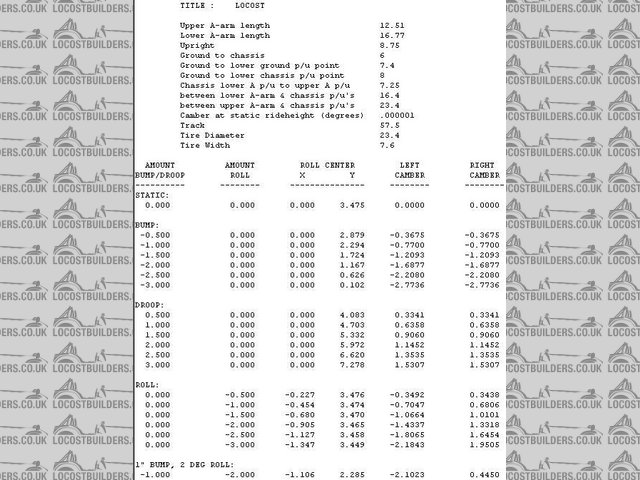

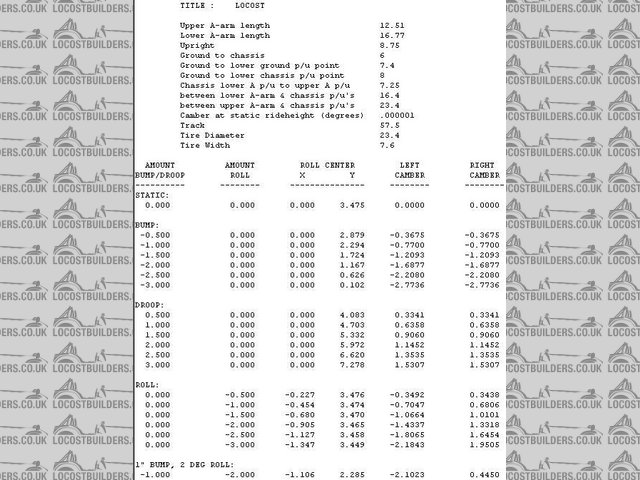

You may have noticed already that when you shoot for perfect camber control in bump and droop, the roll camber goes to hell, and vice versa.

I've found that camber control is pretty much a function of swing axle length. Short SALs give excellent results in roll, and long ones are

better in bump/droop.

The Locost has a SAL of about 80", which would be considered to be on the short end of moderate, I think. I believe the Locost is a good

compromise design, and would be a good benchmark to measure your design against.

MikeP has analyzed the Locost front suspension thoroughly, and has drawings you can lift the coordinates from. His geometry page is here:

http://www.7builder.com/SuspensionGeometry/

I've done some work with the Locost design, too, with slightly different dimensions but similar results:

Rescued attachment LOCOST.jpg

cymtriks - 6/5/04 at 09:58 PM

I've already used Nastran to stress the chassis and improve it. My double Y braced chassis on the Photos section is the result. If you look

through my posts in the chassis section you can read the thoughts behind this and other builders comments.

The book chassis has between 1200 and 1400 ftlbs per degree of twist depending on the build. My chassis mods with a book style R tube engine bay brace

is around 2400. The double Y braced engine bay design has around 2700. FYI an Ultima is about 3300 and an Elise over 7000.

Regarding suspension Caterham have experimented with an all independant suspension design with roll centre heights of 65mm (rear) and 30mm (front).

The Deon version was 120mm and 60mm. The Elise has roll centres at 75mm (rear) and 30mm (front).

The camber change on the Elise was 0.31 degrees per inch at the front and 0.45 degrees per inch at the rear. This is very close to the recommendations

given by Costin (of Cosworth) of roughly 0.333 and 0.5 respectively for midengined race cars.

I'm still thinking about this issue but I've seen some figures for the Mazda MX5/Miata and the RX8 and these imply that camber change is

greater at the front on these cars. The MX5 suspension gains 0.9 degrees per inch at the front and 0.4 at the rear.

If anyone knows why the camber change is bigger at the front on the MX5 but bigger on the rear on the Elise I'd be interested to know.

pbura - 7/5/04 at 12:42 PM

Interesting discussion about rates of camber change on an engineering forum:

http://www.eng-tips.com/gpviewthread.cfm/qid/52395/pid/800/lev2/6/lev3/35

After reading it, I was impressed with the Locost's setup.

F1 cars have lower rates of camber change, but then again they are used on superior road surfaces and can stand harder springing, even without regard

to aerodynamics.

britishtrident - 7/5/04 at 02:39 PM

quote:

Originally posted by pbura

snip

F1 cars have lower rates of camber change, but then again they are used on superior road surfaces and can stand harder springing, even without regard

to aerodynamics.

I would put it even more strongly F1 one cars have NO suspension movement to speak of its all in the tyre sidewalls. It puzles me a bit when I see

F1 style equal length wishbones copied in lesser formula particularly those without wings or other aero down force such as Formula Ford. perhaps the

reason for this lies in the use of an effective rising rate suspension layout ensuring that the suspension rarely goes near full bump.

Almost 30 years back Ferrari built a test F1 mule with a composite beam axle at the front and a de Dion at the rear it was rated to have the potential

to give as good handling as the then current F1 but of course any developments in that line were killed stone dead by coming of the Ltus 78 & 79

and the sudden the need to generate underbody down force.

[Edited on 7/5/04 by britishtrident]

[Edited on 7/5/04 by britishtrident]

pbura - 7/5/04 at 06:43 PM

While I was out and about this morning, I was thinking about the F1 setup and realized that I was speaking some nutsack earlier.

With the lower rates of camber gain, F1 cars are actually better prepared to handle bump than roll. We know that their degree of bump is practically

non-existent, so they must roll even less.  This has got to be the result of very low Cg.

This has got to be the result of very low Cg.

I'm thinking that a racing Locost, with a very low ride height and lots of roll stifness, could also make do with less camber gain in roll than

'book', thereby gaining better traction in acceleration and braking.

This refers to the front suspension only as the book Locost has a solid rear axle, so no camber concerns at that end.

Been thinking about the comparison of the MX-5 to the Elise, also, and the difference in F/R camber gain must be due to weight distribution. The

middie Elise is rear-heavy (62/38) so needs better rear traction in cornering, while the 50/50 MX-5 can make better use of traction for

acceleration.

Edit: I didn't say nutsack! Chris!!! Crasser than b*ll*cks, IMO.

[Edited on 7/5/04 by pbura]

britishtrident - 7/5/04 at 07:05 PM

Re Comparing Elsie and MX5 you Pete is about the weight distribution also because of this the the roll couple distribution has to different, I

wonder also if available space for the the top wishbone link on the Elise might also be limited.

It might be worth finding out what static camber both cars are running.

Digging into memories of the original Elan out it had very little camber change on the rear because of the Macpherson/Chapman strut. The Front

wishbones were the the usual 2/3 ratio but couldn't have been much different anyway because of the large ammount of kpi built in to the Herald

based front suspension.

[Edited on 7/5/04 by britishtrident]

Digger Barnes - 8/5/04 at 09:22 AM

mmm all very interesting folks.

It gives me something to aim look into.

Yes Pete from reading the live rear is supposed to lighter than the IRS setup, but is this still true if I am using alloy uprights and hubs with bike

4 pot calipers and disks? (Not that this is the route I will be definitely taking).

Cheers Cymtricks I have had a look though your FE stuff very interesting, I have taken note of your mods.

British Trident and all very interesting the comparison between the different good handling motors, this sort of info is invaluable to help decide on

the final setup.

pbura - 9/5/04 at 02:10 PM

quote:

Originally posted by Digger Barnes

Yes Pete from reading the live rear is supposed to lighter than the IRS setup, but is this still true if I am using alloy uprights and hubs with bike

4 pot calipers and disks?

Gareth, I'm playing devil's advocate with myself as well

Pluses for the IRS for me are easier packaging of the bike shocks (though it's still a bit messy) and a better ride for a road car. Negatives

are a lower RC that's going to introduce more roll and compromised camber control

The Elise has tires made specially by Yokohama that can apparently tolerate a lot of camber, as the Elise uses -1.75 degrees static camber at the rear

(couldn't find anything for the front, but it must be large as well).

For us civilians without a red telephone to a tire company, we'd probably do best patterning an IRS Locost after the MX-5. I'm thinking

along the following lines:

Roll centers: 1.75" front, 3.5" rear (or higher if I can get it)

Camber gain: .75 deg/in. front, .45 rear

With the lower roll centers, I expect that front and rear ARBs will be needed. I would also anticipate poorer adhesion at the rear, so might fit

larger rear tires and definitely use a higher front-to-rear roll couple distribution.

With regard to roll couple, this page gives a good feel for the MX-5's front vs. rear springing:

http://members.aol.com/solomiata/swaybar.html

Pete

Peteff - 9/5/04 at 04:50 PM

Right on Syd. I built mine without knowing anything about all this technical stuff and now I'm worried where my roll centre is. I went all the

way to Stoneleigh and didn't find it. I've just read the other post and now I'm worried about my ackerman angles as well . Is that

like bizniss ackerman?

. Is that

like bizniss ackerman?

[Edited on 9/5/04 by Peteff]

britishtrident - 9/5/04 at 05:19 PM

Mazda seem to have bulit the Mx5 suspension with RCs not far off those used on the 60s Elan.

britishtrident - 9/5/04 at 05:28 PM

quote:

Originally posted by Syd Bridge

More talk about 'roll centres'.

Absolute bollocks!

When are you lot going to cotton on to the fact that the car rolls about the contact patch, and not the sodding 'roll centres', which have

absolutely no relevance whatsoever!!

Cheers,

Syd.

Reminds me of the guy who wrote to a motoring magazine saying they were slagging off the handling of Lada in a road test and his Lada handled

perfectly neutral it didn't oversteer or understeer..

Having spent a few years running Imps and Davrians on the track I became very much aware just how powerfull an effect roll centre height has.

As for Locost you decide the RC height early if it is anywhere near right ball park leave it alone and from then on tune the oversteer/understeer

balance with changes to spring rates at each end and/or anti-rollbars.

Wadders - 9/5/04 at 05:30 PM

Just pull your jumper up Pete, thats where i found mine (too much draught Murphys). Dunno about those ackerman angles though, they sound dead

painfull.

now I'm worried where my roll centre is. I went all the way to Stoneleigh and didn't find it.

pbura - 9/5/04 at 07:02 PM

quote:

Originally posted by Syd Bridge

Absolute bollocks!

Hey, how'd you do that?

bollocks (that's b o l l o c k s)

I'm so glad I read Sid's post before dropping 100 clams on Milliken. A couple of generations of automotive engineers across the whole world

are ... WRONG!

Well, pee on the Locost, then, I'm going to get myself a Lada, with some good tires.

And a big spoiler

Pete

P.S. to Peteff: The book design is fantastic. All this belly-button gazing is over building a non-book car, and hoping to get it to behave like a

book car. There, that made sense, didn't it? And it's fun in a twisted way.

britishtrident - 9/5/04 at 07:03 PM

The front suspension on a Imp has real SWING AXLE the camber change is constant irrespective of ride height under pure roll camber change is

ZERO, actually almost zero because in real life the RC lies between the suspension pivots which are about 3.5" apart.

With a car with Imp suspension lower the car and the front RC lowers by roughly twice the ammount of the rear RC resulting in a change from understeer

to oversteer.

This roll centre stuff isn't new , stage coach builders used to stop the passenger compartment on coaches rolling 200 years, by the start of

the 20 century Fred Lanchester was using it on cars flollowed 25 years later by Oley then Issigonnis and Chapman. In the 50s Grand Prix teams

such as Cooper and BRM used to build cars they could change the roll centre on to trim the handling until Chapman, Broadley Terry et al taught them

it was quicker and better to set the RCs at the design stage and use roll stiffness to trim the car.

What roll centres and more importantly the line joining them the "roll axis" are about is the fore aft distribution of weight transfer in

cornering.

Bob C - 9/5/04 at 09:05 PM

Syd says we can't use the term "roll Centre"

Ooops damn - just said it, er - roll centre that is

DOH said it again...

Actually I reckon it's a useful concept that those of us who don't make cars for a living can use (in the absense of anything else) to make

decisions about suspension geometry.

And this forum is a better place for folk like Pbura & Cymtriks & even BT(!) who are prepared to give their time to other builders.

Obviously you can make a car using much simpler "rules" & it would probably feel just the same to a donkey like me! Recent calculations

showed the Tiger rear roll centre moving several feet sideways (!) under roll - Is that right? What does it feel like?

It's my personal beleif that performance motors are associated with very stiff suspension because the only way the manufacturers could get the

standard cars to handle was to STOP THE SUSPENSION WORKING. Yet Chapman @ lotus was renowned for making softly sprung performance cars; I've seen

the old elise(?) (the early fibreglass monocoque one the diffs used to fall out of) at incredible angle of roll in competition, obviously competitive!

I'm aiming for soft springs in my 7 so I figure I need better location than owners with 275lb springs on.

Hey if it doesn't work out its only a few notes for another set of springs..

Meanwhile thanks to the guys who give out information, I guess we all have to put our own filter & credibility weighting on whatever we read.

It's also a duty on us all to point out dangerous errors & that also seems to be done courteously and efficiently hereabouts.

Plenty waffle there fellas anyone still awake??

Cheers

Bob

NS Dev - 9/5/04 at 09:22 PM

My turn to waffle!

My first disagreement with Syd! Roll centres do make a difference, and can be changed. Indeed the ingenious "Mumford link" rear suspension

even allows the rear roll centre of a live axle car to be adjusted pretty quickly. Can't be bothered to go on about it here, but needless to say,

I'd rather get my car built that worry for ages about the roll centres etc, it is a proven fact that most Caterhams and Westfields handle better

than my ability to drive them so I am not going to worry for too long!

Peteff - 9/5/04 at 11:01 PM

The best example of ackerman I could think of was the old Triumph Herald. Look at one of those on full lock and it looked like it was going to trip

over the inside wheel.

Digger Barnes - 10/5/04 at 12:02 AM

Can't sleep very knackered.

But it seems to have opened up a whole can of whoopass in this thread.

Yes about the roll center is to quote Milliken "the roll center establishes the force coupling point between the sprung and unsprung masses. When

a car enters corners, the centrifugal force at the center of gravity is reacted by the tires. The lateral force at the CG can be translated to the

roll center if the appropriate force and moment (about the roll center) are shown"

From this it would seem that everyone has a valid point.

I do remember something Einstein once said about things moving relative to the observer. The roll center principle is a convenient way of calculating

what the camber curves are for a given roll. Ok it does not take into account springing and weight transfer, jacking etc. But it is a good starting

point for finding a good geometry setup. The rest can come in the next stage.

Digger Barnes - 10/5/04 at 12:05 PM

quote:

Originally posted by Syd Bridge

I'll leave this thread with one thought for you. Wide, flat tyres need to be kept as stable as possible to maintain grip.

As you can see, your pet subject has not entered the discussion. This a plain exercise in geometry.

Keep the CoM as low as possible, weight distribution centred, configure your suspension to keep the tyres stable, and you can't go far wrong.

The books are not entirely irrelevant, but can put some very thick clouds around something that is quite simple and straightforward.

Yep it all got a bit out of hand didnt it as the original question was effectively asking what geometry change for a given roll etc is acceptable for

a track car, hence assuming that the springing will be set up correctly for the given geometry and weight distribution so that the max roll bump etc

in the design are not exceeded.

Yep the books may cloud the issue if you do not understand what they are saying. But it is a good place to get the math from if you can't be

bothered to derive it (as I did with the geometry to understand the relative movements possible).

Yes it is obvious that the idea is to keep the tyre contact patches as large as possible. Which with good basic geometry makes things a whole load

easier rather than eliminating suspension travel with extremely hard springs after it has been built with cr@p geometry.

As to being an armchair expert, mmm well everyone has to start somewhere and if you have no experience and are deviating from the book then learning

how things move relative to one another enhances the understanding of how the suspension works. I would assume it is a logical step to understand the

geometry before you understand how forces act upon it?

BTW I am writing software that is drag and drop to deal with all of these issues (I know there is software out there already available but I am an

applied physicist and by nature need to understand all the factors at play and how things are calculated to feel at ease, strange but true). Once

finished it will require very little knowledge of this whole issue to use, hopefully helping others who deviate from the book to come up with an

acceptable design only knowing a few things about the donor bits that they have sitting in front of them and then an hour or two or dragging things

about rather than months of learning.

The next stage for me is to incorporate all of the forces at play assuming a ridged chassis. This will give a better representation of how geometries

move for a given situation. Although it is almost impossible to allow for all the real world dynamic interactions in the model it should be possible

to get a good enough idea how the tyre contact patch varies in the worst case scenarios give or take several % for unaccounted for factors.

Then eventually when I have the car built (it has been started and parts are being made bit by bit) and it has been round the track a few times then

maybe I will be able to call myself experienced in real world suspension design rather than just in theory.

[Edited on 10/5/04 by Digger Barnes]

Digger Barnes - 10/5/04 at 03:18 PM

No offence taken.

It certanly has been an interesting deviation from the origonal post. As you say listening to what others have to say then doing some basic proofs (so

as not to take hear say as fact) takes your knowledge along in leaps at times when otherwise it may have been small steps.

Cheers

Gareth

pbura - 10/5/04 at 03:39 PM

Syd, you can liken us to sh*thouse lawyers, but these vaunted experts with their GPS sensors and captive programmers aren't helping US too much

I've been thinking about the nature of that line from the contact patch to the instant center of the wishbones. A force applied above the line

compresses the tire, and if below the line would provide lift. The action is very similar to dive and squat behavior in the longitudinal plane, and

each tire is really on its own.

So when a roll center is fixed laterally, it means what? That downward force is being relieved from the inboard wheel* at the same rate that

it's being applied to the outside wheel*? If my understanding is correct, then I can imagine that the 'feel' would be predictable and

reassuring to the driver. But maybe it's not what will get the car around the corner the fastest, which may be your point.

Shee-it, this stuff is complicated. Admittedly, the geometric roll center model may be outmoded with the automotive elite, but it's all that us

hoi polloi have for now

Gareth, I didn't know that you're loaded with some serious ammo, and I look forward to future developments

Hope you don't charge

too much!

Hope you don't charge

too much!

Pete "Willing to Learn" B.

*Edit: Whoops, meant "springs".

[Edited on 10/5/04 by pbura]

Digger Barnes - 10/5/04 at 04:35 PM

Pete watch this space it may take some time till I am happy with a final program (many months), but you should be getting a copy of the drap n drop

geometry stuff in a week or so.

As to geometrical lateral fixing of the roll centre in roll (I will only answer part of your question for now); if my understanding is correct it is

only possible to limit its movement with the geometry and not to absolutley fix it unless the geometry is set up as a paralellogram (which would be

cr@p) hence the fixing it at ground level at the center of the car (infinite IC's).

cymtriks - 16/5/04 at 08:51 PM

Ok, the car does roll about the tyre contact patches.... BUT The feel and dynamic behaviour of the suspension is greatly influenced by the roll centre

height and the camber gain in roll.

Just because all loads ultimately go through the contact patch doesn't mean that how the main mass of the car is controlled and moves relative to

those patches isn't important.

Too high a roll centre results in the suspension trying to fold under the car making high speed cornering feel, and sometimes be, very disconcerting

especiall when accompanied by large camber changes as on swing axles. This effect is called "jacking". This is why sports cars usually have

low roll centres. This increases the tendency to roll but this is countered by the stiffer springs and anti roll bars on sports cars. The result is a

firmer ride but secure and predictable handling with good feel.

Too low a roll centre increases the suspensions susceptability to road imperfections in feel and action. This is why even F1 cars rarely go below

below ground level with most curent designs being around 20mm (so I'm told). The fact that the front roll centres of both the original elise and

the revised all independent Caterham are at 30mm suggests that this might be the practical lower limit for road sports cars.

FYI the original elise used off the shelf tyres. The latest version uses special tyres. All my data relates to the original version.

jcduroc - 16/5/04 at 10:48 PM

quote:

Originally posted by cymtriks

Ok, the car does roll about the tyre contact patches....

A doubt suddenly assaults my thoughts: how does a rigid body roll about TWO different points (if each axle considered separately) or FOUR contact

patches?

Shouldn't it be around an axis?!

Joćo

crbrlfrost - 17/5/04 at 12:01 AM

It does roll about an axis, one that passes through the two roll centers. Thats why it is more involved than simply deciding on a static roll center

and calling it a day. Cheers!

crbrlfrost - 17/5/04 at 02:42 PM

Just a quick question, which books are you referring too? I'll grant you the most accrurate is looking at it from the newtonian physics point,

but to some extent, that is reinventing the wheel. Reiterating chassis-suspension interactions via forces can get downright confusing after a while

(done that) versus a geometric understanding (roll centers, axis, inclinations, etc). But point taken.

Bob C - 17/5/04 at 08:48 PM

the way i'd rationalised this......

the car doesn't rotate round it's tyre contact patches, but each wheel does.

"Roll centre" has bugger all to do with mr newton, everything to do with a network of links.

If you let the wheel rotate sideways round it's contact patch, the chassis will rotate around an imaginary point that I call its roll centre.

What is so offensive about this model?

bewildered of knutsford.

PS very few models used to predict real world behaviour are absolutely correct at unrealistic extremes - otherwise they become too complex to be

useful. Replace suspension units with solid links? - then it's not actually suspension any more is it!

As I've said before - Syd could well be right & it's all hot air & doesn't matter a damn, but at least it's given me a way

to calculate where my wishbones should pivot & how long they should be - so I feel a little bit more comfortable than if I'd just guessed

(which was my original intention!)

andkilde - 17/5/04 at 09:30 PM

ROTFL...

Poor Syd

OK, just to throw another uninformed opinion into the mix.

Syd, I gather that you're trying to expose "Roll Center Theory" for the convenient fiction that it is.

i.e. Someone, many moons ago, tried to come up with a simple explanation for the complex interaction between a vehicle and the road surface. From

this, the concept of roll centers at either end of a common roll axis came to be. A nice concept, one which has hard and fast rules and ways in which

to easily calculate (statically). But, it is flawed, as the geometric centers "float" about as a car actually rolls and to run through the

whole gamut of permutations and combinations actually requires some heavy duty math and computer power (starting to lose the simplicity factor) to

figure out the "whole picture". Also, tires (tyres?) have their own ideas of how to behave which isn't easily calculable.

Now, everyone's goal is to have loads of traction and "predictable" handling.

There is no arguement about what you need to achieve this -- keep the tires as close to square with the road as possible, point them in the correct

direction(s) and share the work (weight for simplicities sake) as equally amongst the four contact patches as possible. We'll call all this the

"Happy Tyre Place".

Now, let's look at what happens to a car in real life. Your car will flop about (a bit) from side to side and fore and aft as you accelerate,

turn and brake. While it's flopping about you want the tires to remain as close to the "Happy Tyre Place" as possible. To this end we

try to determine and control camber and pitching through "Suspension Geometry". Now, by this point, things are coming at us at a fast and

furious pace, we've got roll centers, anti-dive, uncle-squat, moments of inertia, et flipping cetera, ALL OF WHICH are mathematical fictions

(sometimes known as models) designed by smart people to try and explain complex things to the rest of us.

Truth is, keeping the weight (mass) low and as close to the center of the car as possible is good. Keeping your tyres upright while your car flops

about is good. Controlling the degree of flopping about is also good but, funnily enough, doesn't affect the handling much as long as you remain

near the "Happy Tyre Place". Too much (or non-standard) flopping about can affect your perception of the car's handling though.

Now to the part where trouble begins...

How do I design a good suspension?!?

Turns out our "convenient fiction" with roll centers low in front, slightly higher in rear, often (when combined with well distributed

weight) will provide good camber control in roll and predictable handling. That said, the roll centers are still a "fiction" and a

theoretical car with "perfect" roll centers can have poor camber control and handle very very badly if it happens that our models and

reality end up conflicting with one another. So, the most important thing is still the "Happy Tyre Place" and we have to be careful that we

end up building functional cars rather than disfunctional mathematical models.

Or, to paraphrase what I've seen written previously, bottom arms roughly parallel to ground, top arms, shorter, sloping down a bit towards center

of car. Drive it to see how it feels/works and muck about with it until it's right.

Just for laughs throw in kingpin angle intersects ground through centerline of tire (prevents tire being kicked offline by bumps) steering arms

configured for full Ackerman (helps with "turn-in" prevents scrubbing of inside wheel and some say let's the inner wheel do more

"work" ) and, make sure your inner tie rod arms proscribe the same arc as your suspension arms to avoid bump steer.

Sounds great, now let's all go do it

Cheers, Ted (who has had a bit of Uni Physics in his past but still sucks at billiards)

[Edited on 17/5/04 by andkilde]

ceebmoj - 17/5/04 at 09:37 PM

Not got much to add I started playing around with the idea of designing my one car over a year ago (how hard can it be I thought) and then I came on

sights like this and found that there where a lot of things that I did not know about and realised I would need to take in to account thanks to every

one who has taken there time to add to discussions like this even if you all disagree I think I have learnt a lot.

So 6 months or so ago I started working on a couple of simulations programs. A simple FEA i.e. for use by idiots like me and a suspension geometry

program also for idiots like me. Digger maybe we can swap some notes and mabby collaborate on this.

[Edited on 18/5/04 by ceebmoj]

MikeP - 17/5/04 at 10:36 PM

LOL, great fun.

Is it possible there's some confusion between weight transfer and chassis roll? Certainly Syd and Newton are correct, the roll center does not

have any affect on weight transfer to the outside tires - that value is constant. It doesn't change regardless of using no springs or solid

links, a high roll center/axis or a low one.

But Syd's solid link model doesn't break the roll center / roll axis theory. The roll axis and roll center affect only the amount of

chassis roll and the tire's "happy place"  as Ted says - for independent suspensions anyway. But they also affect the distribution

of the weight transfer between the front and rear tires.

as Ted says - for independent suspensions anyway. But they also affect the distribution

of the weight transfer between the front and rear tires.

I use this mental model - if I stiffen the rear (or shorten the roll couple), the softer front now compresses more than the rear in the turn. Just as

if the chassis was raised at the rear when stationary, the fronts get more weight and can generate more traction. The front gets tighter, the rear

loosens.

In the solid link case, the links prevent the weight transfer from changing front to rear, so the traction distribution remains constant too (not

counting braking or acceleration or bumps).

Syd's example triggers an interesting thought - his solid links are like converting the entire car to unsprung weight. Could stiffer springs be

like converting a higher proporation of the car to unsprung weight at that end of the car? And the front/rear weight distribution be modelled that

way?

cymtriks - 18/5/04 at 08:53 PM

As echoed by others the important point of my earlier post is this-

"Just because all loads ultimately go through the contact patch doesn't mean that how the main mass of the car is controlled and moves

relative to those patches isn't important."

The fact that cars work well with such a narrow range of possible geometry and suspension designs suggests that suspension and its geometry is

important.

Syd, we know that the loads are ultimately reacted through the contact patches and that consequently a car ultimately rolls about them. However the

main mass of the car is still suspended and the geometry of the suspension influences how the contacts move relative to everything else and so

suspension design is important.

Have your contacts got anything to add to suspension design other than rubbishing our approach? If a different way of looking at the problem indicates

a better design then we'd like to know more. I'm fairly open to alternative views as i've tried to think this through from a contact

patch point of view myself. So far you haven't given much of a clue as to what you are getting at.

jcduroc - 18/5/04 at 11:08 PM

quote:

Originally posted by cymtriks

As echoed by others the important point of my earlier post is this-

"Just because all loads ultimately go through the contact patch doesn't mean that how the main mass of the car is controlled and moves

relative to those patches isn't important."

The fact that cars work well with such a narrow range of possible geometry and suspension designs suggests that suspension and its geometry is

important.

Syd, we know that the loads are ultimately reacted through the contact patches and that consequently a car ultimately rolls about them. However the

main mass of the car is still suspended and the geometry of the suspension influences how the contacts move relative to everything else and so

suspension design is important.

Have your contacts got anything to add to suspension design other than rubbishing our approach? If a different way of looking at the problem indicates

a better design then we'd like to know more. I'm fairly open to alternative views as i've tried to think this through from a contact

patch point of view myself. So far you haven't given much of a clue as to what you are getting at.

Clap! Clap! Clap!

Suddenly, in the up till now silent theater, applauses were heard prizing the so much awaited "line"!...

Apart from apples that fall down on our heads, Syd, what do you have to tell us that can help everybody make better Locost's?

Longing for something really substancial...

Joćo

[Edited on 18/5/04 by jcduroc]

crbrlfrost - 19/5/04 at 01:23 AM

I'm in complete agreement that "roll center theory" isn't exactly an exact science, but rather a model. As such, it provides a

descent way to layout an sla suspension without running throughan impossible number of combinations. And, just a thought, that model was developed by

a group of scientists that were employed by the likes of GM to NASA. The fact that the model is often oversimplified for the sake of beginners

doesn't make the model obsolete. A vehicle is a dynamic body, and thus anytime we analyse it statically, it becomes a gross oversimplification.

But it is a solid basis. But since this thread seems to have become a pissing contest, I'm sure none of this will matter. Oh, by the way, I have

worked the physics for small formula cars, and I still vouch that the "roll center theory" comes close, albeit some aspects slightly over

emphasized. Cheers!

andkilde - 19/5/04 at 03:02 AM

quote:

Originally posted by Syd Bridge

Andekilde, if you have an education in physics, then your sarcastic remarks show that you wasted a lot of money to achieve little. I have a son in the

third year of his physics masters degree, and he can put the maths to this. So you must be able to?And you believe in antidive and anti squat!

He who laughs last, and all that...

He who laughs last, and all that...

[Edited on 18/5/04 by Syd Bridge]

Now Syd, play nice...

If you'll re-read my post carefully I'm (at least) half agreeing with you. All of the items I mentioned are mathematical models used by

folks to attempt to describe and control vehicle behaviour. Not once did I state or imply that the models were correct.

They are what they are though -- models are simplified predictors of complex interactions, and as such are doomed to fail miserably outside of a

tightly controlled range of situations.

Now, since you're Mr. Smartypants, why dontcha fill us peons in on the simple, derived from 1st principles method of designing the perfect

suspension with perfect camber control

I'll tell you why! Because it really isn't all that simple

But! We're not going to go up against Ferrari for the F1 title, we just want stable, predictable specials to play and tinker with. So, for our

purposes, cobbling together some simple ideas stolen primarily from what's worked in the past for other folk is as close to perfect as we're

likely to ever need.

And for those of us silly enough to ask, WHY? It is useful to start with available models and understand that they are fallible and need to be

thoroughly tested to ensure that our tires are correctly positioned throughout their range of motion.

Cheers, Ted

p.s. FWIW, on paper, I'm brilliant at billiards, it's only when I pick up a cue that it all goes pear shaped

This has got to be the result of very low Cg.

This has got to be the result of very low Cg.