suspension book

dblissett - 21/4/04 at 09:00 PM

i am having a nightmare trying to sort out my irs for my 442 i have used the avon dimentions and as the rear suspension rises the top of the wheels

move outwards i think this is possative camber and it should be the oposite

before i loose my temper and scrap the lot can anyone recomend a good book on suspension design or should i give up on irs and get a dedion tube from

gts

does this tube fit a +4 chassis

cheers a very pissed off dave

wicket - 21/4/04 at 09:06 PM

How to build & modify Sportscar & Kit car Suspension & Brakes; Des Hammill

Simple easy to understand diagrams & description, needs to be read a few times I think to fully understand though.

Mark Allanson - 21/4/04 at 09:08 PM

I have it as well, bloody good book, cheap on Amazon

dblissett - 21/4/04 at 09:10 PM

as you have both got the book which way did you decide to go with your back suspension irs live axel or dedion

cheers dave

wicket - 21/4/04 at 09:12 PM

Live axle, Cortina, in a Luego locost chassis.

Mark Allanson - 21/4/04 at 09:15 PM

Live axle, capri in a book chassis

I will start modifying after the SVA, particularly trailing arm lengths and angles

pbura - 21/4/04 at 10:29 PM

Do you have any way to move your upper chassis pivots down? If you can, that would be the way to get a more satisfactory camber curve.

Here's a free suspension program that will allow you to see what it takes to get camber behavior similar to your front. If you can achieve that,

and a roll center that's (1) slightly higher than the front RC, and (2) stays fixed laterally in roll, you're home free.

Suspen

You might also need either longer upper wishbones (or shorter lowers) if you change these pivot locations.

Got a picture of your rear chassis?

Pete

jcduroc - 21/4/04 at 11:20 PM

quote:

Originally posted by dblissett

i am having a nightmare trying to sort out my irs for my 442 i have used the avon dimentions and as the rear suspension rises the top of the wheels

move outwards i think this is possative camber and it should be the oposite ...

Dave

I just found out the same when drawing an Avon-dimentions based IRS; have a look at this thread.

http://www.locostbuilders.co.uk/viewthread.php?tid=12252&page=1#pid102651

Use the "suspen" prog that Pete recomends.

I'm designing entirely my rear suspension based on a 1.6 Sierra diff + driveshafts.

How much will your rear track be?

Joćo

type 907 - 21/4/04 at 11:26 PM

Hi All,

I'v had a go at making my own IRS.

My top wishbone is about two thirds the length of the bottom wishbone. They start off horizontal, and as they rise the top effectively shortens more

than the bottom one thus creating negative camber on compression.

I haven't driven it yet, but it looks right.

Paul G

jcduroc - 21/4/04 at 11:47 PM

Try these:

Top wishbone

Chassis mounting from CL: 305 mm

-----"---------"------ from ground: 300 mm

Length: 295.5

Bottom wishbone

Chassis mounting from CL: 178 mm

-----"---------"------ from ground: 140 mm

Length: 407

Upright

CL height from ground: 269.3 (tyre rolling radius)

Top mounting from chassis CL: 585 mm

-----"---------"------ from ground: 594.3mm

Bottom mounting from chassis CL: 585mm

-----"---------"------ from ground: 144.3mm

Track is 1470 mm

Starting camber is 0ŗ (later to change to -0.5ŗ/-1ŗ according to tyres)

Roll center height: 108 mm (4 in. 1/4).

Pls, feed back the results and your opinion.

Cheers

Joćo

britishtrident - 22/4/04 at 06:30 AM

I don't know the avon suspension but if the top wishbone is about 2/3 the length of the lower one it is i the right ball park.

The inner pivots for the top and bottom rear wishbones need moved -- most likely the lower one will need to be raised so the lower pivot 0.5"

higher at the inner end than the outer and the upper lowered by perhaps 1".

My fvourite suspension book is "How To make Your Car

Handle" author Fred Phun Publisher HP Books ISBN 0-912656-46-8

[Edited on 22/4/04 by britishtrident]

Bob C - 22/4/04 at 10:03 AM

To get camber control right, your swing axle length (where lines through wishbone pivots converge) needs to be on the "car" side of the

wheel - i.e. the vertical separation of the chassis pivots should be less than the vertical separation of the upright pivots.

All the above applies - try to get an old dos program called "suspen.exe" to locate your roll centre properly if you can be bothered. U2U me

if you want it posting to you.

cheers

Bob C

pbura - 22/4/04 at 11:29 AM

quote:

Originally posted by jcduroc

Try these:

[snip]

Upright

CL height from ground: 269.3 (tyre rolling radius)

Top mounting from chassis CL: 585 mm

-----"---------"------ from ground: 594.3mm

[snip]

Pls, feed back the results and your opinion.

Was taking a peek, but outboard top pivot height of 594.3mm appears to be incorrect (taller than the wheel). What's the right measurement?

Your chassis appears to be quite low! Is it for racing?

Pete

jcduroc - 22/4/04 at 01:28 PM

quote:

Originally posted by pbura

quote:

Originally posted by jcduroc

Try these:

[snip]

Upright

CL height from ground: 269.3 (tyre rolling radius)

Top mounting from chassis CL: 585 mm

-----"---------"------ from ground: 594.3mm

[snip]

Was taking a peek, but outboard top pivot height of 594.3mm appears to be incorrect (taller than the wheel). What's the right measurement?

Your chassis appears to be quite low! Is it for racing?

Pete

Sorry all.

It's 394.3 not 594.3 (typing error).

No Pete it's for fun driving

Ground clearance is to be 115 mm at the front axle plane and 120 mm at the rear (very slight raking)

pbura - 22/4/04 at 02:45 PM

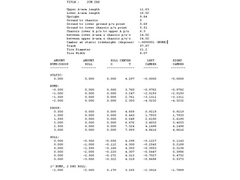

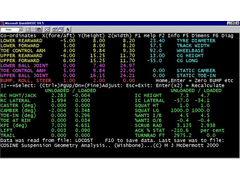

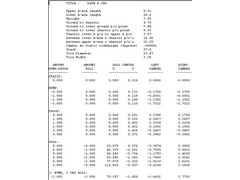

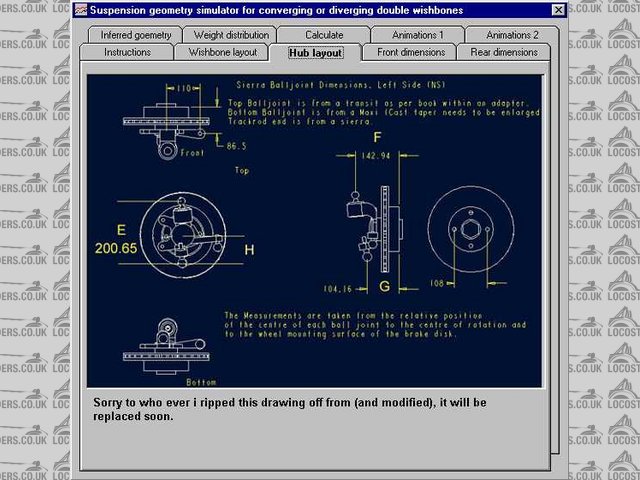

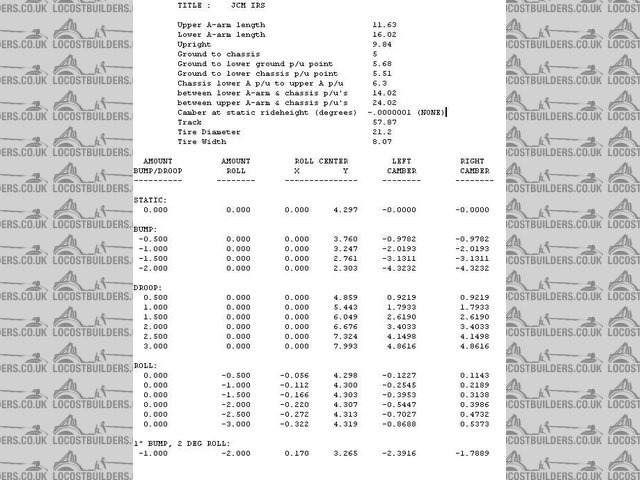

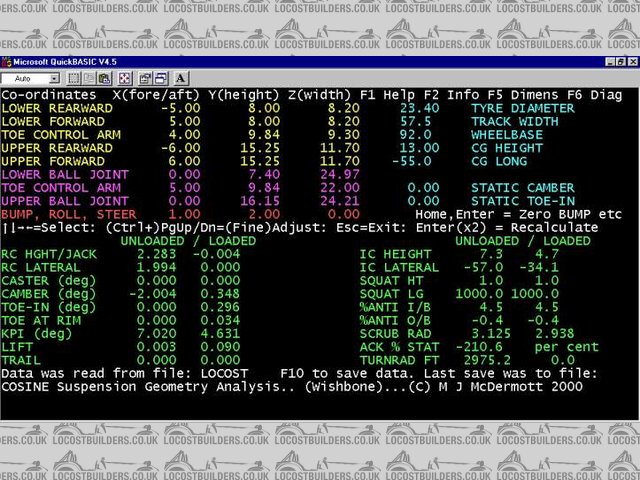

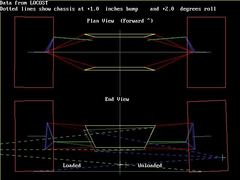

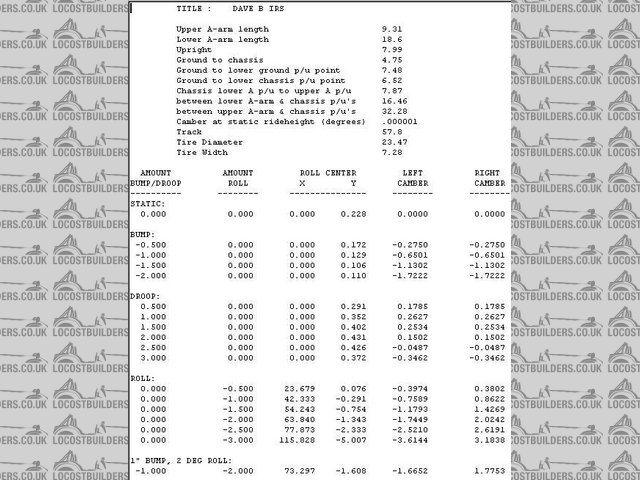

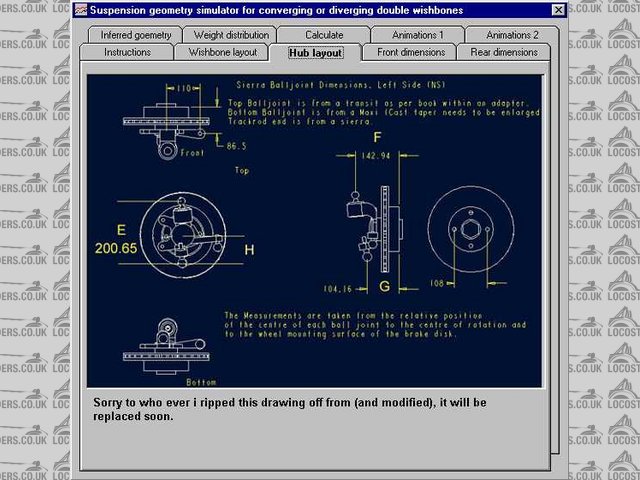

For everybody's info, below is the kind of data you get from Suspen.exe; I added some sub-captions to explain the movements.

Joćo,

Here's your data in Suspen. Sorry about the units of measure, but it was the only way. Camber change looks excessive, but if you raise the

upper inboard pivot along the same tube (if possible), you will fix this, and retain the very fine RC behavior, as you've found the Magic Angle

Please feel free to U2U or e-mail if you'd like to talk about alternatives.

ATB,

Pete

Rescued attachment JCMIRS.jpg

jcduroc - 22/4/04 at 03:23 PM

Pete

I just converted the inches to mm.

Before going into a deep analysis of the figures pls tell me:

* between lower A-arm & chassis p/u's (pivot mountings?) 14.02 (356.11 mm); where does it come from?

* between upper A-arm & chassis p/u's (pivot mountings?) 24.02 (610.11 mm); where does it come from?

Cheers

Joćo

pbura - 22/4/04 at 04:19 PM

quote:

Originally posted by jcduroc

Pete

I just converted the inches to mm.

Before going into a deep analysis of the figures pls tell me:

* between lower A-arm & chassis p/u's (pivot mountings?) 14.02 (356.11 mm); where does it come from?

* between upper A-arm & chassis p/u's (pivot mountings?) 24.02 (610.11 mm); where does it come from?

Cheers

Joćo

Those are the chassis mounting from CL figures, multiplied by 2.

P.

Digger Barnes - 22/4/04 at 05:35 PM

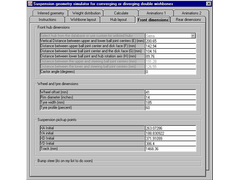

Hi I know I am bit late to this thread, but I am in the stage of designing my IRS at the moment.

I'll give you a bit of background to what I have been doing.

I felt that I needed to understand a bit more about suspension geometry and the like (I want to race the car and want it handle as well as is possible

having no previous experience apart from F#~+][g it up when I was a kid by lowering cars and changing wheels without thinking about the handling

implications). Anyway I digress so I have tried to read as much as I can about it and then write my own software to give me an idea about what is

going on.

So if you are interested I am just finishing (by the end of the weekend) the first verified (by me) draft. It is a windows program that I have

developed that I hope is easy to use. The dimensions it requires to simulate camber changes are the upright dimensions, wheel tyre dimensions, track

and the points in space of wishbone pickups.

The output gives you

Camber change in:

Bump or droop

Roll (roll center is calculated iteratively across the roll not just taken as the initial roll center of the car)

Bump and droop at the point of roll

Bump and droop during roll.

The output is currently to a csv file that can be read in note pad or excel (animations soon).

If you would like a copy u2u me and I will send one out.

Bob C - 23/4/04 at 06:11 PM

Chaps, I just looked back over this thread & realise my comments about suspen.exe could be construed as my thinking it was not much good.

That's not what I meant - it just came out wrong - the program itself is simple to use and enables you to nail your roll centres exactly where

you want 'em. And as Pbura said in an email to me, it's got to be a major factor in having a car feel nice to drive - what else is there?

(rhetorical question......). Previously I was just going to use the simple rules outlined by others - I'm glad I took the trouble (with a lot of

help from Pete) to do it properly. My initial rear suspension roll centre moved 3" sideways with 3 degrees of roll! Now it stays put. Cheers

Pete!

Bob C

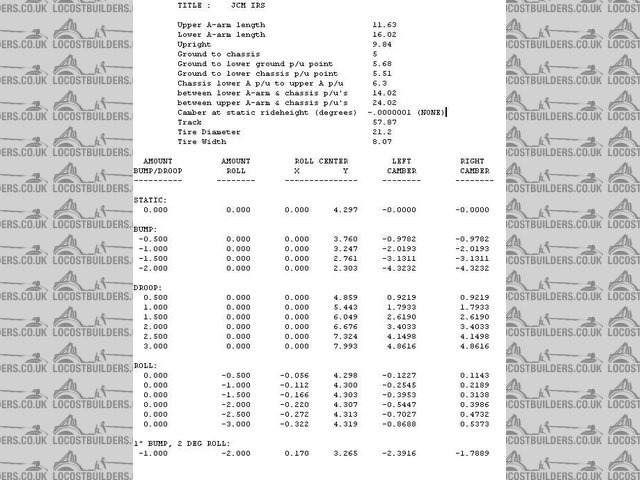

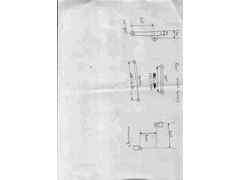

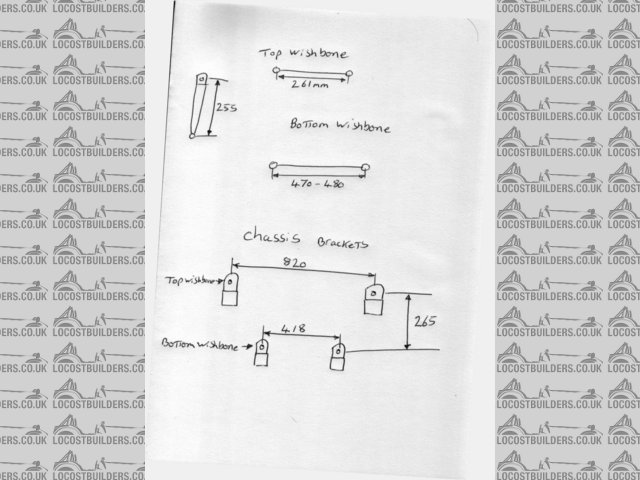

dblissett - 23/4/04 at 08:45 PM

here is a very rough sketch of my rear whisbones and moutings it looks like my top wish bones are to short being only 230mm long or should i add 35mm

to get their true length

thanks for everybodys help as i am calming down i wont be scraping the locost just yet

cheers dave

Rescued attachment whisbonesrear.jpg

Digger Barnes - 24/4/04 at 10:36 AM

Bob it is also my understanding that it is important to try and fix the roll center.

But I do believe (pure speculation as I have not done the calcs to see if it is achievable yet) that it would be advantageous to move the roll center

to the outer wheel in a corner in terms of handling, but I don't know how this would make the car feel.

So a few questions for the experts out there

So does anyone have experience of this to share?

Is it really possible to fix the roll center when different bumps and droops are added into the equation for different wheels?

p.s. my program also outputs the roll center position during roll.

jcduroc - 24/4/04 at 01:31 PM

quote:

Originally posted by Digger Barnes

Bob it is also my understanding that it is important to try and fix the roll center.

But I do believe (pure speculation as I have not done the calcs to see if it is achievable yet) that it would be advantageous to move the roll center

to the outer wheel in a corner in terms of handling, but I don't know how this would make the car feel.

So a few questions for the experts out there

So does anyone have experience of this to share?

Is it really possible to fix the roll center when different bumps and droops are added into the equation for different wheels?

p.s. my program also outputs the roll center position during roll.

I suppose that by "fixing the RC" you mean laterally.

In roll the outside wheel goes into bump the inside one in droop so the IC's will move (normally) in opposite directions.

RC will move both vertically (RC height)and horizontally (RC offset). It's almost impossible to keep 0 offset but it may br limited within

reasonable figures (<= 5 mm).

Joćo

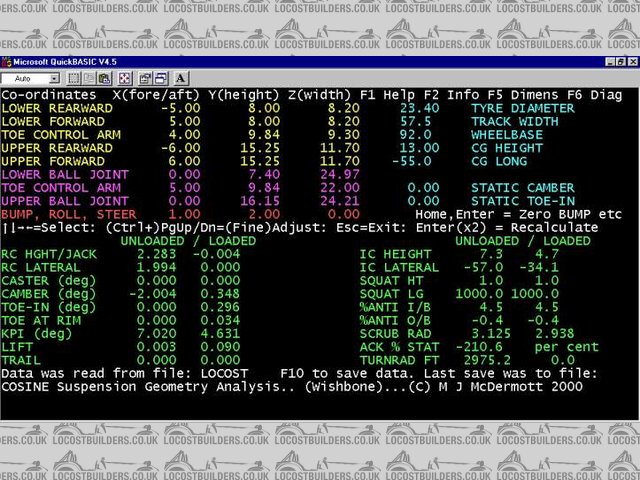

pbura - 24/4/04 at 02:28 PM

Bob C, thanks for the good report! I think that whenever anyone gets way off the book (and IRS certainly qualifies), they'd do well to

understand their suspension geometry. Like you guys, I've been reading up because I don't want to screw the pooch.

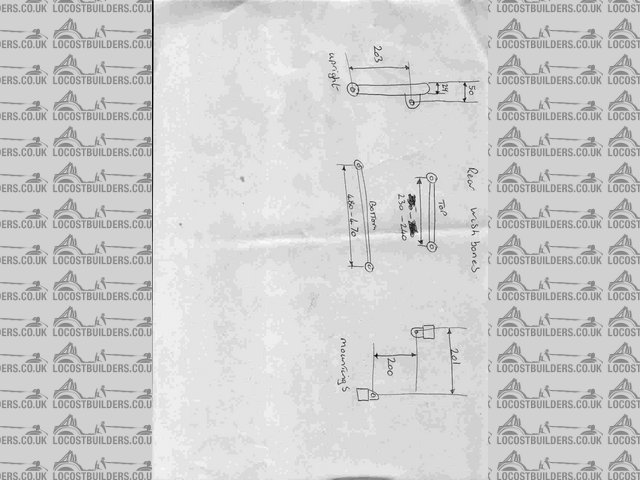

Another free suspension design tool that I like is the Wishbone program from Race Tech magazine, available on their downloads page. You need to

register to get it, and you'll also need Microsoft QuickBasic to run it:

https://www.racetechmag.com

What I like about Wishbone is that you can set the chassis in a particular attitude, like 2" bump or 2 degrees roll or some combination, then

twiddle suspension pivots until you get results that look good to you. You can then alter the chassis position and tweak some more. I flip back and

forth between 2" bump and 2 degrees roll to try to strike an effective compromise. I'll also test at 1" bump, 2 degrees roll (favored

by Staniforth for his string computer) because it's a very representative condition in cornering.

After doing the design in Wishbone, you can enter the settings into Suspen and move the suspension through its paces, to get a better sense of

what's happening in a dynamic sense. Suspen can do the whole job, but IMO it's a bit awkward for watching your camber change while

you're tweaking a pivot height, for example.

The only thing I DON'T like about Wishbone is that you're forced to deal with bump steer, which is a PITA during this design stage, though

it's a nice tool to have eventually.

I'm looking forward to checking out Digger Barnes' proggie, too.

Another thing I've done in the way of suspension design is to solve it graphically. The method I used was based on the classical "three

position analysis" method for solving four-bar mechanical linkages. I have a

page on my website about this. Sorry it's a bit hard to follow,

but the CAD program I used was not amenable to creating images for the web, or editing text. What I like about the graphical method is the degree of

control it gives you over the process, more like shooting fish in a barrel rather than jus' fishin'

Re: Fixed Roll Centers

Two writers I admire, Carroll Smith and Allan Staniforth, go on and on about the desirability of the fixed roll center. It appears to be a handling,

or 'feel' issue, rather than being essential to a car's actual ability to go around corners. The book Locost has a well-fixed front

roll center (and rear, with the solid axle), and I wonder if this isn't a big reason that people find the Locost's handling to be so

incredible, like it's riding on rails. Again, I think the off-book builder would do well to emulate the book geometry as closely as possible,

unless he really knows his stuff about suspension design (I don't). The book Locost RC moves a couple of inches towards the unloaded side in

roll, BTW.

Re: IRS Considerations

I've been fooling around with jcduroc's suspension coordinates, and so far I've learned that if you want a highish RC with IRS, the

layout will more closely resemble that described by type 907 and britishtrident, than what I stated in my first post on this thread. The top bone

will be close to parallel, and the bottom will point upwards somewhat from wheel to chassis. I may be wrong, but with this arrangement it seems

difficult to get really good camber curves in both bump and roll when the RC is much higher than about 3-4". One advantage of a solid axle or de

Dion car is the higher rear RC, which limits weight transfer in roll and maximizes the rear tires ability to provide traction for accelerating, IMO.

The conclusion I'm drawing is that a rear anti-roll bar is practically necessary with IRS.

Sorry about the long post!

Pete

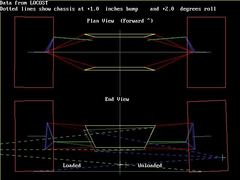

Below is my interpretation of the book Locost front suspension in Wishbone:

Rescued attachment Wishbone.jpg

pbura - 24/4/04 at 02:41 PM

Here's the related diagram:

Rescued attachment locost2.jpg

dblissett - 24/4/04 at 07:48 PM

i have to hold my hands up and say most of what is being said is way above my knowledge of suspension

with that in mind i think it might be better to admit my limitations and buy a dedion tube from gts

the last thing i want is to spend two years building a car that wont drive properly and i wont be happy with

it seemed like a good idea at the time

thanks every body dave

[Edited on 24/4/04 by dblissett]

pbura - 24/4/04 at 08:28 PM

The de Dion's awfully nice, and frankly that's how I'd go if I weren't doing inboard shocks. IRS is good, too, especially if

you've got your chassis built already and all you need is to sort the wishbones.

How far along are you?

Pete

Digger Barnes - 24/4/04 at 11:04 PM

quote:

Originally posted by dblissett

i have to hold my hands up and say most of what is being said is way above my knowledge of suspension

with that in mind i think it might be better to admit my limitations and buy a dedion tube from gts

the last thing i want is to spend two years building a car that wont drive properly and i wont be happy with

it seemed like a good idea at the time

thanks every body dave

[Edited on 24/4/04 by dblissett]

Dave it was way over my head about one month ago, but with a bit of reading you will start to understand how it all works well enough to use one of

the tools available to play with loads of different designs and by trial and error you get to a good design in a day or two.

Well thats what I am hoping once I know a bit more about what I want the camber to do in bump and roll in a track situation.

Good luck with what ever route you decide on

WIMMERA - 25/4/04 at 05:54 AM

The late Arthur Mallocks comment on roll centre movement in relation to chassis movement allways brings a smile to my face, he said, when describing

the nine different systems they had used up to that point, " if you use a chassis mounted Watts linkage it can't move because it's got

a bolt through it"

Bob C - 25/4/04 at 01:01 PM

Love the quote from Mallock!

The problem with IRS isn't the suspension geometry - the fact is all the wheel loads feed to places that just aren't there on the tried

& tested book design. A problem neatly side-stepped by the dedion solution!

Cheers

Bob C

WIMMERA - 26/4/04 at 01:25 PM

It's going to be interesting to experience the difference, I have a book version finished which is a great drive and a new car under way which

has inboard front suspension and IRS rear, the front also features zero scrub radius I'm treating it as an R&D exercise, I enjoy the build as

much as the driving, the new car is very adjustable, front and rear

dblissett - 26/4/04 at 07:39 PM

with the kind help from pbura i am going to try and sort my irs out

i will keep you all posted as to if i win or loose

only rons book said it was easy

cheers dave

[Edited on 26/4/04 by dblissett]

Northy - 26/4/04 at 08:24 PM

Dave,

Is your IRS an exact copy of the Avon? Does this mean the Avon is shite aswell?

I'd be very interested to hear how you solve it. Guess thats another Winter upgrade to add to the list

Cheers

dblissett - 26/4/04 at 08:39 PM

hello northy

no its not all the same the bottom wishbones dimentions are the same

the supports for top and bottom wishbones are in the same place but my top wishbones are shorter than the avon ones they conect in almost the same

place as the shocks there was a thread on the standard avon irs that thought the camber went posative as the suspension rose

search for a guy from portugal i think his name is juao or jcdoc he posted the comments on it but i have come to the conclusion that it must be a lot

better than any standard production box that we all drive day to day.

cheers dave

Northy - 26/4/04 at 08:49 PM

Cheers Dave,

I'll have a look, seem to remember seeing it now.

Has anyone modeled the std Avon rear suspension in one of these packages? Don't think I'll be able to manage it

Cheers

dblissett - 26/4/04 at 08:52 PM

when i have learnt how to put mine through i will put the standard avon through

this might take me a couple of months to learn though

cheers dave

Northy - 26/4/04 at 08:55 PM

Cheers Dave,

I'm not changing it now, perhaps next winter........

Cheers

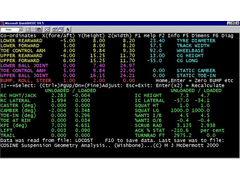

pbura - 26/4/04 at 09:17 PM

It's really not hard to do; I'll post the results for everybody to see, so you can try it on your own. Probably won't be until

Wednesday morning, though, because I have some rush work to do.

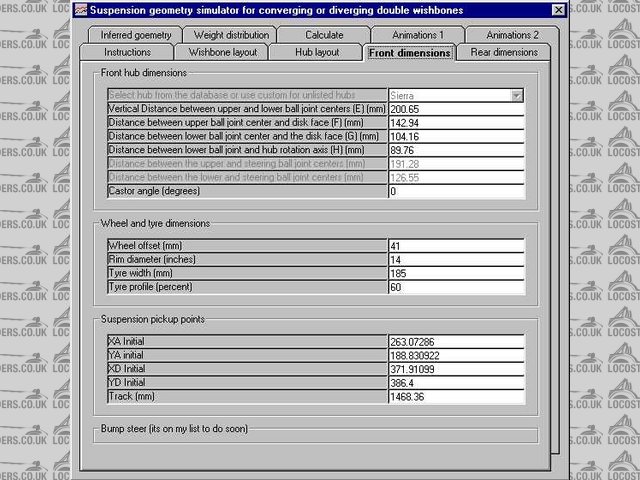

I'd be glad to play around with the Tiger setup, too, front and rear. The dimensions needed are the locations of ball joints and chassis pivots,

plus tire diameter (rolling) and track. Steering data is optional. You can see the data screen on page 3 of this thread.

Pete

Northy - 26/4/04 at 09:19 PM

Cheers,

Wonder if my book will fall on the scanner tommorrow........

jcduroc - 26/4/04 at 09:55 PM

quote:

Originally posted by dblissett

there was a thread on the standard avon irs that thought the camber went positive as the suspension rose

search for a guy from portugal i think his name is juao or jcdoc he posted the comments on it but i have come to the conclusion that it must be a lot

better than any standard production box that we all drive day to day.

cheers dave

Hi Dave

My forenames are "Joćo Carlos" and my ID is "jcduroc" and yes, I'm from Portugal.

quote:

Originally posted by dblissett

hello northy

no its not all the same the bottom wishbones dimentions are the same

the supports for top and bottom wishbones are in the same place but my top wishbones are shorter than the avon ones they conect in almost the same

place as the shocks ...

Doing that the only thing you'll achieve is to get static negative camber but in bump you'll gain positive camber all the same.

quote:

Originally posted by dblissett

... but i have come to the conclusion that it must be a lot better than any standard production box that we all drive day to day.

cheers dave

May be so ... may be not.

I cannot state positively on the Avon as I've never seen and/or driven one but conceptually (if it is built with Dudley's book dimensions)

it's a big "merde".

You should seriously consider (at least) lowering your rear upper wishbones' attachement points; wait for someone else's solution (IMHO).

HTH

Joćo

[Edited on 26/4/04 by jcduroc]

britishtrident - 27/4/04 at 07:19 AM

From study of photos in mags of the Avon front end I doubts about the position of the steering rack also --- it seems quite a a lot a head of the

trackrod ends and so must give a lot of toe-in in corners.

dblissett - 27/4/04 at 12:59 PM

hello joao

i was trying not to slag off the avon as some people have bought one as a built chassis and i dont want to make them unhappy with there choice

hello pete

i will email you the tiger dimensions

i have started to play with the program should all the dimentions be imperial

and i now have even less time due to the birth of my second daughter last night.

eve weighing in at 9lb 12 oz ouch

thanks dave

jcduroc - 27/4/04 at 01:35 PM

quote:

Originally posted by dblissett

hello joao

i was trying not to slag off the avon as some people have bought one as a built chassis and i dont want to make them unhappy with there choice

Dave

Better tell the truth beforehand than seeing our mates unhappy afterwards (I guess).

quote:

Originally posted by dblissett

... now have even less time due to the birth of my second daughter last night.

eve weighing in at 9lb 12 oz ouch

thanks dave

Don't know wahat that weight is but if Eve is crying full-lungs and sucking her mother's milk it is wonderful. Long life and happiness to

Eve and her parents.

Cheers

Joćo

P.S.: Father of two girls, grand-father of three girls and recently widow.

pbura - 27/4/04 at 03:56 PM

Dave,

Sent you an e-mail to confirm some measurements. When I hear back from you, then I'll post the originals and a suggested alternative, and

everybody can take some potshots

It would also help to know what your front end looks like. I know you have a +442, but would like to know also if you have book wishbones in book

locations, and what your front ride height will be. The reason I ask is that it's best to have your rear RC somewhat higher than the front, for

better turn-in. Also, I'd like to try matching the front and rear camber curves as best I can.

If the other thread about the Tiger wishbones pointing up toward the chassis is correct, probably the reason Tiger did it is to raise the RC so they

wouldn't have to have an anti-roll bar in back, IMO.

Congratulations on Eve's safe arrival, and may all of you have a happy life together

Pete

P.S. to Joćo: I'm a widower, too, and raised four children on my own for 7 years until remarrying almost two years ago now. I'm very sorry

for your loss.

jcduroc - 27/4/04 at 04:19 PM

quote:

Originally posted by pbura

P.S. to Joćo: I'm a widower, too, and raised four children on my own for 7 years until remarrying almost two years ago now. I'm very sorry

for your loss.

Thank you for your sympathy, Pete.

So you know how hard it is!...

Cheers

Joćo

Northy - 27/4/04 at 05:26 PM

Pete,

Have you got the dimensions for the std Avon rear suspension?

Would you be willing to do the front also at some point?  No rush though

No rush though

pbura - 27/4/04 at 08:17 PM

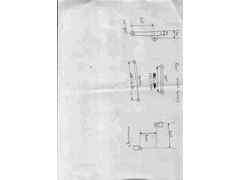

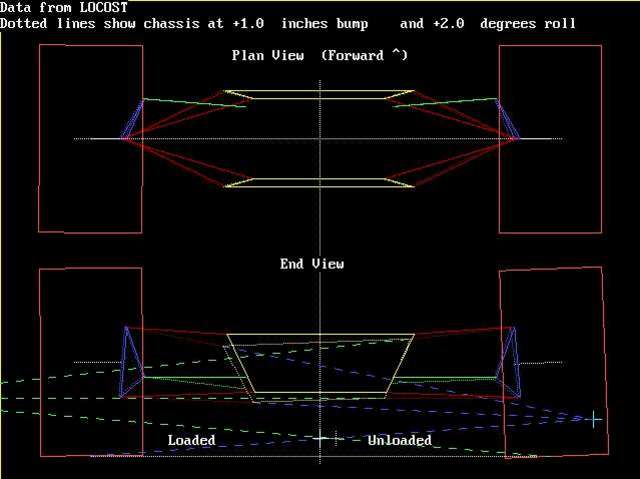

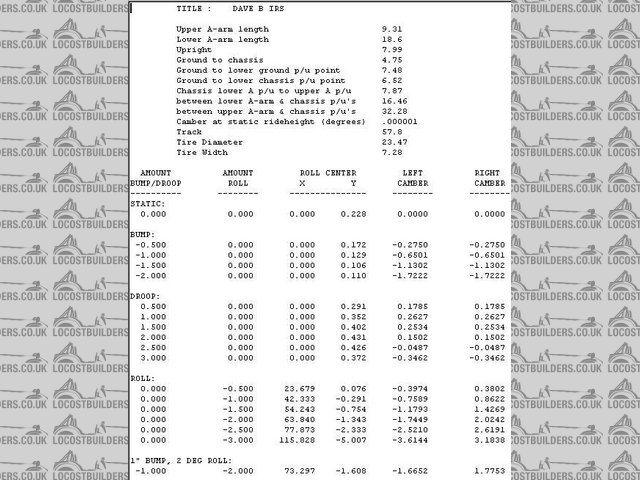

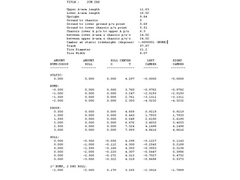

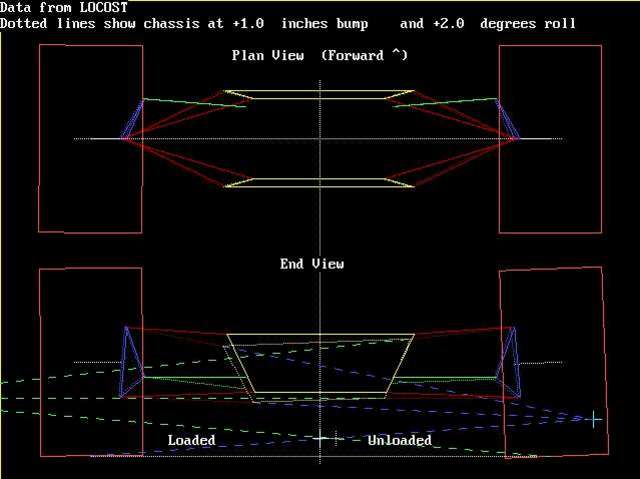

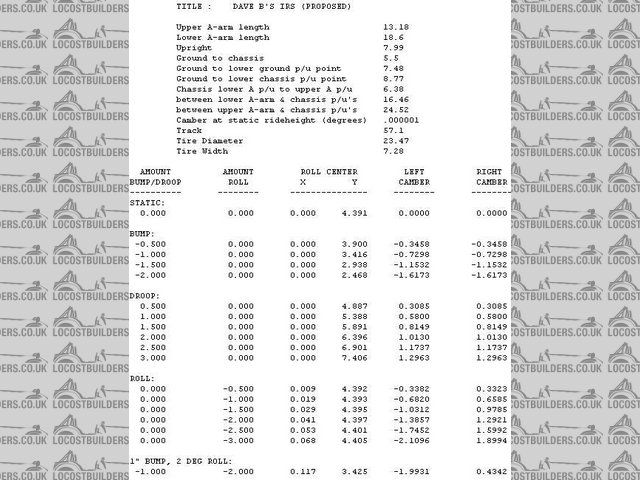

Well, I took a shot at Dave's suspension geometry, had a lot of fun, and got more behind with earning my daily bread

Here's the old data in Suspen:

Rescued attachment DLBIRS.jpg

pbura - 27/4/04 at 08:21 PM

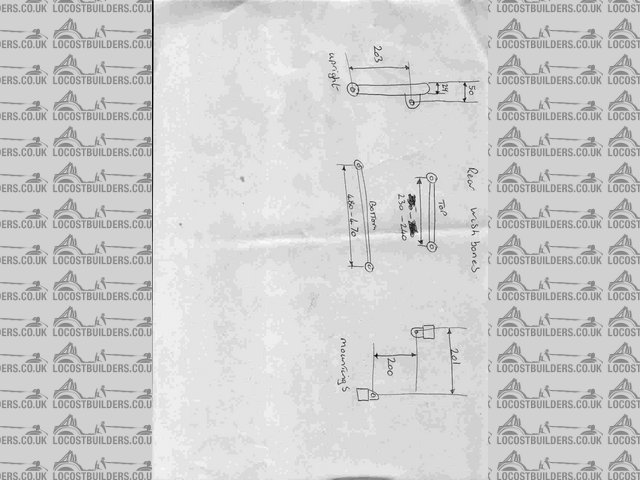

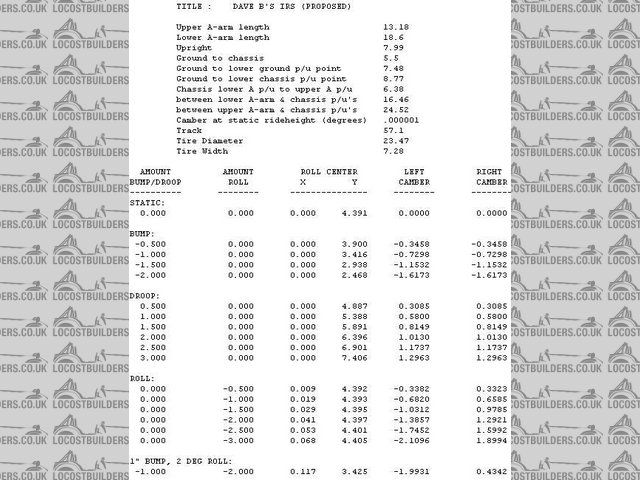

And the proposal, which was formulated to minimize extra work for him. Bottom wishbones are the same with a higher mounting, and the upper are longer

and mount further inboard, but at the same chassis tube height:

Rescued attachment DLBIRSREV.jpg

pbura - 27/4/04 at 08:42 PM

The change in the ride height from 4.75" to 5.5" helped raise the RC and to put the upper wishbone in a better position for bump and roll.

For a lower ride height, I'd go with a shorter tire/wheel combination (this one is 185/65-14).

The most serious change was raising the lower chassis pivot 1.5" in the same lateral location, and I hope this is possible just by making a

Big-Ass Bracket without any other modifications. Comments are welcome on this, and on anything else.

Pete

pbura - 27/4/04 at 09:07 PM

quote:

Originally posted by Northy

Pete,

Have you got the dimensions for the std Avon rear suspension?

Would you be willing to do the front also at some point?  No rush though

No rush though

No, I don't have them, but I'd be glad to help anyone that wants to analyze them.

By the way, I'm not representing myself as any kind of expert in these matters. One reason I've posted the screens from these programs is

to show people how they work, and to encourage them to do the same themselves.

Generally speaking, The R/C car guys have got us Locosters buried with regard to vehicle dynamics

Pete

Northy - 27/4/04 at 09:18 PM

quote:

Originally posted by pbura

No, I don't have them, but I'd be glad to help anyone that wants to analyze them.

By the way, I'm not representing myself as any kind of expert in these matters. One reason I've posted the screens from these programs is

to show people how they work, and to encourage them to do the same themselves.

Generally speaking, The R/C car guys have got us Locosters buried with regard to vehicle dynamics

Pete

Cheers Pete,

Which program should I start off with as a beginner? Do you just plug numbers in?

I'm an RC guy

Cheers

pbura - 27/4/04 at 09:52 PM

quote:

Originally posted by Northy Which program should I start off with as a beginner? Do you just plug numbers in?

I'm an RC guy

I use both Wishbone and Suspen. Wishbone is easier for setting up the problem and for adjusting pivot locations to improve camber, or whatever, in a

given chassis position. It sort of bites for dynamic modeling, though, which is where Suspen comes in. In Suspen, you just punch arrow buttons and

the chassis bumps and rolls as you please.

This routine works well for adjusting an existing design, but for a from-scratch design I'd rather draw it (like the example on my website).

A hybrid technique, like sketching the chassis to set the uprights, track, ride height, roll center height, swing axle length, and inboard lower pivot

location, then 'fishing' with Wishbone for the upper pivot, would work pretty well, too.

Digger Barnes has been working on a spreadsheet, too, and he says he'll be done with it soon. That'll be interesting to see.

These methods I'm using are low-rent, by the way. There's a program called SusProg3D that will determine pivot locations by reiterative

testing, probably the way to go for most people.

Pete

P.S. You RC guys are outrageous; best automotive tech info on the web!

[Edited on 27/4/04 by pbura]

Northy - 27/4/04 at 10:00 PM

quote:

Originally posted by pbura

I use both Wishbone and Suspen. Wishbone is easier to set up the problem and to adjust pivot locations to try to improve camber or whatever in a

given chassis position. It sort of bites for dynamic modeling, though, which is where the Suspen comes in. In Suspen, you just punch arrow buttons

and the chassis bumps and rolls as you please.

This routine works well for adjusting an existing design, but for a from-scratch design I'd rather draw it (like the example on my website).

A hybrid technique, like sketching the chassis to set the uprights, track, ride height, roll center height, swing axle length, and inboard lower pivot

location, then 'fishing' with Wishbone for the upper pivot, would work pretty well, too.

Digger Barnes has been working on a spreadsheet, too, and he says he'll be done with it soon. That'll be interesting to see.

These methods I'm using are low-rent, by the way. There's a program called SusProg3D that will determine pivot locations by reiterative

testing, probably the way to go for most people.

Pete

P.S. You RC guys are outrageous; best automotive tech info on the web!

Cheers Pete,

I'm in no rush, I'm not taking the bloody thing apart again now. Will be a winter upgrade I think

It amazes me just how adjustable RC cars are these days, and how responsive they are to the smallest change. But its a littl off putting when racing,

I often just leave it as I fear making it worse!  New tyres solve most problems!

New tyres solve most problems!

Cheers

Digger Barnes - 28/4/04 at 08:14 AM

quote:

Originally posted by pbura

Digger Barnes has been working on a spreadsheet, too, and he says he'll be done with it soon. That'll be interesting to see.

Yep finished the spreadsheet yesterday (quick and dirty way to see the output for now, real animations will be built into the program eventually) that

will animate the data output from my program. The program I am developing will hopefully be built along with my car build and I hope to eventually

incorporate spring mass damper calcs and Weight distributions for estimating the real suspension movement in turn and bump/droop for a set of road

conditions.

If I feel really adventurous I will even try to put in some data about friction coefficients for the tyres to get a rough idea about grip

limitations.

I am going to add a Save profile button to the project tonight and then I will mail the promised copies out.

[Edited on 28/4/04 by Digger Barnes]

pbura - 28/4/04 at 01:29 PM

That whole area of springing and weight transfer is very interesting. I haven't learned much about it yet because it doesn't come into play

until way down the pike for me, but I have found this page and site to be very provocative:

http://www.smithees-racetech.com.au/wttransworksheet.html

Pete

Digger Barnes - 29/4/04 at 07:31 PM

jcduroc and pbura check your email it is finaly ready to play with.

Digger Barnes - 29/4/04 at 07:40 PM

quote:

Originally posted by pbura

Well, I took a shot at Dave's suspension geometry, had a lot of fun, and got more behind with earning my daily bread

P.S. dont you want to calculate the rear suspension with 1" of droop rather than 1" of bump as the car will dive into a corner when on the

brakes lifting the rear?

[Edited on 29/4/04 by Digger Barnes]

pbura - 30/4/04 at 12:32 AM

quote:

Originally posted by Digger Barnes

P.S. dont you want to calculate the rear suspension with 1" of droop rather than 1" of bump as the car will dive into a corner when on the

brakes lifting the rear?

Mmmmm, because I was thinking about accelerating out of turns?

Fact is, I didn't even think about it, but I'll freely admit that I'm a tyro.

I noticed that you do the droop and roll for the rear in your program, which is very cool!  It's a great start. When you get into more

interactive modeling and to use other than Sierra uprights, as are your plans, it will be a real winner. It would be fantastic to be able to watch an

animation, or fix a frame with the RC and camber figures, and watch them change as you alter pivot locations.

It's a great start. When you get into more

interactive modeling and to use other than Sierra uprights, as are your plans, it will be a real winner. It would be fantastic to be able to watch an

animation, or fix a frame with the RC and camber figures, and watch them change as you alter pivot locations.

The camber figures for Dave's car at 1" droop, 2 degrees roll are +2.000 degrees on the loaded side, -0.925 deg. on the unloaded side, btw.

Are these OK? They're better than in your example, at least

If anyone would like to throw in their two pence, and tell me to get back to the drawing board, or whatever, WRT the proposed changes to Dave's

suspension, I'd appreciate it. Please note that I was going for good performance while keeping the changes simple. The sum total of the changes

were:

--Raise the ride height 0.75"

--Raise the bottom wishbone mounting bracket 1.5" (no change in the wishbone).

--Move the upper pivots in by a few inches along the same tubes a few inches, and make new wishbones to suit.

Opinions are like a**holes; everybody's got one. Anyone game to share theirs? Opinion, that is!

Pete

jcduroc - 30/4/04 at 04:35 PM

quote:

Originally posted by Digger Barnes

jcduroc and pbura check your email it is finaly ready to play with.

No light at the end of the tunnel yet.

Just f*****g Viagra advertisements...

Joćo

Digger Barnes - 30/4/04 at 05:02 PM

No light at the end of the tunnel yet.

Just f*****g Viagra advertisements...

Joćo

Didn't you get the program? if not u2u me your address again

cheers gareth

jcduroc - 30/4/04 at 06:54 PM

quote:

Originally posted by Digger Barnes

No light at the end of the tunnel yet.

Just f*****g Viagra advertisements...

Joćo

Didn't you get the program? if not u2u me your address again

cheers gareth

I got it (just problems w/ too many trash msgs in my ISP provider, I guess)

I had a quick look but I'm going to try it fully tonight.

BTW, where does ET41 come from? I thought Sierra normal wheels were ET38.

Joćo

P.S.: I'll post you my remarks on Sunday (I hope).

Digger Barnes - 1/5/04 at 06:15 AM

quote:

Originally posted by jcduroc

BTW, where does ET41 come from? I thought Sierra normal wheels were ET38.

ET 41 comes from the wheels I had on my donor (XR4x4) well thats what it has stamped on them anyway.

Northy - 1/5/04 at 08:53 AM

Digger,

Could I have a copy please?

Cheers

F1 Mini - 1/5/04 at 09:27 AM

I would love a copy Please Sir.....

[Edited on 1/5/04 by F1 Mini]

Digger Barnes - 1/5/04 at 11:19 AM

Sure thing Graham and F1 just U2U an address and I'll send a copy out.

Cheers

P.S. Pete that Milliken & Millikin book will be winging its way to me very soon, I simply must have it.

jcduroc - 2/5/04 at 02:45 PM

quote:

Originally posted by Digger Barnes

P.S. Pete that Milliken & Millikin book will be winging its way to me very soon, I simply must have it.

Gareth

I have it on paper; anything in particular you want to know right now? (Any formula...?)

Joćo

Digger Barnes - 2/5/04 at 03:50 PM

Thanks Joao (sorry I don't know how to do the a properly in your name)

I should have the book on Tuesday or Wednesday. As it is a bank holiday over here I shall be relaxing for a day or two (very little on the car or the

misses will kill me) so thanks but i should be ok.

But I am sure you have a book or two I would not mind a few pages from so I might email on the scrounge later on in the build (Aerodynamics

anyone).

Cheers

Gareth

jcduroc - 3/5/04 at 09:00 PM

quote:

Originally posted by Digger Barnes

Thanks Joao (sorry I don't know how to do the a properly in your name)

Gareth

ALT+0227 (on the num keypad) like this: ć

Of course keyb po doe it directly.

Joćo

[Edited on 3/5/04 by jcduroc]

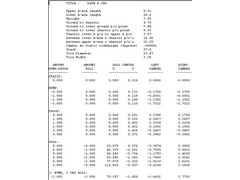

dblissett - 8/5/04 at 08:16 AM

hello pete i now have the avon dimentions for you

the bottom wishbones,brackets and upright pivot points realative to the road are all the same although ride height is 4 1/2 to 5 inches

the top wishbones are longer but mounted higher at their brackets

ps i am half way through your changes as my new daughter is slowing things down

could you compare this with changes i am doing as northy and other are interested

cheers dave

Rescued attachment avon.JPG

SilverFox - 7/8/04 at 05:36 AM

Pete, Have reviewed this topic several times - excellent stuff. When you refer to book suspension, is your analysis for the Cortina or the Sierra

uprights? Do folks generally use the same (per book) or different inboard pickups to accommodate the wider Sierra configuration or when going ++ etc?

Can you get a "non-migrating" front RC down to say 2" with the Sierra upright on book chassis swivel points

Alf

pbura - 7/8/04 at 11:25 AM

quote:

Originally posted by SilverFox

Pete, Have reviewed this topic several times - excellent stuff. When you refer to book suspension, is your analysis for the Cortina or the Sierra

uprights? Do folks generally use the same (per book) or different inboard pickups to accommodate the wider Sierra configuration or when going ++ etc?

Can you get a "non-migrating" front RC down to say 2" with the Sierra upright on book chassis swivel points

Alf

Hi Alf,

I did up the book front suspension with Cortina uprights in the suspension programs. To be honest, I may be off very slightly because of bracket

heights, but the results were close to what MikeP got in a similar exercise. Differences were so minor that I haven't made the effort to get it

100% accurate. I'm not building a book car anyway

For a wider car, increasing the distance between the chassis pickups (as in a McSorley +4) gives very similar geometry.

Changing the uprights, e.g., using cut-down Sierra struts, will probably give a different geometry (camber and RC behavior), but I've never

studied it out.

I encourage everybody who is building non-book to learn all they can about their suspension. If I were to design Dave's rear from scratch (his

was already built), I'd probably go for less camber gain in bump, but who's to say I'd be right?

If you or anyone else needs a hand setting up one of the suspension programs, or would like some feedback on a suspension setup, please feel free to

e-mail or U2U.

All the best,

Pete

iwbunting - 7/8/04 at 07:52 PM

I am building a mcsorley +442 with rear irs.I have also read the bibles and have based my wishbones on book calculations and ......... I have built in

some adjustments,firstly the top wishbone is approximately 2/3rds of bottom and is fitted with a rose/ball joint at the upright end giving about 25mm

adjustment in length.Secondly and foremost on the chassis side i have welding in sets of brackets with varying hole positions in the vertical plane,by

doing this it has given me the ability to infinately adjust camber,height and roll centres by merely raising or lowering the inner pivot points.

Hope this might be of help.

SilverFox - 8/8/04 at 01:48 AM

Many thx for the clarification Pete. I will do a search for key dimensions of the Merkur/Sierra upright and get back to you

(probably e-mail) with a first cut.

unfortunately don't have MS quickbasic or any of the other tools as yet - a winter project possibly.

Have to tried Digger Barnes' software?

Dave. the only adjustability I am thinking of at present is raising the mushroom insert. My arm lengths are 17 3/4" and 12 1/2" attached

to the book swivel points.

Alf

SilverFox - 8/8/04 at 03:01 AM

Sorry, correction 17 1/2" and 12 3/4"

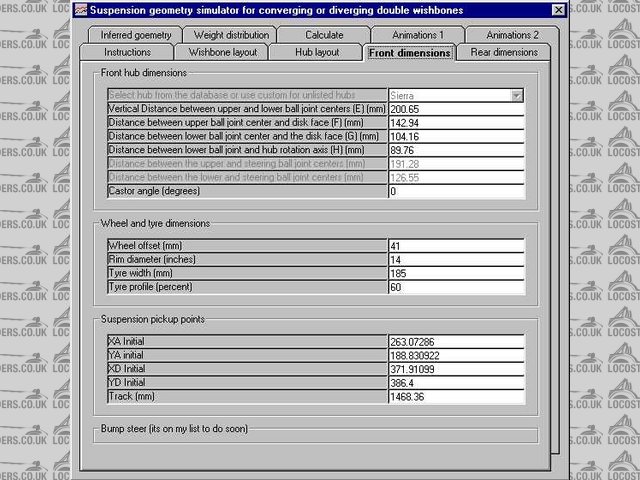

pbura - 8/8/04 at 11:59 AM

quote:

Originally posted by SilverFox

Have to tried Digger Barnes' software?

Yes, and it was looking very promising, too. In fact, it's presently based on Sierra uprights, so you ought to e-mail him for a copy.

Following are some screen shots showing the upright dimensions:

Rescued attachment Sierra1.jpg

pbura - 8/8/04 at 12:02 PM

2nd pic:

Rescued attachment Sierra2.jpg

SilverFox - 8/8/04 at 10:03 PM

Many thanks Pete for the upright dimensions. You are a fountain of information. I am out of Town for a week and will then formaulate an option on

which,

I would appreciate you analysis and assessment. Great stuff.

dblissett - 16/8/04 at 09:00 PM

just a big thanks to pete bura

i have just finished your changes pete as you can see its only tack welded and the studing was to keep the brackets in line

but the main thing is it all seems to work now

its taken a lot longer than i thought but its been worth it i have been trying to sort out this backend for so long the rest of the chassis has gone

rusty

cheers pete i ow you one

Rescued attachment 04a2002_0524_074843.JPG

pbura - 16/8/04 at 11:51 PM

Hey, Dave, you'll have to post another pic at ride height when you get there. Glad you're ready to move ahead.

I just reviewed my recommendations to you again (details on page 5 of this thread) and was relieved to see that they still look pretty decent from the

perspective of a few more months. If I were to do a scratch design, I'd try for a bit less camber change in bump, but it's not a big deal

(about 1/3 degree per inch difference).

Crossing my fingers and hoping for a good result. Wish I could drive it!

All the best,

Pete