Hi,

Has anyone on here used the Euroquip 600 self assembly brake hose fittings from Rally Design? If so, did you get any instructions with them?

In particular, I would like to know if the braided outer goes inside the olive or outside (I think outside as it's very tight) and whether the

braiding should be trimmed back a bit to let the screw on fitting compress the olive on its own, or whether I should leave the braiding full length

and let it get trapped between the olive and the screw on fitting.

Also, what is best for cutting the hose to length? I get good clean results using a nice sharp pair of tinsnips but I then have to un-squash the pipe.

I don't think this should be a problem but thought I'd ask.

I'm a bit annoyed that something so critical to safety doesn't come with any instructions. Even a 13Amp plug comes with instructions these

days...

Cheers,

Craig.

i think they have to be crimped for sva,those will fail

Hi Conrodkid,

I've just received my SVA Manual and it says something along the lines of "they are okay if they have a central support pipe" which

these do have. I would have just bought crimped hoses but my setup is not a standard one and I want flexibility (pardon the pun) in the

arrangement.

Cheers,

Craig.

k i stand corrected,may be best to get onto raldes and have words

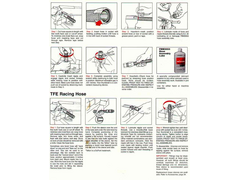

Will be Ok for SVA. The attached picture gives an idea on assembly. If stuck give rally design (www.raldes.co.uk) a call tomorrow and get them to fax

you a data sheet. As a precaution (if you are really particular) place a small amount of loctite thread lock on the threads prior to tightening.

I've never had a failure. I have a car with this type of fitting (JC Midge) on brakes for last 15 years.

The braid is a pain to cut -a number of methods - really sharp chisel and alloy block as support, dremel cut off tool (great), heavy duty snips

etc.

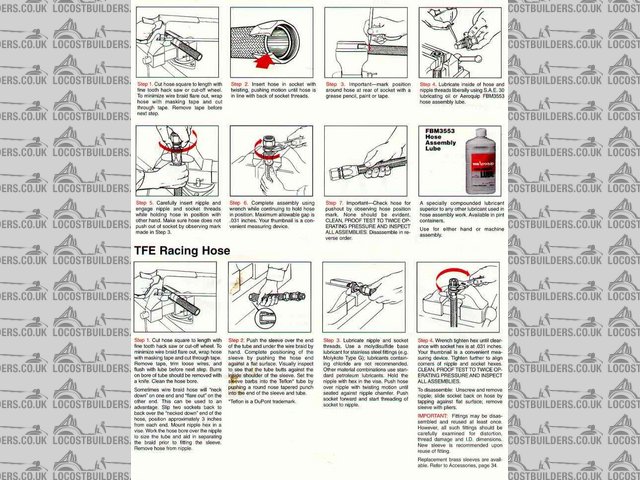

PS: BRAID SHOULD BE ASSEMBLED AS PER TFE HOSE PIC 2

[Edited on 12/4/04 by Terrapin_racing]

Rescued attachment assinstr.jpg

Thanks for that.

Can I assume that this is not "exactly" the same as the Euroquip stuff as I don't remember there being any barbs inside the sleeve.

I'll contact RalDes tomorrow and see if they have a datasheet just to make sure that I'm doing it right...

Also, do you just test yours in situ. I was planning to just wait until my whole hydraulic system was assembled and then pressure test the lot by

sitting with my foot on the pedal hard for as long as my leg muscles will last and then checking for drips (ooer!)

Cheers,

Craig.

Craig, instructions are for earl's hose but same principle applies to braid arrangement and tightening. I must admit I have access to testing

gear in work (hydraulic) but have never used it on brake fexibles. As you state, I always test mine on the car - never had a leak yet. I still keep an

eye on the master cylinder level like a hawk for the first few days on the road though!

Best of luck, I'm sure all will be OK.

Just plumbing a fuel system at present - cutting the larger 100 series hose is a B*****d.

Craig,

I've got some illustrations that should be exactly what you need - if I get a chance I'll scan them for you.

Email me if I forget, I'm busy at the moment and very disorganised.

Kingr

Kingr,

That would be great as I didn't get a chance to chase Rally Design today. I actually assembled three small hoses last night and it doesn't

appear to be a problem. The hardest bit is separating the braiding enough to let the little olive thingy in between the hose and the braiding but once

that is done it is easy. I did use threadlock but only a very small amount to help lubricate the threads while puting them together and obviously to

keep them together.

Has anyone gone through SVA with these type of hoses and if so would you recommend that I get a spare fitting to take with me and show to the

inspector to convince him that they are of the appropriate type?

Cheers,

Craig.

quote:

Originally posted by craig1410

Has anyone gone through SVA with these type of hoses and if so would you recommend that I get a spare fitting to take with me and show to the inspector to convince him that they are of the appropriate type?

Cheers,

Craig.

I have not been through the SVA but it states that these fittings are ok, well it states that fittings with an "inner support sleeve" are ok, and the Euroquip 600 fittings have an inner support sleeve (the long thin bit that pokes inside the Teflon liner). I would order an extra fitting and take it with you to the test, you can show the tester what you have used and that it has the inner sleeve.

NS - I'm sure you are right -should be fine for SVA

Craig, fitted the RalDes braded pipes in my RS2000 easy to do and well worth the extra cost, but don't forget about swivelling ends. I forgot and

had male ends on the pipe from the m/cylinder to the back of the car, made it a right pain to put in and even worse to take out. So banjo type ends

are fitted at the master cylinder now.

Far better than the solid brake pipes

Rob,

Thanks for the info.

Are you saying that you use braided hose for your entire pipe run?

If so then this surprises me because I'd have thought that this would lead to a softer pedal than if you use metal pipes for the fixed bits and

flexible only where needed. I am only using five flexy hoses for the following:

1. Chassis to de-dion axle tee-piece

2. De-dion axle to calipers (x2) as the calipers are the sliding type.

3. Front chassis to front caliper (x2)

I'm also going to use it for my clutch from the chassis to the slave cylinder.

Everything else will be copper pipe of 3/16" diameter and will run down the tunnel and around the engine bay as usual.

Surely copper is more resistant to pressure than PTFE or whatever is in the euroquip hoses?

Cheers,

Craig.

Craig, The full run in the car is braided. As i have no servo The brake pedal is very firm and there is very little pedal movement required to stop the car, But lots of effort.

Craig, you are probably right, but I think it is shades of the same colour, there is not much "swellability" to the stainless braided teflon or copper! I would probably use copper on the long runs (I have on other cars) but only cos it's cheaper!!

They tried a rally car with fully braided hoses and condemned it as a failure. They said that under violent braking the hoses could be seen to move (run inside the car) physically squirming like snakes. Having no servo doesn't make any difference to brake efficiency, a servo just makes the pedal easier to press and robs you of feel. It's standard now because everyone expects it along with power everything else.

so has anyone found out how to fit the raldes stuff or shall i just experiment?

http://www.earls.co.uk/bike/09_Assembly_instructions.pdf

See if this is any help.

Fitting the ends is easy. Just cut end pipe end clean across at 90deg. Push the backing nut over the pipe, spread the braiding out away from the ptfe

liner. Then push the olive on to the ptfe pipe so that it is fully into the olive, you can see the pipe inside the olive it should be right up to the

metal. Then tighten up on to the fitting. Don't tighten the nut right up to the fitting leave about 1 turn Aprox 1mm from the nut to the

fitting.

I was told by RalDes that the fittings can be taken apart and put back together again without changing the olive. Iím not to sure about this bit, I

work with pipe fittings a lot and there are not may manufactures that recommend this.

Rob