Track rods

iiyama - 16/12/08 at 06:33 AM

Guys,

bought a steering rack sometime back that had been modyfied from standard track rods to lengthend ones. Basically this of course meant not having to

use extensions and I liked the idea!

Now heres the rub. The track rods on the rack wernt long enough for my application, (Dax Rush), so I got some new ones machined up. The rod ends are

standard Sierra units and so the rods themselves were machined to M14 male threads :-

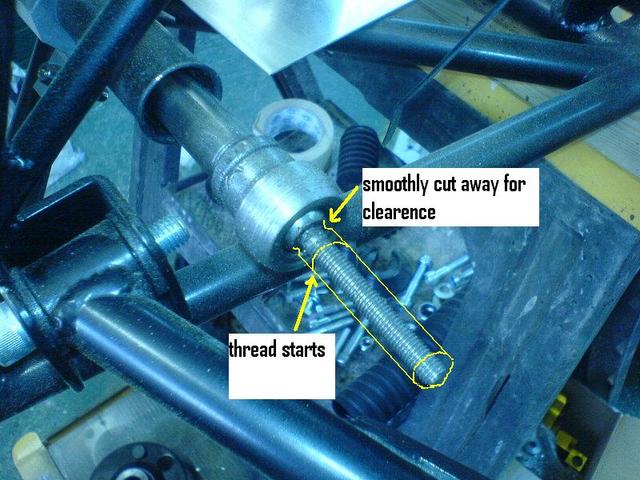

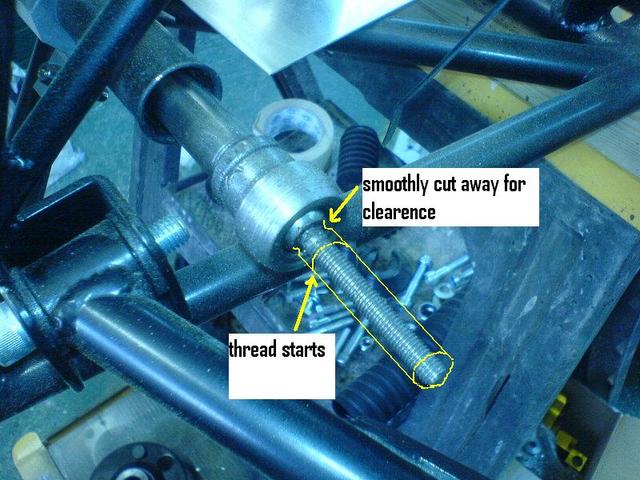

However the rack end is where Im getting concerns as the thread from the ball joint is M8 male. Track rod was drilled and threaded to accept but it

just seems a little small.

Whats the concencous??

If they are too small, whats an acceptable size? M10?

clairetoo - 16/12/08 at 06:37 AM

Thar does look a bit weedy - I'd say make it as big as you can !

iiyama - 16/12/08 at 06:46 AM

Trouble is that if I make it too big then it may foul the rack on full bump/droop.

Mr Whippy - 16/12/08 at 07:35 AM

sorry, don't think I'd be happy with that tbh. I'd have at least expected the same size as used on the original track rod. The thread

going right to the balljoint is also leaving sharp edges just where there should be a nice smooth radius to clear the lip of the cap. I think that

area will be prone to fatigue, it would be best if the thread started further along as in my pic

Rescued attachment trackrod.jpg

blakep82 - 16/12/08 at 08:31 AM

minimum M12 i'd say.

what's interesting is you say you liked these because it didn't use extensions, but the whole rod itself is actually an extension in this

case. use stadard rods i think

Bluemoon - 16/12/08 at 09:45 AM

I'd be very careful and I would want to find out how they make original ones... Not had the real one's apart but the material choice might

be impotent, i.e. it will probably be hardened.

The problems I can see are if it fails at the point when you hit a pot-hole or similar (shock load might be considerable)...

The kit manufactures just make a machined piece to extend the existing rods, they don't mess with that part inside the rack... The piece they add

is huge and I think made from mild steel..

Personally Id stick with the tried and tested root of extension pieces as per the main manufactures..

Just my opinion...

Dan

02GF74 - 16/12/08 at 10:21 AM

wot you are saying is the thingy was drilled to take an M8 threaded rod or machined down to M8 - and then the new arm is fitted on top!?

do the sum.

escort rack is M14. not taking into account the metal lost due to the trhead, the difference between an 8 mm and 14 mm rod is a factor of 3 !!!

I'd be very uncomfortable using that. In fact I doubt there is any car that uses track rod ands as small as 8 mm!!

iiyama - 16/12/08 at 04:53 PM

Well it was second hand and came of a westy so it has been used! :0

Anyway thanks for the replys, pretty much summed up what I thought!

Regarding the extensions, I was refering to the threaded extensions that screw onto the end of the trackrod! Not the trackrod itself!

[Edited on 16/12/08 by iiyama]

DarrenW - 17/12/08 at 10:28 AM

So is the M8 threaded bit and ball a new piece that someone has made? Why couldnt original be used (cant remember what they look like inside the

rack).

If something looks wrong then it most probably is.

If something is safety critical and looks wrong it can kill.

As others have said, the M8 bit in the pic looks too thin and also appears to have a stress raising point near the ball. If it i snew and not made on

a controlled process with fully tested materials then you are right to raise questions. I wouldnt be happy with that configuration and would probs

suggest reverting back to the tried and tested method.

I have to say i am even against the modification of intemediate steering shafts so the thought of modifying racks scares the hell out of me.

I know everyone gets hung up on cars being designed with compromise in mind (ref performance vs comfort vs economy) but if anyone has ever worked in

an OE production environment you will know the operators cant even fart or wipe there noses without an 8D or similar concern report being raised. It

is regulated for a reason so please exercise caution when building.