stuart_g

|

| posted on 16/6/08 at 09:13 PM |

|

|

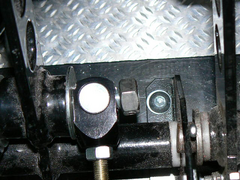

Bias bar locking

I am trying to find a solution to lock the bias bar, something so simple is taking so long.

The problem is finding a spacer to go between the lock nut and the clevis, there is little difference in the diameter of the bias bar and the inside

of the clevis.

I can get a lock nut on but the way the bias bar moves I can not lock it up against the clevis as it will stop it working. Would it be ok if I left a

gap as in the picture. The bias bar could be adjusted still after but not very far to make a noticeable difference.

What have you done to lock the bias bar?

[Edited on 16/6/08 by stuart_g]

[Edited on 16/6/08 by stuart_g]

Rescued attachment P1010096.JPG

|

|

|

|

|

worX

|

| posted on 16/6/08 at 09:20 PM |

|

|

I could make you a couple of Nylon washers of various thickesses if that would work?

Although I'm not in work for a while so you'd have to wait I'm afraid!

Steve

|

|

|

Howlor

|

| posted on 16/6/08 at 09:20 PM |

|

|

I am sure mine came with some spacers, or I may just have made some.

Steve

|

|

|

jambo

|

| posted on 16/6/08 at 09:26 PM |

|

|

could you grind down a nyloc so its thinner leaving the nylon side.

|

|

|

kenton

|

| posted on 16/6/08 at 09:27 PM |

|

|

I used a bias bar locking kit from cbs. Nut, roll pin and shout lenght of thin wall copper tube. Expensive, about £6 i think.

kenton

|

|

|

matt.c

|

| posted on 16/6/08 at 09:39 PM |

|

|

Ah thats why mine aint working right.

I seem to have loads of thread one side but sod all the other side. It just doesnt seem to work that well or i have it setup wrong.

|

|

|

stuart_g

|

| posted on 16/6/08 at 09:47 PM |

|

|

I have looked at making a spacer/sleeve, the problem is that the threaded bias bar is 7/16 which is about 11mm and the clevis is 12mm wide leaving a

1/2mm wall thickness, without a lathe this is impossible to make and my SVA is this Friday, Yikes! and my SVA is this Friday, Yikes!

[Edited on 16/6/08 by stuart_g]

|

|

|

Johneturbo

|

| posted on 16/6/08 at 10:24 PM |

|

|

Stu,

i've just got halfnuts  with a little gap with a little gap

as long as it's not right up tight should be fine. i'll let you know thursday nite

|

|

|

mad4x4

|

| posted on 17/6/08 at 07:24 AM |

|

|

Mine has the half nuts and then the end of the rod is drilled with a small split pin through so if the nut does move t can;s come off the end of the

bar. A dob of Thread lock also keeps the nuts in place.

Scot's do it better in Kilts.

MK INDY's Don't Self Centre Regardless of MK Setting !

|

|

|

wilkingj

|

| posted on 17/6/08 at 07:32 AM |

|

|

I am fairly sure that the SVA requires Roll Pins through the nuts.

Or at least a permanant locking device.

Check the SVA manual, or ring your local VOSA SVA testing centre. Its worth getting it right first time. Ask them, and they will tell you what they

will accept or not accept. They are generally very helpful.

1. The point of a journey is not to arrive.

2. Never take life seriously. Nobody gets out alive anyway.

Best Regards

Geoff

http://www.v8viento.co.uk

|

|

|

vindicator

|

| posted on 17/6/08 at 10:56 AM |

|

|

When you go to the SVA, they will test the front and back brakes and will confirm whether the bias bar is in the correct position, you take with you a

battery drill, ammer, roll pin and small drill to suit. You can then drill thru the yoke and bar and tap in the roll pin. Problem solved and if the

roll pin should happen to fall out it will be too late as you will have passed the SVA. (One reason you may not be able to do the drill operation may

be you can't get at the peddle area)

I tried the weld nut approach and my local garage only did one side and did it too tight that the bias bar did not function right. Second attempt

worked first time with drill and hammer.

HTH

TimR

timr.spaces.live.com

|

|

|

BenB

|

| posted on 17/6/08 at 11:13 AM |

|

|

If it's for SVA you may not need to lock the bias bar if you can cover it up. I made up a little ali box which covered the bias bar and covered

it in vinyl. Once rivetted in place the bias bar becomes "non-adjustable" and it's tested as it is. Would have been a bit of a

bugger if it had failed and needed adjustment....

|

|

|

stuart_g

|

| posted on 17/6/08 at 03:23 PM |

|

|

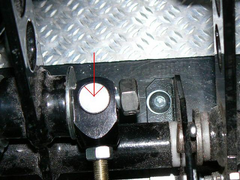

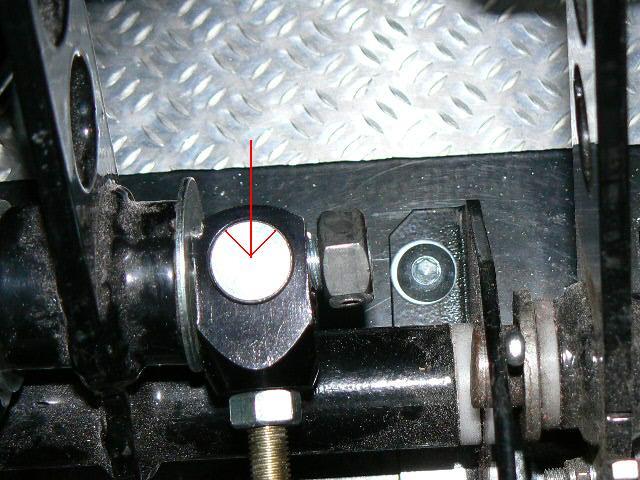

quote:

Originally posted by vindicator

When you go to the SVA, they will test the front and back brakes and will confirm whether the bias bar is in the correct position, you take with you a

battery drill, ammer, roll pin and small drill to suit. You can then drill thru the yoke and bar and tap in the roll pin. Problem solved and if the

roll pin should happen to fall out it will be too late as you will have passed the SVA. (One reason you may not be able to do the drill operation may

be you can't get at the peddle area)

I tried the weld nut approach and my local garage only did one side and did it too tight that the bias bar did not function right. Second attempt

worked first time with drill and hammer.

HTH

TimR

timr.spaces.live.com

I like the idea of drilling the yolk. It would only need one roll pin to lock it aswell.

Just to clarify I have arrowed where I think you mean. Is this OK with the examiner?

Rescued attachment Roll pin position.JPG

|

|

|

rusty nuts

|

| posted on 17/6/08 at 05:56 PM |

|

|

I drilled and tapped the trunnions (yokes) and put in a grub screw and put a nylock on for good measure . I had to adjust bias at SVA but the

inspector was happy with method of locking. Whether this is still the case I'm not sure but in my mind it's a better solution than a roll

pin. PS I drilled them in a lathe before fitting.

|

|

|

Mix

|

| posted on 17/6/08 at 06:27 PM |

|

|

Hi

Drilling through the clevis barrel nut as above will weaken the balance bar wheras drilling in an area outside of the barrel nuts will not......your

choice.

As for the bar being adjustable....provided the brakes pass the test in both extremes the bar can be adjustable, (but not from the driving position),

at least that's how I read it

Regards Mick

|

|

|

se7ensport

|

| posted on 18/6/08 at 04:09 PM |

|

|

I put a large washer between the clevis & the nut which I drilled and put a roll pin through.

they shouldn't/won't let you drill it at the test centre (I did ask in advance but was told "not a chance!" . .

Good luck

|

|

|