timwest167

|

| posted on 22/3/05 at 03:58 PM |

|

|

Spiral Wrapping

Having looked at various build diaries some people put spiral wrapping on the copper brake pipes and fuel pipes where they go around corners... some

people don't.

Is this an SVA requirement now, or can I leave the copper pipes bare?

Tim

|

|

|

|

|

locoboy

|

| posted on 22/3/05 at 04:03 PM |

|

|

you can leave them bare from what i have heard / seen, i cant think of any reason for wrapping them in spiral wrap other than if there is the

possibility of something chafing them - but that wouldnt be limited to the corners im sure.

ATB

Locoboy

|

|

|

Danozeman

|

| posted on 22/3/05 at 05:04 PM |

|

|

Its just so they dont chaff i would say. maybe to make them look a bit better too..

Dan

Built the purple peril!! Let the modifications begin!!

http://www.eastangliankitcars.co.uk

|

|

|

britishtrident

|

| posted on 22/3/05 at 05:12 PM |

|

|

Slip windscreen washer tube over the pipes before flairing.

Copper brake or fuel pipe is iffy due to fatigue and age hardening problems I learned that working pre 1930 cars ---- tthats why Steel Bundy brake

was developed.

These days I use Kunifer alloy which is much safer is easy to work and dosen't corrode. Kunifer is easy to identify has a silver-gold hue

rather a true red copper colour you will find on some copper brake pipe.

For more info see http://www.dimebank.com/BrakePlumbing.html

[Edited on 22/3/05 by britishtrident]

|

|

|

viatron

|

| posted on 22/3/05 at 07:52 PM |

|

|

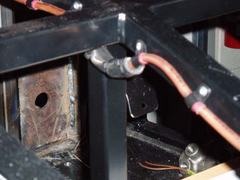

Brake Pipes

Cuniffer (COpper/Nickel usually in 70/30 ratio) has got to be the way forward, nearly as easy to work as copper but much more corrosion resistant. I

am building a Tiger Cat and have used split fuel pipe held in place with small cable ties but only in areas where there is a chance of chaffing (see

pic) but cant see any benefit in spiral wrapping the whole run, if anything i would think it would encourage water, mud etc to cling to the pipe run

which even using Cu/Ni cant be a good idea!!

Mac

Rescued attachment Brake_Pipe_Protection.jpg

|

|

|