pekwah1

|

| posted on 27/8/12 at 09:50 AM |

|

|

Wiring and cable ties

Hi Guys,

I am reading slightly conflicting stuff...

If i have my wiring in that convoluted tube stuff which is then wrapped with leccy tape, is it ok to attach this to my chassis rails with cable ties?

I would not be using sticky fixers but going round the entire rail with the cable ties.

Cheers,

andy

|

|

|

|

|

ReMan

|

| posted on 27/8/12 at 10:09 AM |

|

|

My understanding is no.

They need to be held to the chassis with proper fixings and just sticky is not enough they need to be permanent like screwed or riveted.

It's about using "production" methods I think and cable ties to the chassis aren't it.

Apart from not looking great imho

What are the other opinions?

www.plusnine.co.uk

|

|

|

myke pocock

|

| posted on 27/8/12 at 10:40 AM |

|

|

P clips, Nutserts and the wiggly tube although someone will undoubtedly say that putting Nutserts into a tube drastically reduces the strength of the

tube. Did mine this way and passed SVA no problem.

|

|

|

dhutch

|

| posted on 27/8/12 at 10:45 AM |

|

|

I can pass no comment on the requirments of IVA, although I can asure you that while the sticky back bases are awfull, there are plenty of companies

using cable ties in production... (not really helpfully but its all ive got).

Daniel

|

|

|

FuryRebuild

|

| posted on 27/8/12 at 10:56 AM |

|

|

I agree with Mike - I only use nutserts when I have to, in non, structural ways.

Another way is to use a self-tapping screw with the sticky pads. At least you're replacing metal with metal.

If you're a place in your build when you can weld to the chassis, take a look at this

linkthis link to see how I decided to do it;

brackets welded to the chassis, followed by p-clips to hold whatever.

Also, use the plastic shielding that's like slit black plastic conduit to keep everything inside, suspended every 12". I also used

cable-ties every 6" to keep it tidy.

what's more, steer away from electricians tape; it's not designed for the heat and moisture of an engine bay and when the adhesive starts

to melt it will clag everything up and not support it properly. Back in the day, electricians tape is totally a fail.

When all you have is a hammer, everything around you is a nail.

www.furyrebuild.co.uk

|

|

|

Madinventions

|

| posted on 27/8/12 at 10:58 AM |

|

|

I used these type of cable ties bases, and fixed them to the chassis using a self tapping screw. Much quicker than rivnuts, and passed SVA no

problem. Sticky pads would work just as well, but need to be screwed to the chassis or they'll fall off within a few months and you'll

have rattles everywhere! (in my experience).

Ed.

Mojo build diary: http://www.madinventions.co.uk

Solo music project: Syrrenfor http://www.reverbnation.com/syrrenfor

View my band website:

http://www.shadowlight.org.uk

http://www.eastangliankitcars.co.uk/

|

|

|

PeteS2k

|

| posted on 27/8/12 at 11:12 AM |

|

|

Loom in split, convoluted tubing, wrapped in tape, then I used these...

riveted to the chassis rails at appropriate intervals.

|

|

|

Wadders

|

| posted on 27/8/12 at 11:42 AM |

|

|

Typical IVA nonsense, you could argue that drilling the chassis every 6 " just to hold cables up could affect the structural rigidity

of the tubes, and allow water in over time causing internal corrosion.

Cable ties might not look proper but they do the job without the need for drilling holes.

Have a look under any TVR, i think they must have had shares in a cable tie company

If your building from scratch i suppose the best way would be to weld on bits of tube for the loom and pipes to pass through.

Al.

|

|

|

Daddylonglegs

|

| posted on 27/8/12 at 11:43 AM |

|

|

If you read the post guys he is asking if it is OK to put cable ties around the whole rail not through any sort of fixings.

From my IVA experience I cannot see a problem. Mine had some rivetted cable tie clips and some ties completely around the rail and the tester was OK

with that.

JB

It looks like the Midget is winning at the moment......

|

|

|

dhutch

|

| posted on 27/8/12 at 12:54 PM |

|

|

quote:

Originally posted by FuryRebuild...another way is to use a self-tapping screw with the sticky pads. At least you're replacing

metal with metal.

Not so much that you replacing metal with metal (all the rivnuts ive seen have been metal anyway) but the hole in said structural member is much

smaller. I wouldnt want to make big (rivnut) holes in my chassis for the loom, although neather would I want to weld to it.

Daniel

|

|

|

rachaeljf

|

| posted on 27/8/12 at 01:11 PM |

|

|

Speaking as a structural engineer, I would not like any fixing into slender structural members in a space frame chassis without using doublers or some

other method of maintaining the full section capacity. I can't see any issue with cable ties around a chassis member.

For a member that relies on its section properties to resist buckling, bending or tension, a self-tapper does not "replace metal with

metal"! It makes a hole, which even if no material is lost from the section, makes a stress raiser at the very least.

Cheers R

|

|

|

myke pocock

|

| posted on 27/8/12 at 03:23 PM |

|

|

Looks like my car is going to buckle all around me as I have used Nutserts extensively then.

|

|

|

loggyboy

|

| posted on 27/8/12 at 04:48 PM |

|

|

I decieded to to rivnuts, but went for the smallest I could (5mm hole, m3 thread) which meant tiny fixings but looks nice and neat. Used stainess

rubber lined Pclips for the brake lines, and 20mm plastic pclips for the electrical tubing which is unsplit.

Mistral Motorsport

|

|

|

myke pocock

|

| posted on 28/8/12 at 03:26 PM |

|

|

By the way, and you probably know this already, you will have to change your mounting bolts for your shockers as the Nylok plastiv insert isnt

gripping on any thread. If you havent been through IVA yet I have heard that some testers insist on three threads showing outside the nut as well.

|

|

|

loggyboy

|

| posted on 28/8/12 at 03:30 PM |

|

|

quote:

Originally posted by myke pocock

By the way, and you probably know this already, you will have to change your mounting bolts for your shockers as the Nylok plastiv insert isnt

gripping on any thread. If you havent been through IVA yet I have heard that some testers insist on three threads showing outside the nut as well.

Cheers, but all the bolts/buts are only loosely done up at this stage, theres a good 5-6mm of thread still to tighten up (although the picture doesnt

really show that very clearly!)

Mistral Motorsport

|

|

|

The Black Flash

|

| posted on 28/8/12 at 08:52 PM |

|

|

I can't see why a cable tie through a base that's then bolted to the chassis is any better than a cable tie directly round the chassis

rail??

|

|

|

loggyboy

|

| posted on 28/8/12 at 09:18 PM |

|

|

quote:

Originally posted by The Black Flash

I can't see why a cable tie through a base that's then bolted to the chassis is any better than a cable tie directly round the chassis

rail??

I would assume its the fact that the if its around the whole chassis theres nothing to stop tyhe cables working their way around each face of the

tube.

Mistral Motorsport

|

|

|

blakep82

|

| posted on 28/8/12 at 09:32 PM |

|

|

^ and possibly the cable ties all working their way down to the lowest point on an angled tube, leaving none at the top (whick, ok, is very

unlikely!)

i'm 'lucky' in that very few of my chassis tubes have any panelling or anythis attached to them, and they're all round tube,

so i've got rubber lined P clips round the chassis, and then a smaller one holding whatever needs secured

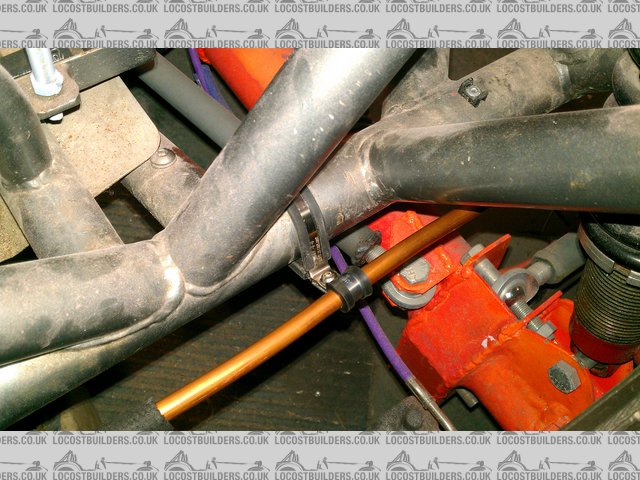

Description

wiring's not in yet, but its how the wiring will be held in mine when it's done. the only holes getting drilled with be in sheet metal

panels. no way i'm risking water getting insode my chassis tubes, although some tie wrap bases have already been pyut in by the last owner of

the chassis, so i'll use them if they're already there, but not adding any more

with a bit of work, and a bit of squishing, a carefully chosen metal P clip chould be shaped to fit round a square tube i should think

[Edited on 28/8/12 by blakep82]

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

The Black Flash

|

| posted on 29/8/12 at 01:53 PM |

|

|

quote:

Originally posted by loggyboy

quote:

Originally posted by The Black Flash

I can't see why a cable tie through a base that's then bolted to the chassis is any better than a cable tie directly round the chassis

rail??

I would assume its the fact that the if its around the whole chassis theres nothing to stop tyhe cables working their way around each face of the

tube.

On a single tube in isolation, I guess it could *possibly* happen. But wire runs aren't like that, they go along several tubes in different

orientations. Think of a cable run that makes a 90 degree bend - rolling around one tube would mean stretching lengthways along another.

As for cable ties slipping down a tube, I really can't see that happening when used with convoluted sleeving.

|

|

|

pekwah1

|

| posted on 29/8/12 at 05:46 PM |

|

|

So........

IVA is 'looming' so should i stick with how my cables are secured now or should i go and get a load of stupid P clips to secure it for the

IVA man?

|

|

|

loggyboy

|

| posted on 29/8/12 at 08:48 PM |

|

|

quote:

Originally posted by pekwah1

So........

IVA is 'looming' so should i stick with how my cables are secured now or should i go and get a load of stupid P clips to secure it for the

IVA man?

When it comes to IVA, i tend to err on the side of caution, I would rather spend a £5 on some plastic pclips, and litte time fitting, than go to all

the hassle and expensce of a retest.

Mistral Motorsport

|

|

|

myke pocock

|

| posted on 29/8/12 at 08:50 PM |

|

|

Perhaps it may be worth a call (or visit) to your IVA man to ask his advice if he is prepared to comment?

|

|

|

PeteMKfazer1000

|

| posted on 3/3/13 at 05:44 PM |

|

|

What was the outcome of this? Are cable ties around the chassis sufficient?

|

|

|