andrew-theasby

|

| posted on 13/4/09 at 11:38 AM |

|

|

Minimum spacing between fuel and electrics

Does anybody know if theres a minimum gap needed between the loom, fuel lines and brake lines down the tunnel. I understand that the electrics need

to be on the opposite side to brakes and fuel, but i cant find this written down anywhere either in the old sva mannual or the v3 iva mannual. Id

like mine to all be routed along the top of the tunnel, obviously with the biggest gap i can, would this be ok? Thanks.

|

|

|

|

|

BenB

|

| posted on 13/4/09 at 11:44 AM |

|

|

AFAIR it's not specifically written in the SVA manual but there is flexibility for judging things "suitable for use" e.g. making a

chassis out of loo rolls isn't specifically prohibited but I doubt it would pass  Most testers like to see a fair bit of space between the

electrics and fuel but it's not specified. Never did understand it anyway. To rupture a fuel line is unfortunate, for this to happen as the loom

busts open throwing sparks all over the place is extremely unlikely. Most testers like to see a fair bit of space between the

electrics and fuel but it's not specified. Never did understand it anyway. To rupture a fuel line is unfortunate, for this to happen as the loom

busts open throwing sparks all over the place is extremely unlikely.

|

|

|

andrew-theasby

|

| posted on 13/4/09 at 11:49 AM |

|

|

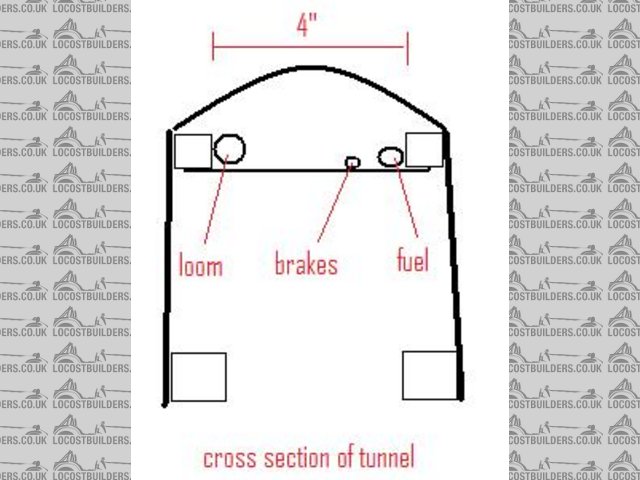

something like this

Rescued attachment tunnel.jpg

|

|

|

richardlee237

|

| posted on 13/4/09 at 11:51 AM |

|

|

The main concern is that a wiring short will cause local sparking/heating which will burn the fuel or hydraulic pipes thus setting the fuel or hyd

fluid alight.

Had exactly this on a racing powerboat when the short burnt through the capillary pipe of the water temp gauge and set light to the alcohol in it. Not

funny when your are in a boat with 50 gallons of fuel on board.

Quote Lord Kelvin

“Large increases in cost with questionable increases in performance can be tolerated only in race horses and women.”

Quote Richard Lee

"and cars"

|

|

|

craig1410

|

| posted on 13/4/09 at 11:53 AM |

|

|

quote:

Originally posted by BenB

AFAIR it's not specifically written in the SVA manual but there is flexibility for judging things "suitable for use" e.g. making a

chassis out of loo rolls isn't specifically prohibited but I doubt it would pass  Most testers like to see a fair bit of space between the

electrics and fuel but it's not specified. Never did understand it anyway. To rupture a fuel line is unfortunate, for this to happen as the loom

busts open throwing sparks all over the place is extremely unlikely. Most testers like to see a fair bit of space between the

electrics and fuel but it's not specified. Never did understand it anyway. To rupture a fuel line is unfortunate, for this to happen as the loom

busts open throwing sparks all over the place is extremely unlikely.

Isn't it more to do with trying to keep them separate in a crash? If they were bound together then any "crush" would potentially

cause the power to short out on the fuel line which, if broken, would very likely cause a fire. Of course having them 200mm or so apart doesn't

make this scenario impossible either.

I think if you keep them on opposite sides of the tunnel and keep them a similar distance away from each other every where else (where possible) then

you'll be okay. I don't think it would matter too much if they crossed over each other once or twice (not touching) but avoid any parallel

runs where they are closer than 2 or 3 inches. I think it also helps if you have your loom well secured and protected with the likes of the convoluted

trunking rather than just spiral wrap or tape. You should also not skimp on securing the fuel lines.

HTH,

Craig.

|

|

|

andrew-theasby

|

| posted on 13/4/09 at 12:10 PM |

|

|

That was quick, thanks for the advice, i could only possibly get them about 40mm further apart, mounting them off the side panels, but i dont really

like that as its getting closer to the prop. Just remembered though theres a fuel return line to cram in there too. With regard to the fire risk, i

was planning to make the tunnel lid out of wood so it could be shaped and smoothed easily round the gear lever and handbrake. Would that be ok? ps i

think ill use solid fuel lines and convoluted tubing like you suggest.

|

|

|

omega0684

|

| posted on 13/4/09 at 12:14 PM |

|

|

i have mine routed the same as in your diagram accept my fuel line in on the lower edge and i even told the insector that and he said they would be

fine as long as they are securely fitted

|

|

|

andrew-theasby

|

| posted on 13/4/09 at 12:16 PM |

|

|

Great, i can get back out into the garage then and carry on now. Thanks

|

|

|

craig1410

|

| posted on 13/4/09 at 12:20 PM |

|

|

quote:

Originally posted by andrew-theasby

That was quick, thanks for the advice, i could only possibly get them about 40mm further apart, mounting them off the side panels, but i dont really

like that as its getting closer to the prop. Just remembered though theres a fuel return line to cram in there too. With regard to the fire risk, i

was planning to make the tunnel lid out of wood so it could be shaped and smoothed easily round the gear lever and handbrake. Would that be ok? ps i

think ill use solid fuel lines and convoluted tubing like you suggest.

Wood should be fine as long as you seal it with varnish or paint to prevent any vapours becoming trapped or oil soaking in. The type of fire to be

afraid of is when your propshaft fails and rips open the hydraulic lines, fuel lines and opens up the electrics. You then have limited or no brakes

and you have afterburners coming out the back of your tunnel caused by forced airflow through the nosecone mixing with the brake fluid and fuel in the

tunnel. If you are lucky the propshaft will have knocked out the feed to the fuel pump...

Doctor Pepper, what's the worst that can happen...

Oh, and then the propshaft digs into the ground and pole-vaults the car upside down...

You'll be fine! (You didn't make your own propshaft did you?)

Cheers,

Craig.

[Edited on 13/4/2009 by craig1410]

|

|

|

speedyxjs

|

| posted on 13/4/09 at 12:22 PM |

|

|

Could you not run the loom across the top of the tunnel and the fuel and brake pipes along the bottom? If the loom were to get hot, heat rises and so

wouldnt affect the pipes.

How long can i resist the temptation to drop a V8 in?

|

|

|

andrew-theasby

|

| posted on 13/4/09 at 12:46 PM |

|

|

quote:

Originally posted by craig1410

Wood should be fine as long as you seal it with varnish or paint to prevent any vapours becoming trapped or oil soaking in. The type of fire to be

afraid of is when your propshaft fails and rips open the hydraulic lines, fuel lines and opens up the electrics. You then have limited or no brakes

and you have afterburners coming out the back of your tunnel caused by forced airflow through the nosecone mixing with the brake fluid and fuel in the

tunnel. If you are lucky the propshaft will have knocked out the feed to the fuel pump...

Doctor Pepper, what's the worst that can happen...

Oh, and then the propshaft digs into the ground and pole-vaults the car upside down...

You'll be fine! (You didn't make your own propshaft did you?)

Cheers,

Craig.

[Edited on 13/4/2009 by craig1410]

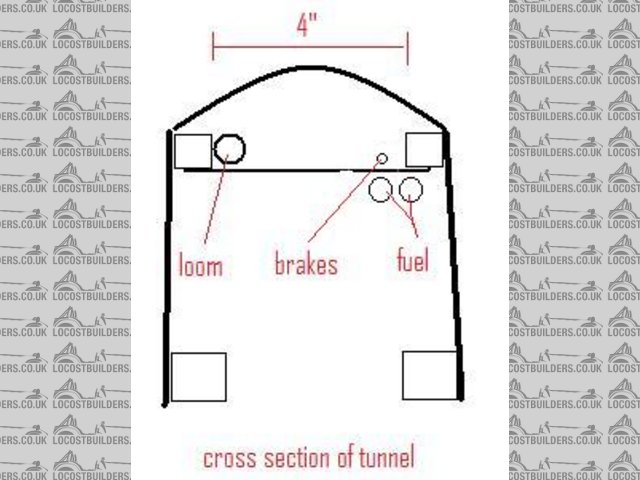

Ive been thinking that all morning Ive been thinking that all morning

"quote Could you not run the loom across the top of the tunnel and the fuel and brake pipes along the bottom? If the loom were to get hot, heat

rises and so wouldnt affect the pipes"

I could but the fuel and brakes both need to start and finish at the top of the tunnel so it would prob cause airlocks if i did, but thanks for the

suggestion. Now decided to run 2 solid fuel lines under the bracket on rhs, brake line on top and loom on top lhs in convoluted tubing.

[Edited on 13/4/09 by andrew-theasby]

Rescued attachment tunnel.jpg

|

|

|