rear light position

blakep82 - 5/12/07 at 06:35 PM

saw this done on a mini in mini world magazine years ago, can't find it now though, not sure if it would be ok for SVA though...

OK, imagine the back panel on a mini where the lights are, remove the lights and weld in a plate that follows the curve of the body. In the plate you

have 2 holes cut with tubes sunk in (not very deep) and 2 (tail/brake and indicator) landrover type lights sunk in. they are only as deep, as to make

the tip of the lens be level with the body.

make sense?

the back of the truck is similar to the curve on a mini, and this is how i wanted my lights in, but i can't work out the SVA manual to see if its

ok.

If i can find a pic of this mini i'll post it...

caber - 5/12/07 at 06:41 PM

Custom car brigade call that "Frenching" don't know why. I would go for it, if they don't pass it at SVA make some timber blocks

to stick the lights out then have them fall off after sva. There are some regs regarding the angle of visibility of indicators, you may get away with

it but no real problem if you don't

Caber

Paul (Notts) - 5/12/07 at 06:42 PM

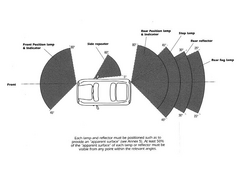

I suspect you would have problems with the horizontal angles of visibility.

Rescued attachment vis1.JPG

blakep82 - 5/12/07 at 06:51 PM

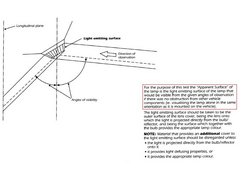

paul, thats what i though, but then i saw this

light surface

seems to be saying that the apparent light surface test should ignore other vehicle components (ie bodywork i guess)

Caber, Frenching in! thats what they called it on the article in mini world all them years ago! didn't know that was a specific term for it.

maybe just screw them to the outside for SVA, and then french the in after then

edit:

like that, but on the corner so on the curved edge

[Edited on 5/12/07 by blakep82]

matt_claydon - 6/12/07 at 08:37 AM

Do you not think that maintaining the required angles of visibility is a good idea? I'd say French them in if you like the look but don't go

so deep that visibility of the lights is compromised.