SVA Warning - brake bias bars

Mark H - 3/5/03 at 08:09 PM

Hi Guys,

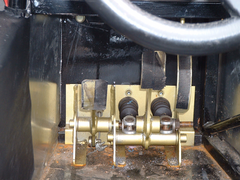

If your car has a brake bias bar - It is a fail if the bar can be adjusted by hand. The sva inspector suggested a nut and split pin in the desired

position.

Please see pic. One more reason to fail gone!

Cheers,

Mark

PS You should see my "matchboxes-covered-in-foam" solution to the issue of sharp bonnet catches! If it passes, I'll show you a

piccy!

Rescued attachment cockpit - bias bar.jpg

Mark H - 3/5/03 at 08:12 PM

The pictures a bit massive-sorry!

Also, have now got rid of the dodgy velcro covers, and put proper grip stuff on (you need something to grip as that is also an SVA fail!

ChrisW - 3/5/03 at 08:27 PM

Is that a Luego pedal box Mark? Looks very similar to the one I have.

Chris

Mark H - 3/5/03 at 09:27 PM

Chris,

It's actually Stuart Taylor, does the job, and looks good. Hmm, apologies for being controversial, but who coped who then?!

Have a good time at Stoneleigh - take reams of photos!

Cheers,

MARK

Markp - 4/5/03 at 04:29 PM

when it comes to the bias bar which way around does it go? there is a short side and a lond side.

Cheers mark

ChrisW - 4/5/03 at 05:57 PM

Have a look in my photo archive. The luego one looks very similar!

What master cylinders did you use btw?

Chris

Findlay234 - 5/5/03 at 09:45 AM

would a nyloc nut do the job, cant really be altered by hand.......???????

Mark H - 5/5/03 at 06:12 PM

Debated this myself. I think that because my SVA man suggested a split pin through, it would be foolish not to put one on.

Of course, every sva man is different and there are no set rules! I would think that as long as it cannot be moved by hand, it will not be

highlighted by the man in the white coat.

merlin - 27/5/03 at 09:13 PM

My SVA inspector insisted it was welded once set so that it can never be adjusted again! It passed!!

Mark H - 28/5/03 at 09:05 AM

Doesn't that mean the bias bar cannot be adjusted for race type situations (surely the point of the bar)? Having said that i cant imagine ever

changing mine.

eddymcclements - 12/8/03 at 10:40 AM

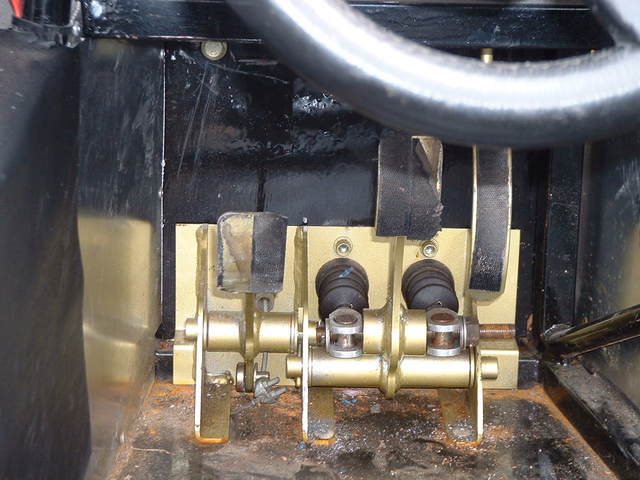

Mark - just looking at your pedal box photos, are your brake master cylinders retained by bolts which thread into rivnuts? Braking parts really need

to be fixed with high-tensile fasteners, and I'm not sure if a Rivnut is really up to the job in that application.

Cheers,

Eddy

Rob Lane - 12/8/03 at 03:50 PM

Have to agree with Eddy, the rivnuts are in danger of stripping with the amount of force applied to the pedal. In this case pushing the bolts away

from rivnut.

I think Dick Axtell came up with some figures for a 5:1 pedal leverage on a cylinder of something in order of 500lbs plus.

blueshift - 12/8/03 at 04:00 PM

Weld nut, pass sva, grind nut off is always an option.

Stu16v - 12/8/03 at 10:21 PM

And to add, the pedal bias will probably not work properly either, with the locking nut and washers bearing onto the 'fork' of the pushrods,

as opposed to the pivot in the middle of the forks, and will not allow the bar to pivot correctly.

StuartA - 13/8/03 at 12:02 PM

quote:

Originally posted by eddymcclements

are your brake master cylinders retained by bolts which thread into rivnuts?

Cheers,

Eddy

What looks like rivnuts on those pics are actually part of the pedal box. Must be OK, otherwise Luego and ST wouldn't make 'em that way

Rob Lane - 13/8/03 at 04:57 PM

I wouldn't trust my life to rivnuts in this application.

I have an ST pedal setup with brake bias bar and it did not come with any rivnuts but it did have the cylinder cutout and mounting holes.

I would be surprised if Ian at ST supplied them this way, he's a capable racer and would know the forces involved.

I used steel rivnuts on my seat bases and just getting in and out has caused two failures of the threads. Admitted they just stripped the threads

around the bolt but stayed in. But then again they weren't subject to any 'pulling' pressure as per the brake cylinder application.

In the pic the pushrod from pedal is acting on cylinder piston and trying to push the whole thing forward under braking. The holding bolts are into

the rivnuts from engine bay side, therefore the pedal pressure is translated as a pushing force on bolt heads and the bolts could pull the threads on

rivnut. Exit any braking!

Just ten pennorth and not meant to offend anyones sensibilities. Mine are bad enough

andyd - 13/8/03 at 05:21 PM

quote:

Originally posted by Rob Lane

I have an ST pedal setup with brake bias bar and it did not come with any rivnuts but it did have the cylinder cutout and mounting holes.

But Rob do they look like Marks? We've got a Luego pedal box (same as ST's) and from that angle I'd bet that they look like

rivnuts.

quote:

Originally posted by Rob Lane

I would be surprised if Ian at ST supplied them this way, he's a capable racer and would know the forces involved.

Agreed, but that's what ours looks like too without modification by us.

wicket - 13/8/03 at 10:49 PM

No Rivnuts on my Luego pedal box !

Rob Lane - 14/8/03 at 07:46 AM

My pedal box is identical except no rivnuts and I've drilled the pedal pads.

They are rivnuts in the photo and you can see the deformation fixing. What is of more concern is that the bolts don't appear to even go through

the rivnut fully.

I've really used my brakes in anger many times and the forces on the pedal are very great.

I just don't wish anyone to get hurt for a simple fastening change.

eddymcclements - 14/8/03 at 03:12 PM

I have an ST-supplied pedal box with pre-drilled holes for Girling/Wilwood master cylinders. The holes didn't have rivnuts fitted and I've

used socket head capscrews to retain the master cylinders.

If you're happy with the set-up, keep it as it is. I'm not telling anyone how to build their own car. Just thought you might want to take

another look at it, taking into account the comments that have been made.

All the best,

Eddy

Rob Lane - 14/8/03 at 09:28 PM

Nicely put Eddy. My comments do seem to somehow come out strong, I don't mean it that way, just trying to be helpful.

Peteff - 15/8/03 at 12:07 AM

It looks o.k. to me. The rivnuts are the right side of the bulkhead. You aren't going to push it through that.

yours, Pete

Rob Lane - 15/8/03 at 07:40 AM

Look at it again Pete.

It's not the rivnuts pulling out but the bolt pulling out of the rivnut if the threads fail. These things are not high tensile.

The pushrod is pushed at force into the cylinder which is trying to be pushed into engine bay. It's currently held by the two bolts on engine

bay side which are threaded part way into the rivnuts.

Sorry, I've gone on about this too much.

If anyones happy with the way they've built their car then that's fine, I've no intention, as Eddy said, to tell anyone how to build

theirs.

Rob

theconrodkid - 15/8/03 at 05:01 PM

Rob/Eddy this forum is for making coments like that,id rather be told my car was unsafe and have chance to fix/modify it than find out the hard way

into a brick wall

andyd - 15/8/03 at 09:21 PM

quote:

Originally posted by theconrodkid

Rob/Eddy this forum is for making coments like that,id rather be told my car was unsafe and have chance to fix/modify it than find out the hard way

into a brick wall

Damn right!

Thanks Eddy and Rob for pointing out something that wasn't obvious to me until now. I will certainly be cutting/drilling out the ones in my

pedal box and replacing them with locknuts! I think that ST and Luego (and anyone else that has this type of pedal box) should be made aware of the

potential risks in using such a fastener. I'll post to the Luego section to see what Grant has to say on the matter.

Rob Lane - 16/8/03 at 08:38 AM

Andy,

I've had a few failures of rivnuts threads or the rivnut itself loosening in hole. To be fair it's usually when the threads are put under

straight pull end strain. They are very good when put under side strain.

I think it was Dick who works for a brake company that pointed out the strains imposed upon the braking pedals/cylinders. I've looked for the

posting but can't find it.

I'm sure there has also been some SVA failures with regard to Sierra type master cylinder mounting on the single thickness bulkhead steel sheet

and it was Dick who pointed out that the whole pedal box arrangement should be very solidly fastened in order to transfer forces involved into braking

effort.

In my original application of a Sierra cylinder I had added two 3mm steel straps welded to sheet metal pedalbox I made to stiffen this, it was

favourably commented on in the SVA test. This was in early days of SVA.

I hadn't given much thought to another solution till now.

Blindingly obvious, just replace bolts/setscrews with longer HT versions that protrude through rivnut and put a nut over threads exposed.

Rob