Seat belt anchorage (SVA)

Donners90 - 24/2/06 at 02:01 PM

If your upper seat belt anchorage is in/on your roll bar, do you have to use a threaded insert (welded on both sides of the bar) or can you use a bolt

right through the bar? I've looked at the SVA manual, and it doesn't specify that you HAVE to use threaded inserts. And indeed, lower seat

belt mounts are usually bolted!

The problem I have is that (apparently) the regulations for seat belt anchorages had changed since my chassis was produced. Grant kindly sent me some

threaded inserts, and said i'd have to cut off the original boss and weld in the new ones. As the roll bar is welded to the chassis, and powder

coated, this may prove awkward to fix. (see pic)

With this in mind I would like to find a solution that would minimise damage to the roll bar, yet still be safe.

As I see there there may be three options open to me:-

1. Drill small hole from top, and bolt through roll bar using current boss as a 'captive nut'.

2. Drill large hole on top of bar, screw bolt into current boss from underneath, drop threaded insert into hole and screw it onto the bolt until it

contacts the current boss, then weld the insert to the roll bar around the top.

3. Cut off current boss, drill hole from top, and weld in threaded insert on top and bottom of roll bar.

I hope to tackle this tomorrow, so any thoughts/ideas/concerns will be greatly appreciated.

Cheers

James

Rescued attachment DSC02112.JPG

David Jenkins - 24/2/06 at 02:05 PM

You are going to have to use an insert anyway, even if it's a plain one, purely for crush-resistance when tightening up the nut & bolt. If

you're going to do that, then you might as well use the threaded ones and make life easier for yourself.

Purely my opinion - YMMV

David

AN AFTERTHOUGHT...

How about a top-hat shaped insert that fits in from the top, through an unwelded hole in the rollbar, with a plain 7/16" hole in the middle. You

could then use a long high-tensile bolt downwards, to screw into the existing boss. The existing boss would act as a captive nut.

The insert would prevent crush, the bolt and insert would hold everything tight, and it would certainly hold together in a crash. A bit of sealant

round the side to prevent water getting in, and Robert's your mother's brother!

Caveat - it's your decision, so be it on your own head...

[Edited on 24/2/06 by David Jenkins]

Donners90 - 24/2/06 at 04:20 PM

Just got off the phone to a VOSA inspector at Chelmsford, and the old boss will have to be cut off and the threaded insert welded through the roll bar

I guess it's best for safety, but I was hoping there was less damaging option. Ah well, out with the grinder.......!!!

DarrenW - 24/2/06 at 04:25 PM

You will also need to ensure the roll bar is securely fixed to the chassis. If welded then no probs. If bolted on you cant use rivnuts. Any bolts that

go through chassis box section will have to have crush tubes fitted.

You say lower seat belt mounts are usually bolted. Mine are threaded bars that are welded onto chassis. Bolts then fix to those - i kind of guess this

is what you meant.

Donners90 - 24/2/06 at 05:00 PM

Yep, the roll bar is firmly welded to the chassis. If it was removable then it would make life soooo much easier. As it is, it'll be difficult

to get to the underside of the bar. I've borrowed an angle drill from work, so top access shouldn't be a problem.

My lower seat belt eyes are bolted through holes in the chassis into load spreading plates. The ones with a nut welded on them. SVA man was happy with

them at least.

Mike S - 24/2/06 at 05:16 PM

James

What is the issue with the arrangement that you have at the moment?

The reason I ask is that the seatbelt top mounts on my GT-1 are like tabs welded to the roll bar cross member that the seat belt anchors are then

bolted through.

Seen loads of cars with this arrangement.

I can't see why this should be a problem, but best to find out before SVA if it is.

Cheers

Mike

oliwb - 24/2/06 at 05:42 PM

Sorry for the hijack....but My roll bar is bolted on to the chassis, the front bolts go through a solid steel plates but the rear are bolted through

thick box section without any crush tubes......No easy way to fit crush tubes that I can think of so will it be OK at SVA or should I weld it to be

sure......Thanks Oli.

Donners90 - 24/2/06 at 06:53 PM

Mike,

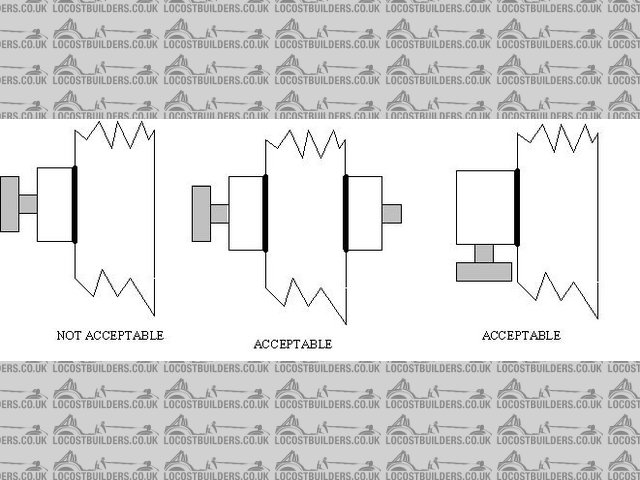

The SVA mentions this in section 5 (I think), from memory the diagrams of acceptable fixings are shown below. Basically, where it is fixed only on one

side of the bar, there is a possibility that it may pull out. With regards the welded tab on your chassis, I guess it conforms to third diagram. Worth

checking with other who have SVA'd GT-1's.

It's very much open to interpretation, but I've been told by my local test station that they will only accept it if it's been welded

through the bar. (middle pic)

Hope this helps

James

[Edited on 24-2-2006 by Donners90]

[Edited on 24-2-2006 by Donners90]

Rescued attachment seatbelt anchorage.JPG