Didn't get to SVA (boo hoo)

Humbug - 3/10/05 at 12:01 PM

Set off at just gone 11 for my SVA appointmetn in Gillingham at 1pm... got about a mile before I was definite I wouldn't get there.

As previously posted, ther is a problem which seems to be that the clutch is slipping - I thought I had fixed it by playing with slack in the cable,

fitting a pedal stop, etc. but you never can really tell till you drive it on the road.

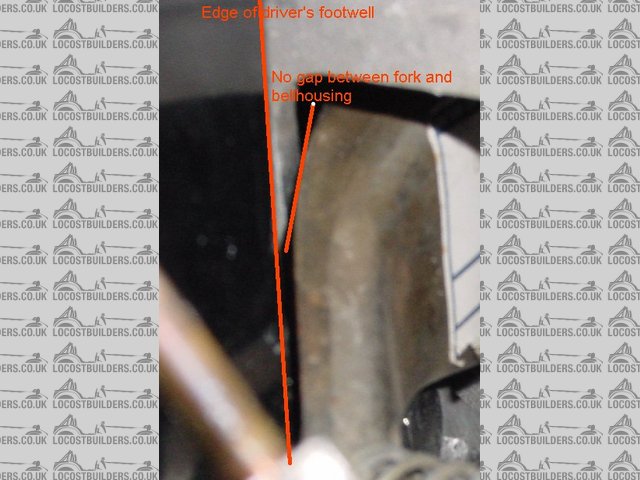

I took it round to my friendly local mechanic who found that the clutch fork?/arm? thingy cannot be moved by hand at all, and is resting on the rear

of the cutout in the bellhousing. This means that the clutch is never actually completely releasing, so the car is never fully in gear (clutch, fork,

cable and bellhosung bought from Fisher Sportscars specifically for the K-series...)

At minimum I am going to have to prop up the engine and gearbox, remove the mount bolts and try to cut out the fork slot a bit more. In addition, I am

going to have to move the whole engine/gearbox assembly forward by half to 1 inch so that the fork can physically move further to the rear, as I have

currently positioned things with minimal clearance from the corner of the driver's footwell... hopefully there's enough length available on

the propshaft to allow me to do that.

plus other irritating things like cutting the tunnel top out to reposition the gearstick further forward.

Any other suggestions?

Cheers

[Edited on 3/10/05 by Humbug]

Rescued attachment 2005-10-03 Locost clutch fork.JPG

BMF - 3/10/05 at 01:37 PM

Same problem on XE bellhousings.

I depressed the clutch so fork out of the way and then ground down the rear of bellhousing where fork sits against.

This then allows it to move further back and release the clutch.

Another trick is to split engine and bellhousing while in car by say 5mm, then insert some washers.

Will have same affect as above but easier as a temporary measure.

ps. It takes bloody ages to do the grinding while engine in as you cannot get to the appeture easily, had to be a small file job in the end!!!

Good luck! Not sure how you are going to sort out the positioning of the fork relative to the chassis though!

zetec - 3/10/05 at 01:46 PM

How about a different release bearing or bending the release arm?

ayoungman - 3/10/05 at 01:54 PM

I think the phrase your looking for sounds like Clucking Bells !

I bet your gutted ! Still, think positive, did everything else work OK ? At least you've driven it on the public roads.

G.Man - 3/10/05 at 02:35 PM

Hydraulic actuator...

Not the type that moves the arm, the type that fits under the bellhousing and actuates along the line of the mainshaft..

MikeR - 3/10/05 at 02:36 PM

hold on .....

Caterham fit the v6 ford type 9, this is 1" longer in the bell housing / input shaft. Is the fisher setup designed around this as well??

Just wondering with your mention of it being around 1".

Might be easier to get a v6 gearbox if thats the problem.

Humbug - 3/10/05 at 03:19 PM

Thanks for the sympathy and suggestions... if I can find a permanent fix that's not too difficult without having to take the engine out I

will be a happy man!

In no particular order:

Glad to hear I'm not the only one (BMF). I think it will be a bugger to get to in order to grind out. Intriguing idea to split the engine and

bellhousing and fill the gap with washers. If that worked, I could move the engine forward a bit and not have the hassle of the grinding, etc. (just a

couple of new holes for the engine mounts). Not sure how permanent that could/would/should be, though?

Not sure how much extra play it really needs.

I don't think it would be easy to bend the release arm - in fact, you wouldn't want it to be easy, I reckon!

New gearbox - definitely engine out for that one! Plus, does the V6 have different splines, etc?

How dodgy would it be to cut a bit of the footwell out? I don't really fancy that idea...

Thanks again, and keep them coming!

Guinness - 3/10/05 at 05:54 PM

Sorry to hear about your problem. Hope you get it sorted quickly and get a re-test booked.

Cheers Mike

Humbug - 3/10/05 at 07:49 PM

Hmmmm. thinking a bit more, how about enlarging the slot in the bellhousing (as before) and cutting an inch or so off the length of the clutch release

arm so it clears the footwell and drilling a new hole in to take the cable?

It would mean that I don't have to move the engine, etc. but how much more strain would be put on the cable by having to pull an inch closer to

the fulcrum?

[Edited on 03.10.2005 by Humbug]

[Edited on 3/10/05 by Humbug]

Surrey Dave - 3/10/05 at 09:40 PM

If you've got access to a welding torch and can get the clutch arm cherry red it would bend OK, shortening the clutch arm will give you a heavier

clutch...