However, if you are not sure of your ground, consult a qualified mechanic / engineeer which I am NOT!.

Brakes are "Mission Critical" components and must be done correctly. Lives can depend upon it. Make sure you get it right.

Made a bit of a rash decision with my front flexis purchase. The lovely (and expensive) Goodridge ones have a male end that is only threaded for about

15mm of it's length.

What this means is that once it's screwed into the calliper there's not enough exposed thread to wind a nut down and lock the flexi against

the Sierra calliper (as the hole is pretty deep).

Would I be right in thinking that it needs a lock-nut where it goes into the calliper? It doesn't have a locknut at the other end of the flexi

line either. Is this a SVA or more importantly general safety problem?

Thanks,

James

[Edited on 12/7/05 by James]

I think you'll find that the thread is either tapered or the union is intended to 'seat' with a copper washer. Either way you

don't need a lock nut.

Mick

I would agree with that. Mine have long threads for the chassis end, and terminate on a thin strip of metal welded to the chassis. I have used lock

nuts here to hold the Male end firmly in the bracket, and then a female brake fitting nut on the ned, again no locknut there. This is normal practice

as per most cars.

However, if you are not sure of your ground, consult a qualified mechanic / engineeer which I am NOT!.

Brakes are "Mission Critical" components and must be done correctly. Lives can depend upon it. Make sure you get it right.

Mine haven't got lock nuts on either. The seal is made by the convex seat on the flexi mating against a concave seat in the caliper, or it is

made using a washer between the flexi and caliper. Mine seem to be sealing on the concave/vex seats...

Cheers

Andy

As you have realised you have the wrong type of fitting for screwing directly into a caliper, you might be able to use a copper washer directly with

out additional fittings although it might involve shortening the threaded end of the pipe fitting. The other way round it is to use a short

intermediate hose with banjo fitting.

The general good practice with hydraulic systems is only one side of the joint should be soft enough to deform to form a seal against a harder

surface -- ie one cant't seal like against like for example by mating a machined steel fiiting directly to another machined steel fitting

or equally bad one shoudn't butt join two soft flaired pipes directly.

Lots of people out in Locost land will have done it and got away with it by making the fittings very tight or using a sealing compound but it

isn't the corrct way to do it.

BT - are you sure James has the wrong fitting. Its difficult to identify from his description. If the flexi has the taper at the bottom and this is

tightening up against a taper in the caliper could the combo be OK? or does a lock nut need to be fitted and his description of 'lack of

threads' suggest it is the wrong type?

James - has the flexi fitting (hex part)bottomed out on the caliper before mating the tapers or do you still have a couple of threads exposed when it

is tightened? Have you bled them up or can you disconnect and take some pics?

Did the flexis come with the lock nuts supplied. On mine the lock nut end fitted to my side panel / copper fitting - here is daft idea - is the flexi

the right way round? Sorry if this is belittling - i do nt know what your set up looks like.

On a slightly related note, anyone know the regs reguarding the conection of the flexi to the fixed pipeing, ie, is there a reg to do with where is

has to be fixed, close to the conection, or is a small distance between conection and fixed pipe allowed ???

Jason

Tried and failed to draw it well enough so I'll take a photo later today.

The system seals and brakes ok. What concerns me is that the flexi will eventually unscrew from the calliper as the wheels turn because there is no

locknut on the calliper end.

Anyway, a picture will tell all.

Cheers,

James

[Edited on 13/7/05 by James]

quote:

Originally posted by Deckman001

On a slightly related note, anyone know the regs reguarding the conection of the flexi to the fixed pipeing, ie, is there a reg to do with where is has to be fixed, close to the conection, or is a small distance between conection and fixed pipe allowed ???

Jason

[img][/img]

Image deleted by owner

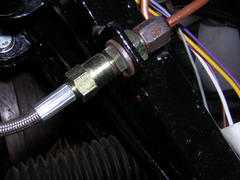

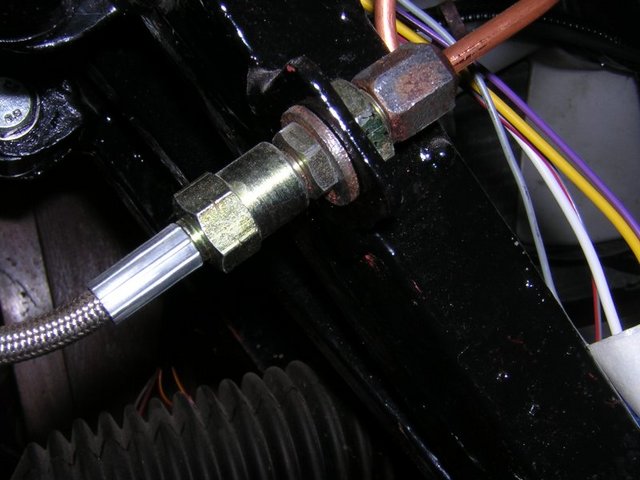

As you can see, after the threaded part that is screwed into the calliper there is a plain shank. Upon this shank sits a nut (arrowed). There's

not enough thread to wind this onto. So I'm thinking of cutting the nut off so it doens't raise SVA questions.

[Edited on 14/7/05 by James]

N/S Front Flexi Car

Because the flexi has a female end I bought a male--->male_bulkhead adapter fitting to screw into it and go through the chassis mounting.

There's no locknut holding the female to the male (although there is one holding the bulkhead adapter to the chassis).

My main worry is that with the lack of locknuts on the flexi am I in danger of the flexi undoing from the calliper or the adapter? SVA?

Thanks

James

[Edited on 14/7/05 by James]

I used rubber flexies and cortina calipers but the fitting is the same, taper to taper, and has no lock nuts. It passed SVA and MOT and has not come loose or leaked since 2001. There is no turning force on it so why should it come loose?

BTTT!

So everyone's cool about this setup then?

Cheers,

James

I cant see anything wrong with it James. Obviously cant see that the tapers are sealed together but looks fine to me. You say the brakes work OK and

as someone has said there are no rotation forces as such so shouldnt try and loosen itself. Maybe just keep an eye on it for a while.

The fact it has lock nut is odd but maybe it is a universal flexi that will suit a different application as well. i dont suppose you have the

goodridge part number so you can look at the application listing????

I got my flexis supplied with the kit so knew they would fit the car and calipers etc but i cant see any maojor differences with what you have done.

i don't think those bleed nipples should be at the bottom though!!

take them off, and show us the taper on the end, and the amount of thread.

tom

james, you haven't put them on the wrong way round have you? ie you've got an adapter on the male end to fit the bulkhead/bracket at the

chassis end and you've got a spare locknut on a sleeve at the brake caliper end?!

just a thought.

Ned.

I must admit that i thought the same as Ned. The part you have screwed into the caliper looks like the bulhead fixing to mate with the rigid piping. Although i cannot understand the female fitting on the other end. Are you absolutely sure the company sent you the correct parts for your application?

looking at the piccies you have calipers on the wrong way round , as already suggested bleed nipples should be at top