suparuss

|

posted on 11/11/03 at 09:55 PM posted on 11/11/03 at 09:55 PM |

|

|

reasurance required (steel question)

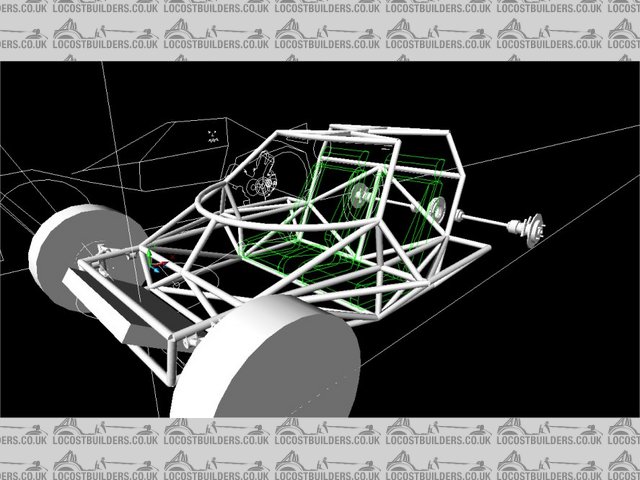

just wondering what opinions are (or experience) on very thin walled steel tube, i plan on using 32mm round erw with 0.91mm wall thickness for my

chassis, its a bike engined car so i want weight low obviously, but would like to get as close to true space frame as poss for stiffness, hence lots

of light tube rather than small amounts of heavy tube. i know welding could pose as a probelm, but im very competent with the mig so can get around

that, any other probs come to mind ie- is the tube TOO light??

ive atatched a picce of the part of the chassis (not finished obviously) tis mid mounted bike engine)

Cheers,

Russ.

Rescued attachment big car chassis.jpg

|

|

|

|

|

Mark Allanson

|

| posted on 11/11/03 at 10:24 PM |

|

|

As an ex pro welder, the strength of steel is often underestimated, you should be fine as long as non of the lengths are particularly long and

everything is triangulated and load paths are directed at multiple joints

Your front end, which needs to be the strongest has no triangulation, but as you said its not finished yet - looks really good

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

Alan B

|

| posted on 11/11/03 at 10:58 PM |

|

|

I think the biggest problem will be the practical aspects.....tube that thin will need meticulous joint preparation...and obviously very good

welding...

The theory is right .....bigger diameter and thinner wall is much stiffer than smaller diameter...

Good luck and keep us informed.

When I used to make a lot of spaceframes the thinnest we would normally use was 18g which is about 1.2mm IIRC....

|

|

|

aus-sambo

|

| posted on 12/11/03 at 02:00 AM |

|

|

idea convergence

Consider making the tube thinner and thinner, and adding more and more of them. Eventually you converge to a monocoque shape made of sheet material

instead. Have you considered making the central tub at least out of sheet, with a space frame box at front and rear?

Am conspriring to do this sometime in the next few years with a bike engine also. Lotus' elise is an interesting place to start - you may want

to check out this URL.

http://www.sandsmuseum.com/cars/elise/thecar/chassis/

You dont necessarily need to use all aluminium - this example of a 68kg chassis may be a bit overdone. If your bike engine has more go than the rover

engine the elise runs, you're probably in good shape.

I reckon the hayabusa engined concept car from the tokyo 2001 motor show might get you thinking too - try a google search on "GSXR/4" or

go to

http://www.graziosi.net/mario/gallery/GSXR/gsxr4_1

Good luck and let me know what you come up with - you may save me a lot of work down the track!!!

yee har - it's the lawn ranger!

|

|

|

suparuss

|

| posted on 12/11/03 at 06:07 PM |

|

|

thanks for you input, feel a lot better now

its all a bit rough a the moment i dont know the actual width yet cos quaife wont send me a drawing of their diff, and im trying to get some

dimensions for the windscreen from some lancia stratos owners, then i should be able do some final designs!

its and interesting idea aus-sambo but im not sure i could gain anything without converting entirely to an alluminium chassis, steel isnt strong

enough in really thin sheet, tho you have put a bee in my bonnet about using stressed skin construction around the inside of the cockpit, i can save

on a few tubes, and on alluminium for the interior, so that is worth looking into.

building the car will be another matter though, i get my new house (with a workshop)in a couple of weeks so after moving the tiny bathroom into the

one of the bedrooms, using the bathroom as a staircase into the loft which ill convert into a big bedroom, and fit a new kitchen not to mention

decorating! then ill be able to start the car  providing i dont decide to sell the house which depends how much the value goes up providing i dont decide to sell the house which depends how much the value goes up

cant wait.

Cheers,

Russ.

|

|

|