sgraber

|

| posted on 25/10/04 at 05:11 PM |

|

|

Opinion on headlamp cover shape

Would some of you care to comment on the shape of the headlamp cover I have layed out in black on the following photo?

Thanks.

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

|

|

Cita

|

| posted on 25/10/04 at 05:42 PM |

|

|

I dont know how else to put it Steve but in my opinion it looks too flat.

|

|

|

Spyderman

|

| posted on 25/10/04 at 05:45 PM |

|

|

If you can use the lights and covers from your first version in Bodywork section then you will have cracked it. They look great and suit the style of

car.

Your latest rendering needs to move forward and angle down a little. So that the lower edge of the cover is either horizontal or sloping downwards to

the front when viewed from the side. You don't want any angles going upwards at the front.

All in my humblest of opinions of course!

Terry

Spyderman

|

|

|

sgraber

|

| posted on 25/10/04 at 06:02 PM |

|

|

It's an optical illusion Terry.

Damn photos... they just don't show the shape as well as they should.

Cita, The perspex may appear slender, but the area for the actual lights is deeper than you might think.... (you are looking at spray paint on the

bodywork...)

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Alan B

|

| posted on 25/10/04 at 06:21 PM |

|

|

Steve, looks good to me......

Any thoughts on how you will make them?

|

|

|

Spyderman

|

| posted on 25/10/04 at 06:25 PM |

|

|

Ok I'll get my coat!

Spyderman

|

|

|

Cita

|

| posted on 25/10/04 at 06:35 PM |

|

|

The side picture looks much better Steve!!!

Front picture gives the impression that the nose doesnt "dive" as much as in the side picture.

Sorry that i have sounded on the negative side.

Looks good!!!!!

|

|

|

sgraber

|

| posted on 25/10/04 at 07:07 PM |

|

|

No worries guys,

my thought is that the photos of the flat white surface just kills the depth perception. Then my little mini-digital camera screws it up some more

with the angle of the lens.

I had some friends come over to help work on the car this weekend and their first words were WOW, it looks MUCH better in person than it does in the

photos. That's because the fotos make it look so very flat... A big drawback of non face-to-face communication IMHO.

Alan, the plan... ahh the plan... is to create two separate molds. (Probably cut directly off the car and modified to suit)

To shape a cover: Cut a large rectangle of plexi, drape it over the former, heat up the plexi with a heat gun and pull it down to shape, then trim the

edges... Otherwise, make a female mold, and use heat and vaccum to suck the plexi into the mold.

I have a couple of websites bookmarked that show guys forming windshields for motorcycles in a similar fashion (heat).

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Hellfire

|

| posted on 25/10/04 at 07:18 PM |

|

|

OMG

It is SO taking shape!!!! Looks brilliant Steve!

I tend to agree with Cita... unless the headlight lens goes towards the top of the cover lens. I like flat lights look so cool.... good luck with

mounting them.

Great job - keep it up.... it's great seeing your progress!!!!

|

|

|

Ben_Copeland

|

| posted on 25/10/04 at 07:47 PM |

|

|

Looks excellent, keep it as it is... as long as it can pass regs

Ben

Locost Map on Google Maps

Z20LET Astra Turbo, into a Haynes

Roadster

Enter Your Details Here

http://www.facebook.com/EquinoxProducts for all your bodywork needs!

|

|

|

sgraber

|

| posted on 25/10/04 at 08:00 PM |

|

|

quote:

... as long as it can pass regs

The centre point of the low beam needs to be at least 24" above ground plane. I have them sitting at 22" for the best fit in the

wheelwell, but! I can raise the car up to 3" using the adjustable suspension if they decide to be anorak about it.  and I could raise ride

height even more by temporarily substituting the current pullrods with even longer ones. and I could raise ride

height even more by temporarily substituting the current pullrods with even longer ones.

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

derf

|

| posted on 25/10/04 at 08:02 PM |

|

|

I can agree with cita, looks too flat, I think it's just because the headlight is too long. I also am kinda on edghe about the front air ducts,

it seems too buck toothed.

I just kept thinking it should be straight up and down, rather than angled like that. I like the idea though of it being angled from front to BAck

(going down in the back-bottom) making it look like a front splitter, but the sideways angle just struck me as being wrong.

anywhoo, here is my latest rendering of your car, some small changes like the front air ducts, and I made the headlight smaller. Oh yeh, I also added

you in there with my hi-tech photo morphing analizer (otherwise known as MS paint)

[img][/img]

|

|

|

Hugh Jarce

|

| posted on 26/10/04 at 04:18 AM |

|

|

quote:

Originally posted by sgraber

To shape a cover: Cut a large rectangle of plexi, drape it over the former, heat up the plexi with a heat gun and pull it down to shape, then trim the

edges... Otherwise, make a female mold, and use heat and vaccum to suck the plexi into the mold.

I have a couple of websites bookmarked that show guys forming windshields for motorcycles in a similar fashion (heat).

Steve, I've had good success in the past with briefly submerging the acrylic sheet in a tray of boiling water and then "flopping" it

over the required object. When it's cool, you can then flopp another sheet inside the first (male mould) piece for the finished article.

If the mould is very deep, it pays to drill a few holes in it prior to flopping the second sheet in. It lets some hot air and vapour out so you

don't get any unplanned dents in the final part.

Also, if it is a deep part, it can help to fill the second sheet with more boiling water as it flops down into the mould.

The pay isn't very good , but the work's hard.

|

|

|

malakiblunt

|

| posted on 26/10/04 at 10:54 PM |

|

|

hay steve its your car make it the you want it!

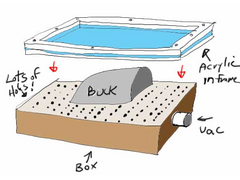

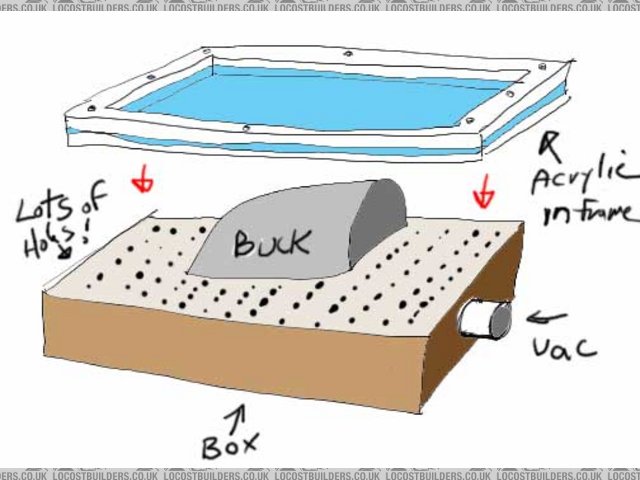

as to makeing them its prety eisesy to make a vacum former.

just get a shallow strong box(knock it up out of plywood if you cant find one) the top panel needs to have lots of little holes in u want to find

some hardboard or may be steel mesh or soething. And put draft excluder round the top edge as a seal. and duct tape the hose from a vacum cleaner

into the box.

then make 2 wooden frames that fit on the top of the box and screw then together with a piece of acrylic in between so youve got what looks like a

window. put the acrylic inits frame under the grill til it goes flopppy turn the vacum on and push the frame down over your buck of your headlight

cover (which you made earlier and sat in the middle of the peforated box top)

and soon as the acrylic cools turn of the vacum and one headlight cover.

actuly now ive writen that down dont sound quite so quick!

so instead make the frame and plug as above but instead of the box make a cut out in a pice of thick board to the profile of the botom of the plug

plus the thickness of the acrylic. heat it up lay it over the hole then push the plug through till its level with the base.

i can email u a diagram if that makes no sence!?

remember you need to start with thicker plastic than you want the finished article as it gets thiner as you form it.

[Edited on 26/10/04 by malakiblunt]

|

|

|

sgraber

|

| posted on 27/10/04 at 04:33 AM |

|

|

Derf, I do like the look of your front grille. I may be changing mine a bit because it does look like a buck-toothed bitch...

Hugh, Malakiblunt, Those are both good ideas and I am going to do some experimentation here in a few days and get back to you.

Here's what I gather from what you have said. I like the idea of flopping a piece of acrylic (boiled to about 250f) over the bodywork that I

currently have, and letting it harden. When that cools I would drill a large number of holes in it and build a sealed vaccum box around its outside.

So it's like the shape forms a cup inside the box. Then I can flop another piece of acrylic on top of the box and use vaccum to pull it tight to

the inside of the first piece of acrylic. Trim the edges and Viola, a headlamp cover.

Does that sound about right? Missing something? No need for optical perfection right?

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Hugh Jarce

|

| posted on 27/10/04 at 04:47 AM |

|

|

Steve, that's about spot on. I would be careful with the amount of vacuum to hole size ratio, as you could end up with a cover that looks like

bubble-wrap!

I have done vacuum moulding before, but I didn't use a vacuum when flopping the hot acrylic. I just let gravity and occasional additions of hot

water do the job. I would experiment though.

The pay isn't very good , but the work's hard.

|

|

|

sgraber

|

| posted on 27/10/04 at 06:10 AM |

|

|

Hugh, this is the type of advice that makes this website such a jewel. Thanks much!

Graber

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

malakiblunt

|

| posted on 27/10/04 at 11:34 PM |

|

|

yeah experiment thats always the best way thers so many ways to skin the proverbial feline you need to find what works for you.

your right optics arnt very important but i have herd that you can get strange distortions with covers, the E type jag aperently.weather it maters i

dont know, but jag scraped them on the mark2.

more importantly is you need them to look smooth as youve set your self such a high standard with the rest of your project1 cant muck it up now with

woberly covers.

with the vac forming the buck is a positve of what you want and doesnt have any holes it sits on the base board which has the holes in so you dont get

the buble wrap look.

i take it your going to make a mold from your body to then lay up the grp panels? so why not take a second cast from the mold of the headlamp area and

use that as the vacum buck?

Rescued attachment vacform.jpg

|

|

|

sgraber

|

| posted on 27/10/04 at 11:47 PM |

|

|

Well Malik, that's a nifty idea too and I'd say well suited to making more than one set!

This cat better have 9 lives...

Graber

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

malakiblunt

|

| posted on 28/10/04 at 12:08 AM |

|

|

yeah ive gone and got caried away again!

but then once set up for vac forming you could make a 1/10 scale model of the graber mobeil

and flog um to the kids as bodys for ther rc cars

|

|

|

sgraber

|

| posted on 28/10/04 at 12:50 AM |

|

|

I thought maybe a short video would better show the headlamp cover shape? You can also see how much work I need to finish up the Passenger Side. The

driver side is basically finished and ready for primer/sanding steps.

Link to Short Video Here

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

derf

|

| posted on 28/10/04 at 01:02 PM |

|

|

That video made a few things very clear to me,

1. It looks alot (from the front) like a ferrari

2. I also figured out what was bugging me about the headlight shape, for some reason it looks like the outside lower rear corner of the headlight

cover is too close to the edge of the wheel arch.

|

|

|

Cita

|

| posted on 28/10/04 at 05:33 PM |

|

|

The inner sides of the covers are a bit to straight Steve and in my opinion they are a bit too long to.

I would round them off in the front in some sort of eliptical form.

I really starting to look like bashing car Steve!!!

|

|

|

derf

|

| posted on 28/10/04 at 08:54 PM |

|

|

I have a BFH if you really want to bash his car

(BFH=Big Fing Hammer)

|

|

|

Cita

|

| posted on 29/10/04 at 08:21 PM |

|

|

My English...oh well

|

|

|